RDF (Refuse Derived Fuel) off-line burning technology and system

A combustion system, off-line technology, applied in clinker production, cement production, etc., can solve the problems of high water content, impermeable burning of refractory materials, affecting the quality of cement clinker, etc., to achieve safe and reliable processes and systems, and reduced size restrictions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

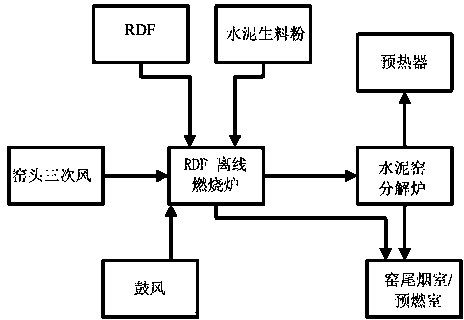

[0025] Such as figure 1 In the RDF off-line combustion process shown, an off-line combustion furnace for burning RDF is set outside the kiln line of the cement kiln calciner. , the tertiary air from the kiln head is passed into the offline combustion furnace to burn RDF at high temperature, and at the same time provide oxygen for the combustion of RDF; the centrifugal fan blows air from the bottom of the offline combustion furnace to keep RDF and raw meal powder in a suspended state; offline The exhaust gas generated by combustion in the combustion furnace enters the cement kiln calciner together with the low-density fly ash produced by the combustion of cement raw meal powder and RDF, and the high-density waste slag generated by the off-line combustion furnace enters the kiln tail smoke chamber together with the hot raw material and is calcined. clinker.

[0026] The combustion temperature in the off-line combustion furnace is 1000-1200°C.

[0027] An RDF off-line combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com