In-situ polymerization method of nano starch/SiO2 composite particles

A technology of composite particles and nano-starch, which is applied in the direction of silicon oxide, etc., can solve problems such as in-situ polymerization of composite particles that have not yet been seen, and achieve good market application prospects, simple preparation methods, and low prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

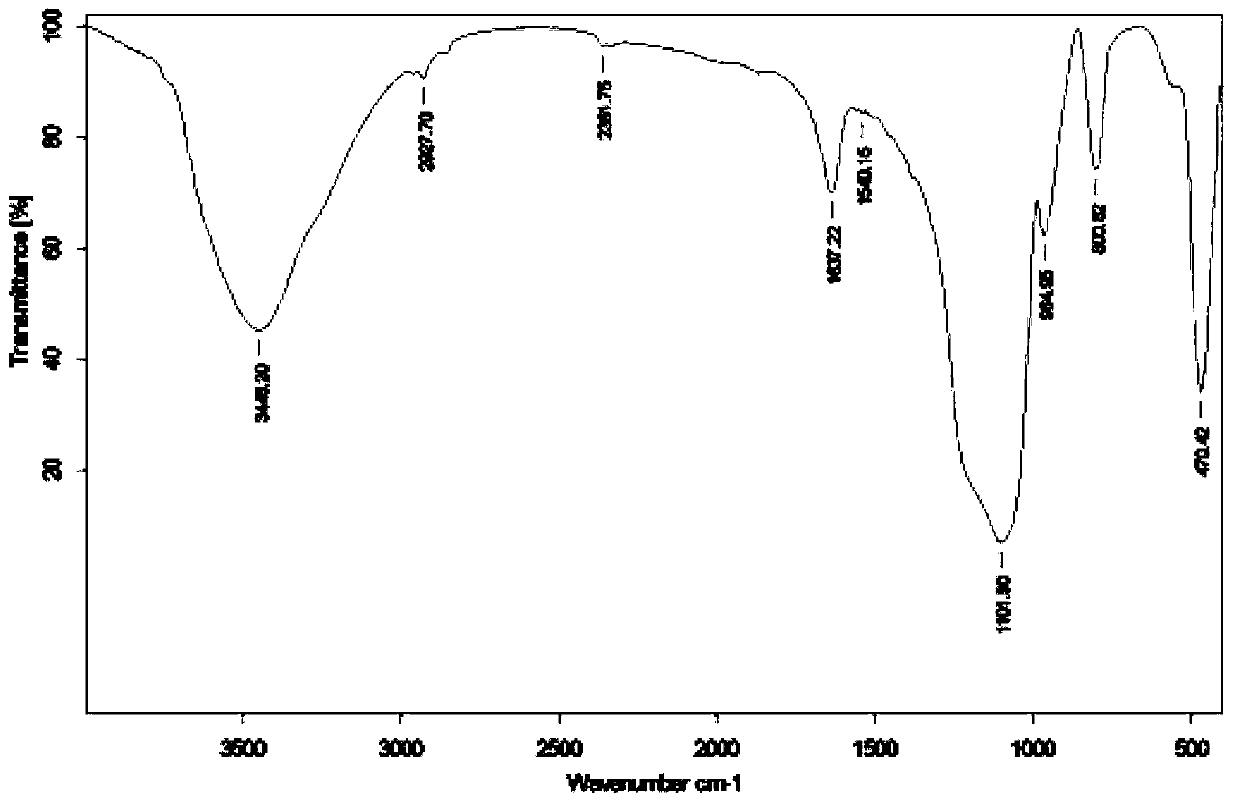

Image

Examples

Embodiment 1

[0022] 1. Starch hydrolysis

[0023] Weigh 10g of starch, add 90ml of distilled water, heat and stir in a water bath at 90°C, gelatinize for 10 minutes, add 15ml of 37% HCl solution, continue heating and stirring to form a transparent starch hydrolyzate, then add 1.5g of NaCl, Let cool and set aside.

[0024] 2. In situ polymerization

[0025] Weigh 35g of industrial water glass with a Baume degree of 0.45 and a modulus of 2.8, add 140ml of water to dilute it into a 20% aqueous solution, settle it statically, take the supernatant, and then press nano starch / SiO 2 10% of the theoretical output of composite particles is added to Si69, according to nano starch / SiO 2 Add 1.5% of the theoretical output of composite particles into sodium dodecyl sulfonate; under the condition of heating in a water bath at 90°C, control the dropping rate of 70 drops / min, add dropwise to the starch hydrolyzate and keep stirring. After the reaction, use HCl Or adjust the pH value to 6 with NaOH, age...

Embodiment 2

[0029] 1. Starch hydrolysis

[0030] Weigh 5g of starch, add 95ml of distilled water, heat and stir in 80°C water bath, gelatinize for 10min, add 12.5ml of 37% HCl solution, continue heating and stirring to form a transparent solution, then add 1.2g of NaCl, cool, and set aside.

[0031] 2. In situ polymerization

[0032] Weigh 35g of industrial water glass with a Baume degree of 0.45 and a modulus of 2.8, add 100ml of water to dilute it into a 25% aqueous solution, settle statically, take the supernatant, and then, press nano-starch / SiO 2 15% of the theoretical output of composite particles is added to KH550, according to nano starch / SiO 2 Add 0.8% of the theoretical output of composite particles into sodium dodecylbenzenesulfonate; under the condition of heating in a water bath at 85°C, control the dropping rate of 60 drops / min, add dropwise into the starch hydrolyzate and keep stirring. After the reaction is over, Use HCl or NaOH to adjust the pH value to 5.5, age for 2h,...

Embodiment 3

[0036] 1. Starch hydrolysis

[0037] Weigh 20g of starch, add 90ml of distilled water, heat and stir in a water bath at 85°C, gelatinize for 10 minutes, add 17.5ml of 37% HCl solution, continue heating and stirring to form a transparent solution, then add 1.3g of NaCl, cool, and set aside.

[0038] 2. In situ polymerization

[0039] Weigh 35g of industrial water glass with a Baume degree of 0.45 and a modulus of 2.8, add 160ml of water to dilute it into an 18% aqueous solution, settle still, take the supernatant, and then press nano starch / SiO 2 Add Si69 to 8% of the theoretical output of composite particles, according to nanostarch / SiO 2 2.0% of the theoretical output of the composite particles was added to sodium dodecylsulfonate; under the condition of heating in a water bath at 80°C, the dropping rate was controlled to be 80 drops / min, and added dropwise to the starch hydrolyzate with constant stirring. Adjust the pH value to 5.5 with HCl or NaOH, and age for 2 hours to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com