Method for preparing albumen powder from hot-pressing vegetable fat cake

A vegetable oil and protein powder technology, which is applied in the protein composition of vegetable seeds, protein food ingredients, food science, etc., can solve the problems of small application range, achieve good functional properties, promote protein dissolution, and light color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

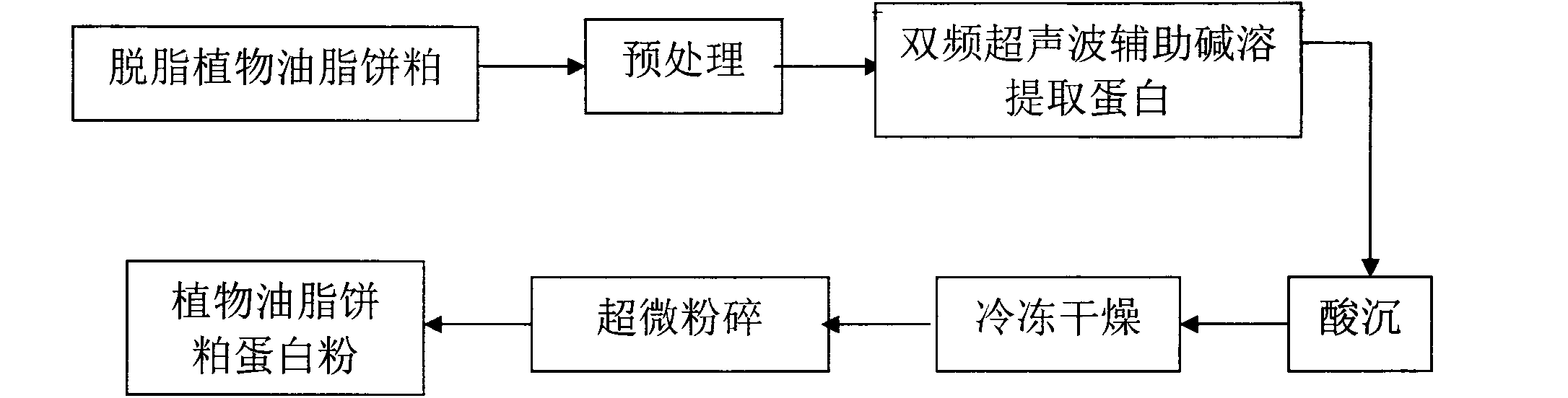

[0024] Embodiment one: the method for preparing protein powder from hot-pressed vegetable oil cake

[0025] The cake after oil extraction is used as the raw material, and the vegetable oil cake protein is assisted by dual-frequency ultrasonic radiation treatment technology, and at the same time, the heat-denatured vegetable oil cake protein is refolded, and the vegetable oil cake is further improved by using ultra-fine pulverization technology. Functional properties such as protein solubility, dispersibility, water and oil retention, emulsification and emulsification stability, foaming and foaming stability, etc., improve the quality of protein powder products.

[0026] Specifically, the present invention uses dual-frequency ultrasound combined with ultrafine pulverization to prepare protein powder from hot-pressed vegetable oil cake, and the specific preparation method steps are as follows:

[0027] (1) Pretreatment: Degrease and dry the vegetable oil cake after extracting the ...

Embodiment 2

[0034] Embodiment two: the method for preparing protein powder from hot-pressed vegetable oil cake

[0035] (1) Pretreatment: degrease and dry the sunflower seed cake after oil extraction, pulverize it with a pulverizer, and pass through a 40-mesh sieve to obtain 1000 g of sunflower seed meal powder.

[0036] (2) Dual-frequency ultrasonic-assisted alkali-solution extraction of protein: use the above preparation to obtain pretreated raw materials, add deionized water to the sunflower seed meal powder according to the mass ratio of sunflower seed meal powder: deionized water of 1:15, and adjust with NaOH The pH value is 8.0, the temperature is 40°C, and dual-frequency ultrasonic treatment is used during the protein extraction process. The dual-frequency ultrasonic composite frequency is 20kHz / 35kHz, and the sound intensity is 0.1W / cm 2 , the action time is 5s, the intermittent time is 5s, and the extraction is stirred and extracted for 60min according to the above conditions. A...

Embodiment 3

[0041] Embodiment three: the method for preparing protein powder from hot-pressed vegetable oil cake

[0042] (1) Pretreatment: Degrease and dry the flaxseed cake after extracting oil, pulverize it with a pulverizer, and pass through a 60-mesh sieve to obtain 1000 g of flaxseed meal powder.

[0043] (2) Dual-frequency ultrasonic-assisted alkali-solution extraction of protein: use the above preparation to obtain pretreated raw materials, add deionized water to the flax seed meal powder according to the mass ratio of flax seed meal powder: deionized water is 1:25, and adjust with NaOH The pH value is 9.0, the temperature is 45°C, and dual-frequency ultrasonic treatment is used during the protein extraction process. The dual-frequency ultrasonic composite frequency is 35kHz / 35kHz, and the sound intensity is 0.5W / cm 2 , the action time is 10s, the intermittent time is 10s, and the extraction is stirred and extracted for 80min according to the above conditions. After stirring and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com