Medical application of pregabalin

A technology of pregabalin and its use, which is applied in the field of pregabalin for treating cerebral ischemia or cerebral infarction, and achieves the effects of delaying transformation, improving quality of life and survival time, and treating and preventing definite effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

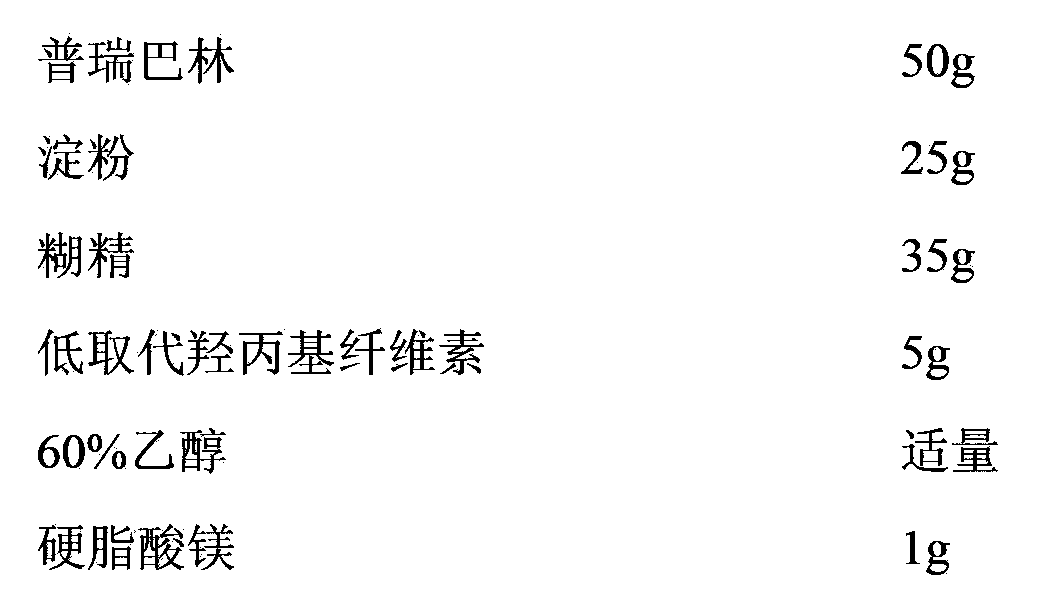

[0018] Embodiment 1 Pregabalin tablet preparation

[0019]

[0020] Preparation process: Weigh the prescribed amount of pregabalin, starch, dextrin and low-substituted hydroxypropyl cellulose and mix evenly. Another appropriate amount of 60% ethanol is added to the mixed powder, mixed evenly to make a soft material, granulated through a 16-mesh sieve, and dried below 60°C. After the drying is completed, use an 18-mesh sieve to carry out granulation, sieve out the fine powder in the dry granules, mix with the sieved magnesium stearate, and then mix with the dry granules evenly, and press into tablets to obtain the product.

Embodiment 2

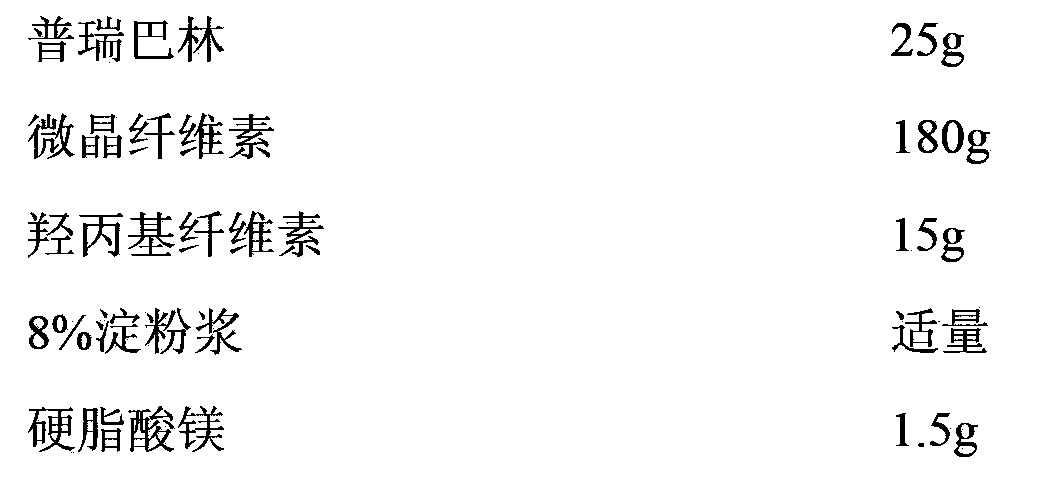

[0021] Embodiment 2 pregabalin tablet preparation

[0022]

[0023] Preparation process: Weigh the prescription amount of pregabalin, microcrystalline cellulose and hydroxypropyl cellulose and mix evenly. Take another appropriate amount of 8% starch slurry, add it to the mixed powder, mix well and make soft material, pass through a 16-mesh sieve to granulate, and dry below 60°C. After the drying is completed, use an 18-mesh sieve to carry out granulation, sieve out the fine powder in the dry granules, mix with the sieved magnesium stearate, and then mix with the dry granules evenly, and press into tablets to obtain the product.

Embodiment 3

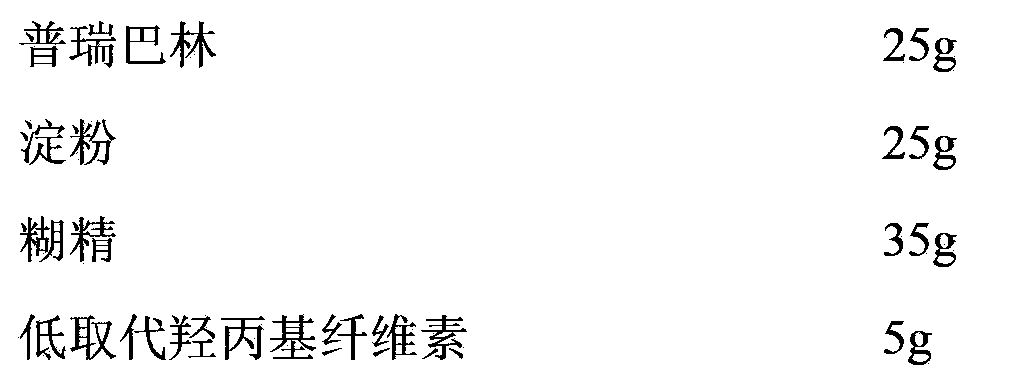

[0024] Embodiment 3 pregabalin tablet preparation

[0025]

[0026]

[0027] Preparation process: Weigh the prescribed amount of pregabalin, starch, dextrin and low-substituted hydroxypropyl cellulose and mix evenly. Another appropriate amount of 60% ethanol is added to the mixed powder, mixed evenly to make a soft material, granulated through a 16-mesh sieve, and dried below 60°C. After the drying is completed, use an 18-mesh sieve to carry out granulation, sieve out the fine powder in the dry granules, mix with the sieved magnesium stearate, and then mix with the dry granules evenly, and press into tablets to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com