Method for preparing rebaudioside M through enzyme method

A technology for enzymatic preparation and rebaudioside, which is applied in the field of biological preparation of rebaudioside M, can solve problems such as no commercial production of rebaudioside M, and achieves shortening production cycle, expanding application scope, and producing The effect of cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

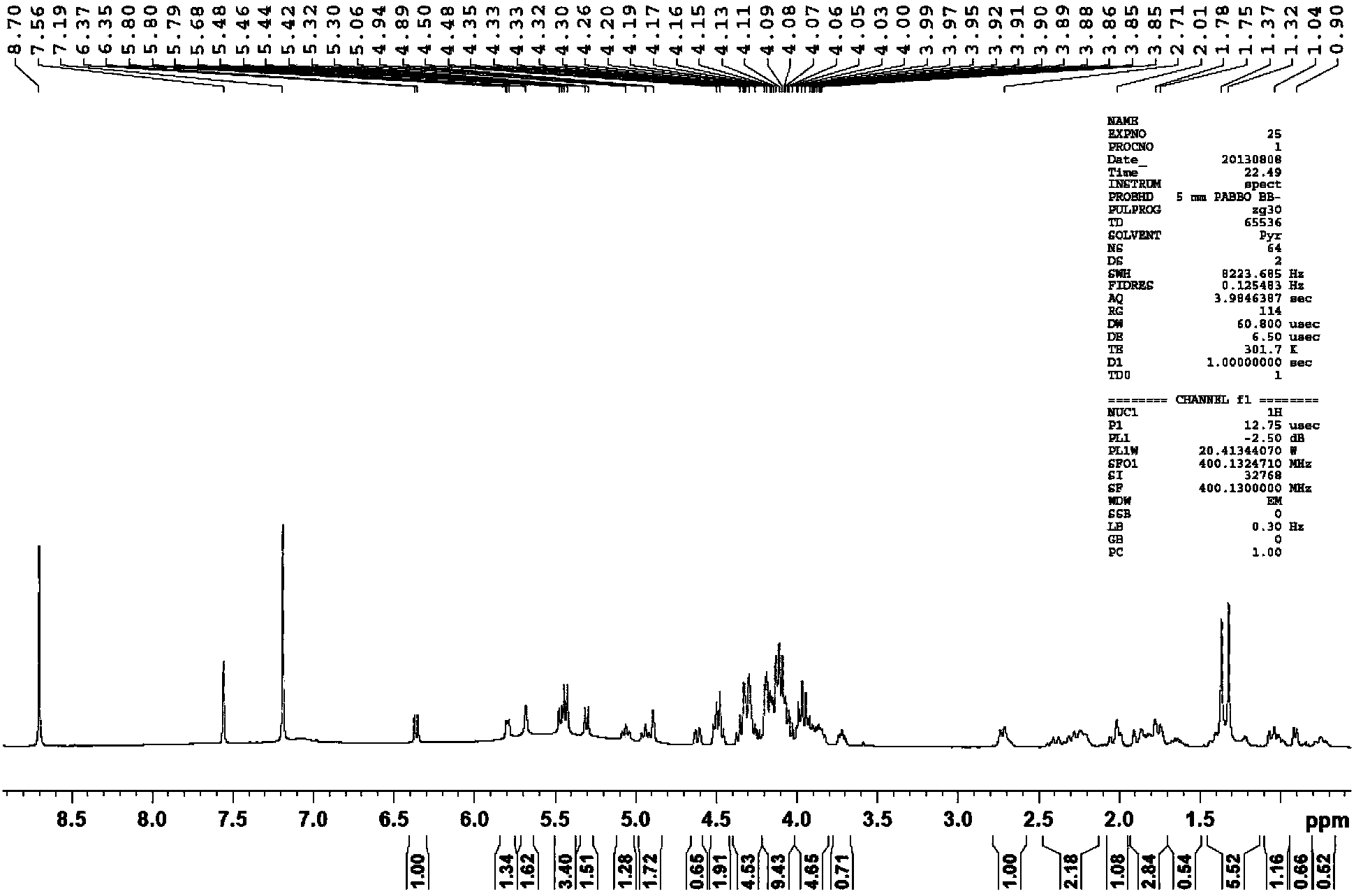

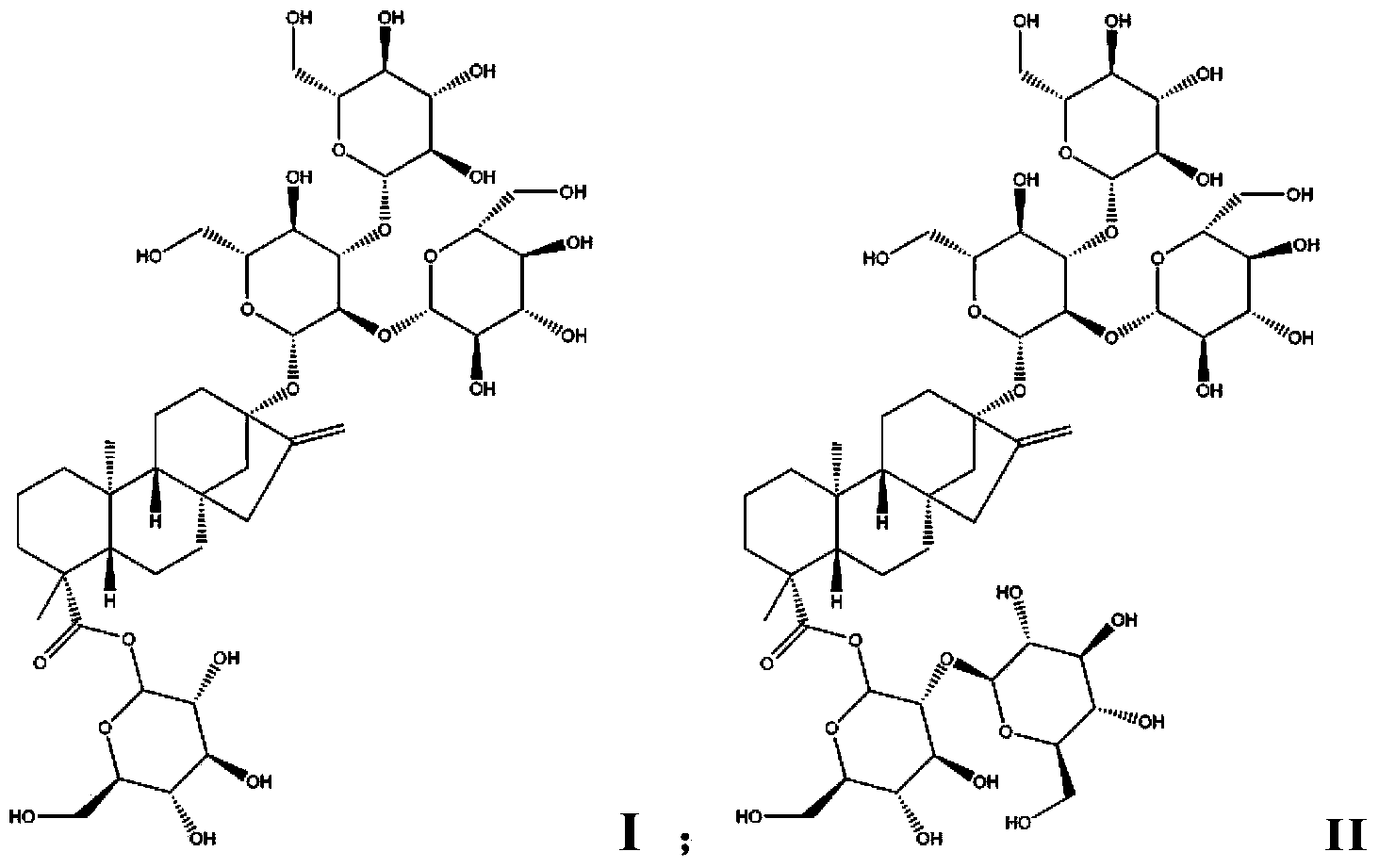

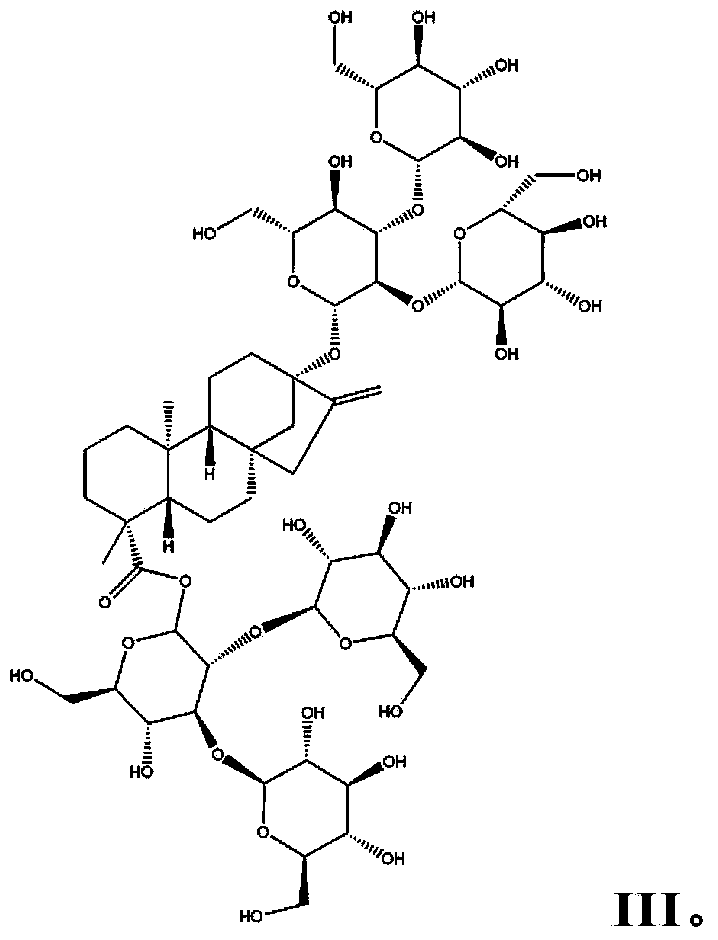

Image

Examples

Embodiment 1

[0045] Example 1: Preparation of recombinant Escherichia coli cells containing UGT-A

[0046]According to Sequence 1 and Sequence 2, the UGT-A gene fragment was synthesized, NdeI and BamHI restriction sites were added to both ends, and then connected into pUC57 vector (Suzhou Jinweizhi Biotechnology Co., Ltd.). The UGT gene fragment was digested with restriction endonucleases NdeI and BamHI, the purified fragment