Hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve the problems of low strength, poor toughness of porous ceramics, easy brittle cracking, etc., and improve fracture toughness. and strength, the preparation process is simple, and the effect of improving the hydrogenation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

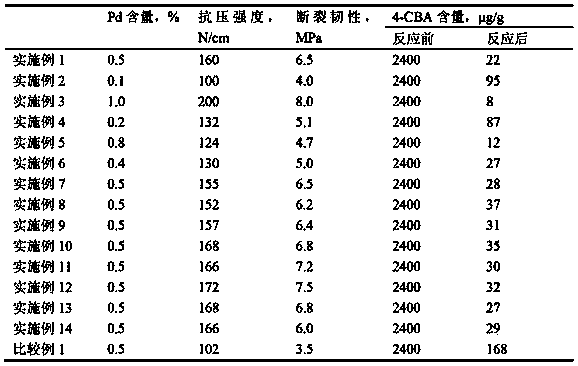

Examples

preparation example Construction

[0040] According to the present invention, provided with TiO 2 The preparation method of the hydrogenation catalyst supported by porous ceramics comprises the following steps:

[0041] (1) Will ①TiO 2 Powder, ②pore-forming agent, ③modifier, and ④dilute nitric acid are contacted to obtain a contact product;

[0042] (2) extruding the contact product to obtain a shaped product;

[0043] (3) Roasting shaped products to obtain TiO 2 porous ceramic carrier;

[0044] (4) the TiO obtained in step (3) 2 The porous ceramic support contacts the phenolic resin solution and dries to obtain the TiO modified on the surface of the phenolic resin 2 porous ceramic carrier;

[0045] (5) the modified TiO obtained in step (4) 2 The porous ceramic support contacts the solution containing the Pd compound, so that the palladium-containing compound is supported on TiO 2 On a porous ceramic carrier, a catalyst precursor is obtained;

[0046] (6) The catalyst precursor obtained in step (5) is ...

Embodiment 1

[0061] (1) Will ①TiO 2 100 parts of powder, ②15 parts of pore-forming agent methylcellulose, ③Modifier ZrO 2 10 parts, ④ 40 parts of dilute nitric acid with a concentration of 10% are mixed and kneaded evenly; the kneaded material is extruded and cut into strips of 5-6 mm; the strips are obtained by drying at 120°C and roasting at 1250°C for 4 hours TiO 2 porous ceramic carrier;

[0062] (2) Add 10 parts of phenolic resin to 40 parts of absolute ethanol, stir for 1 hour to obtain a uniform and transparent solution;

[0063] (3) TiO obtained in step (1) 2 The porous ceramic carrier is impregnated with the solution obtained in step (2), and the impregnation time is 5h; the TiO with phenolic resin surface modification is obtained by drying at 100°C. 2 porous ceramic carrier;

[0064] (4) the TiO obtained in step (3) 2 The porous ceramic support is impregnated with a solution containing palladium chloride, so that palladium chloride is loaded on TiO 2 On a porous ceramic ca...

Embodiment 2

[0068] (1) Will ①TiO 2 100 parts of powder, ②5 parts of pore-forming agent carbon fiber, ③Modifier ZrO 2 5 parts, ④ 50 parts of dilute nitric acid with a concentration of 5% are mixed and kneaded evenly; the kneaded material is extruded and cut into strips of 5-6 mm; the strips are dried at 120°C and roasted at 900°C for 4 hours to obtain TiO 2 porous ceramic carrier;

[0069] (2) Add 10 parts of phenolic resin to 50 parts of absolute ethanol, stir for 1 hour to obtain a uniform and transparent solution;

[0070] (3) TiO obtained in step (1) 2 The porous ceramic carrier is impregnated with the solution obtained in step (2), and the impregnation time is 1h; after drying at 100°C, the TiO with phenolic resin surface modification is obtained. 2 porous ceramic carrier;

[0071] (4) the TiO obtained in step (3) 2 The porous ceramic support is impregnated with a solution containing palladium acetate, so that palladium acetate is loaded on TiO 2 On a porous ceramic carrier, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com