Method for recovering elementary substance arsenic from arsenic sulfide slag

A technology of arsenic sulfide and recycling bills, applied in the direction of improving process efficiency, etc., can solve the problem of high cost, and achieve the effects of easy control of operating conditions, significant economic and environmental benefits, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

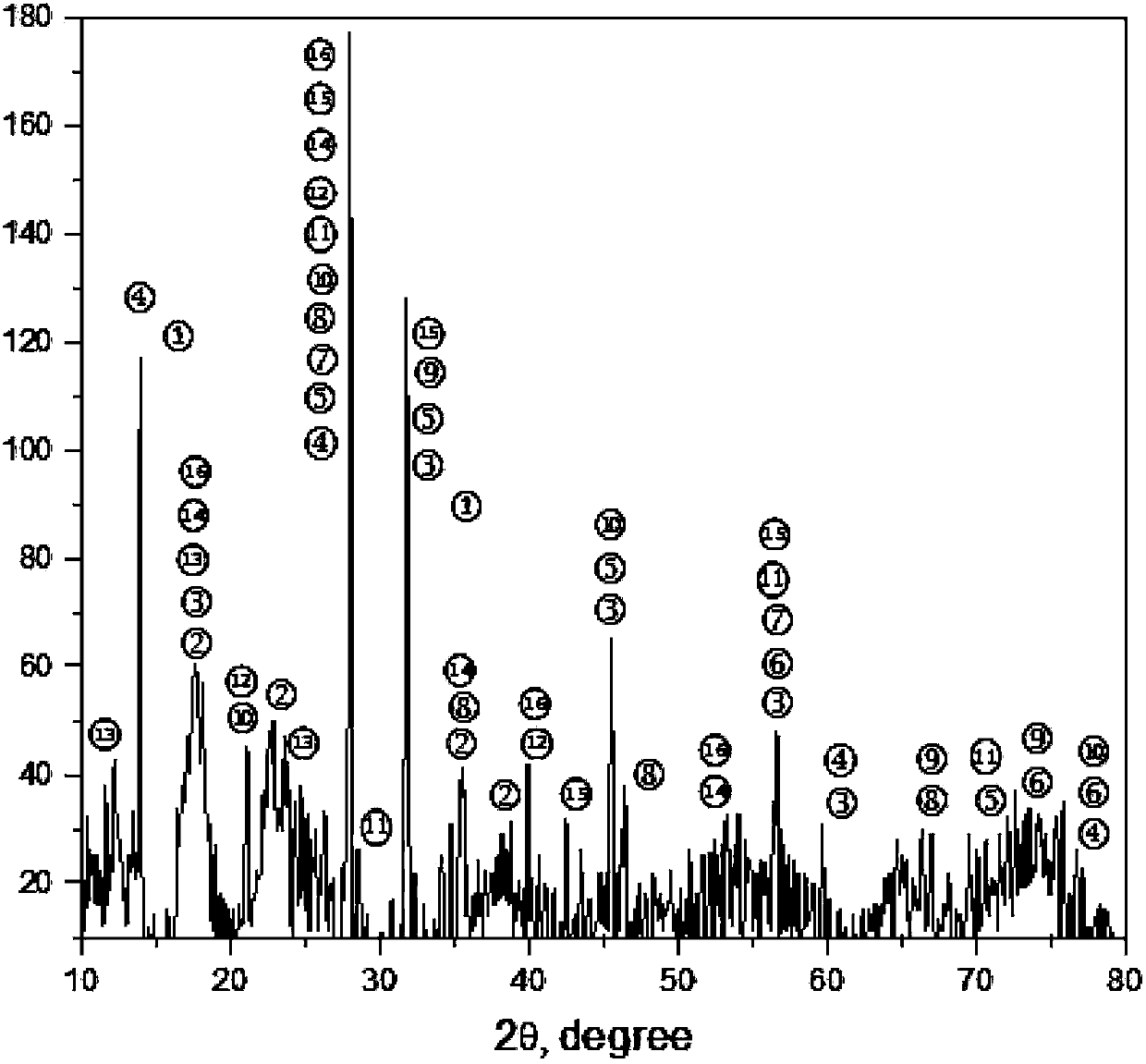

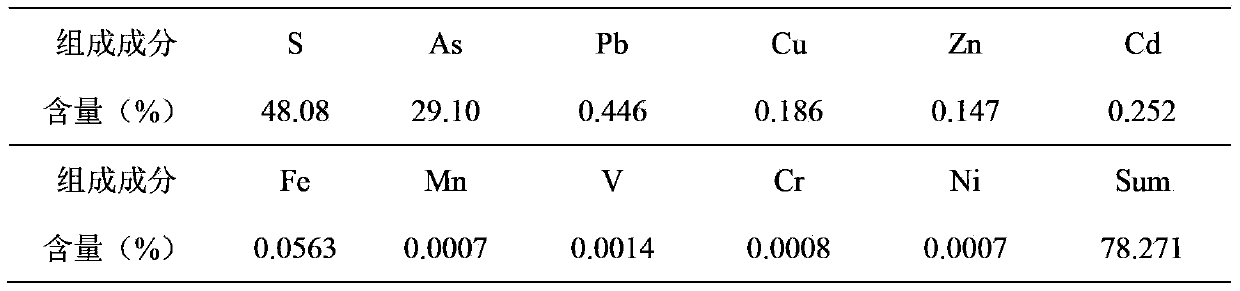

Image

Examples

Embodiment 1

[0031] A method for recovering elemental arsenic from arsenic sulfide slag, comprising a two-stage process "oxidative desulfurization leaching-acidification reduction", the specific steps are as follows:

[0032] (1) Take 5g of arsenic sulfide slag in a 250mL Erlenmeyer flask, add 100mL of distilled water, place the Erlenmeyer flask in a water bath and heat it to 75°C and keep it constant; add sodium hydroxide powder under stirring until the pH of the solution is 8-9; Then add 35mL of 30% hydrogen peroxide dropwise at a constant speed, and finish dripping in 40 minutes. After the dropping, rinse the bottle wall with a small amount of distilled water so that the liquid volume does not exceed 150mL. Continue to stir and react for 6 hours. The elemental sulfur generated during the reaction will have a large amount of conjunctiva. , rinsed repeatedly with distilled water, and the liquid volume was about 200mL after the reaction;

[0033] (2) After the reaction is completed, filter...

Embodiment 2

[0036] A method for recovering elemental arsenic from arsenic sulfide slag, comprising a two-stage process "oxidative desulfurization leaching-acidification reduction", the specific steps are as follows:

[0037](1) Take 10g of arsenic sulfide slag in a 500mL Erlenmeyer flask, add 200mL of distilled water, place the Erlenmeyer flask in a water bath and heat it to 75°C and keep it constant; add sodium hydroxide powder under stirring until the solution pH=8~9; Then add 70mL of 30% hydrogen peroxide dropwise at a constant speed, and finish dripping in 40 minutes. After the dropping, rinse the bottle wall with a small amount of distilled water so that the liquid volume does not exceed 300mL, and continue to stir for 6 hours. The elemental sulfur generated during the reaction will have a large amount of conjunctiva. , rinsed repeatedly with distilled water, and the liquid volume was about 400mL after the reaction;

[0038] (2) After the reaction is completed, filter with medium-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com