was recovered, and T4 ligase was added to connect the fragment into the corresponding restriction site of pET30a, and transformed into BL21 (DE3) strain.

[0047] Inoculate UGT strains into 4ml liquid LB medium with 1% ratio, shake culture at 37°C (200rpm) overnight, transfer overnight culture to 50ml liquid LB medium with 1% inoculum, shake culture at 37°C (200rpm) to OD 600 When the value reaches 0.6-0.8, add final concentration of 0.4mM IPTG and culture overnight at 20°C with shaking. After the induction, the cells were collected by centrifugation (8,000 rpm, 10 ...

Embodiment 2

[0048] Embodiment 2: Preparation of UGT-A freeze-dried powder

[0049] The recombinant cells of UGT-A prepared in Example 1 were ultrasonically disrupted in an ice bath, the disrupted solution was centrifuged (8,000 rpm, 10 min), and the supernatant was collected and freeze-dried for 24 hours to obtain a freeze-dried powder of UGT-A.

Embodiment 3

[0050] Embodiment 3: Prepare the recombinant escherichia coli cell containing UGT-B

[0051] According to Sequence 3 and Sequence 4, the UGT-B gene fragment was synthesized, NdeI and BamHI restriction sites were added to both ends, and it was connected into pUC57 vector (Suzhou Jinweizhi Biotechnology Co., Ltd.). The UGT gene fragment was digested with restriction endonucleases NdeI and BamHI, the purified fragment was recovered, and T4 ligase was added to connect the fragment into the corresponding restriction site of pET30a, and transformed into BL21 (DE3) strain.

[0052] Inoculate UGT strains into 4ml liquid LB medium with 1% ratio, shake culture at 37°C (200rpm) overnight, transfer overnight culture to 50ml liquid LB medium with 1% inoculum, shake culture at 37°C (200rpm) to OD 600 When the value reaches 0.6-0.8, add final concentration of 0.4mM IPTG and culture overnight at 20°C with shaking. After the induction, the cells were collected by centrifugation (8,000 rpm, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com