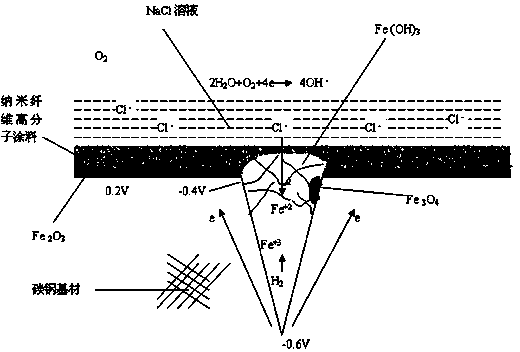

Nanofiber heavy-duty anticorrosive composite material and application thereof in wet desulfurization concrete chimney

A technology of nanofibers and composite materials, which is applied in the direction of combustion methods, chemical instruments and methods, and treatment of combustion products. It can solve the problems of glass flake layer leakage, loss of anti-corrosion function, and limited adhesion, so as to eliminate potential safety hazards, Excellent adhesion and high anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] The nanofiber heavy-duty anti-corrosion composite material and its application in the wet desulfurization concrete chimney are carried out according to the following steps:

[0139] (1) Requirements for pre-treatment of the inner wall of the chimney 1: Remove the original anti-corrosion layer on the inner wall of the chimney, repair the damaged acid-resistant brick lining, and use KPI-acid-resistant mortar to smear the entire inner wall of the chimney to achieve better construction surface smoothness. The construction surface is required to be clean and dry. All visible grease, oil, dust, lubricants and other pollutants must be completely removed, free of acids, alkalis, salts and soaps;

[0140] (2) Interface agent preparation 2: Prepare according to the instruction manual of HJF-01D desulfurization equipment special nanofiber heavy-duty interface agent of Xi'an Huajie Aohai New Material Company, and the preparation ratio is: interface agent: curing agent: solvent = 5:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com