Multifunctional experiment device and method for deposition of zinc alloy coating

An experimental device and multi-functional technology, applied in metal material coating process, coating, sputtering plating, etc., can solve the problems of application limitations, long production cycle, missing plating, etc., and achieve good automatic control performance and short preparation cycle Effect of shortening and saving workshop space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

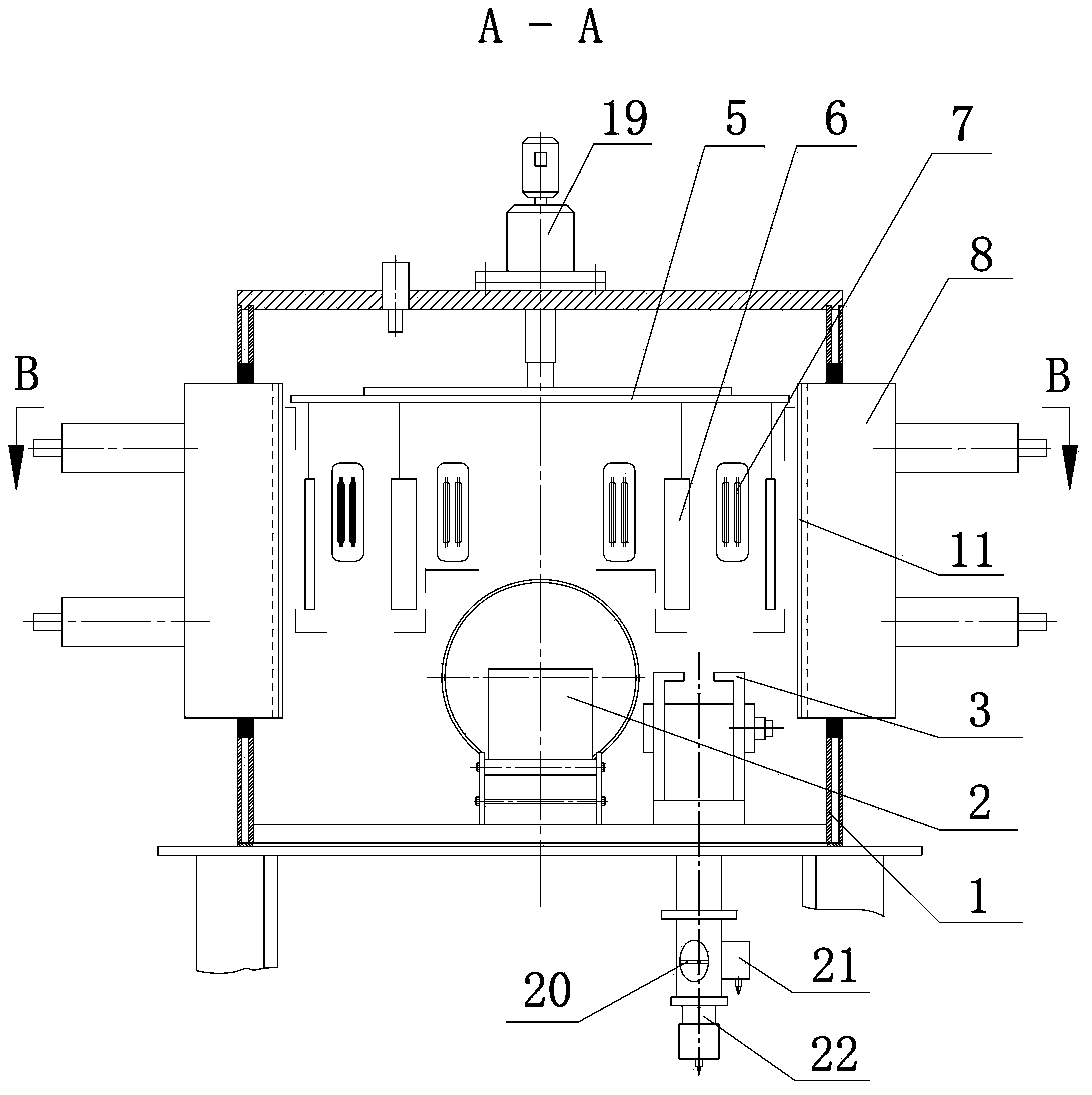

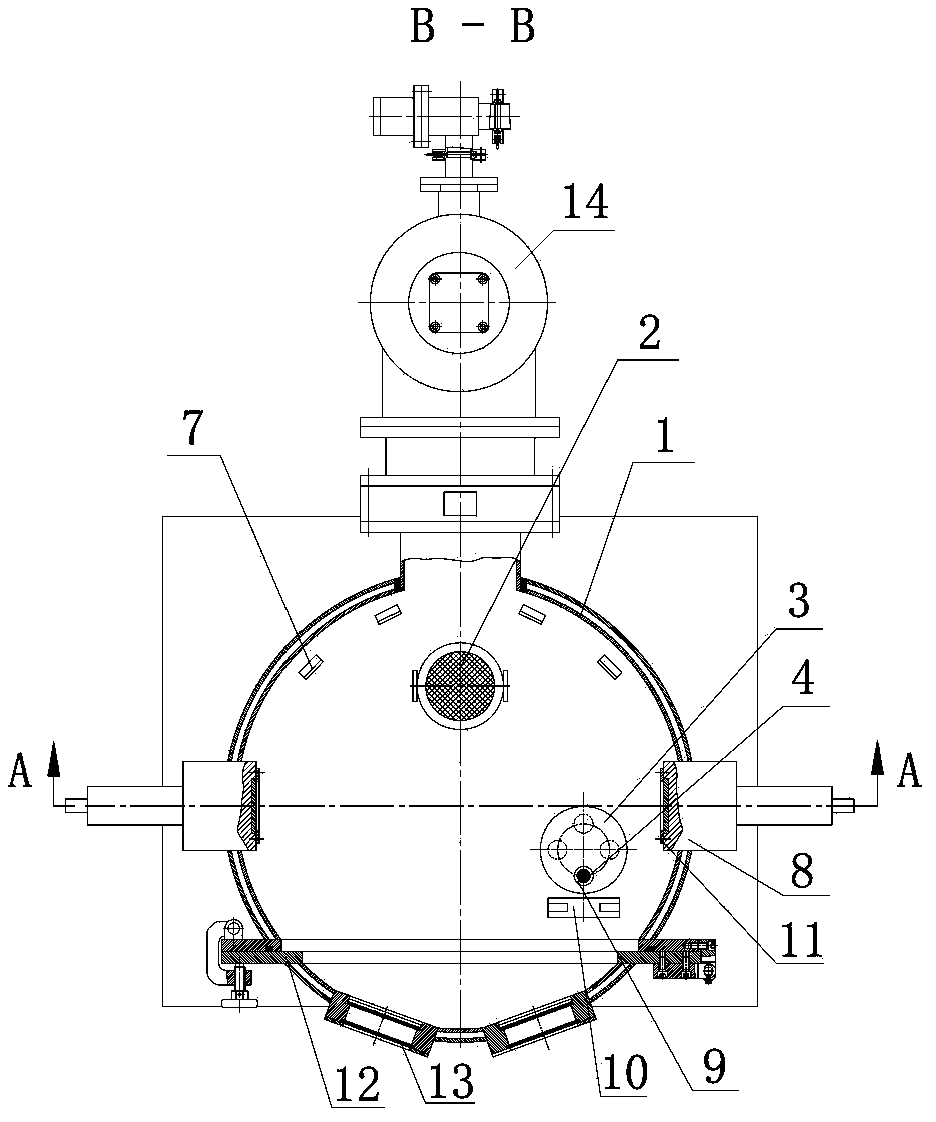

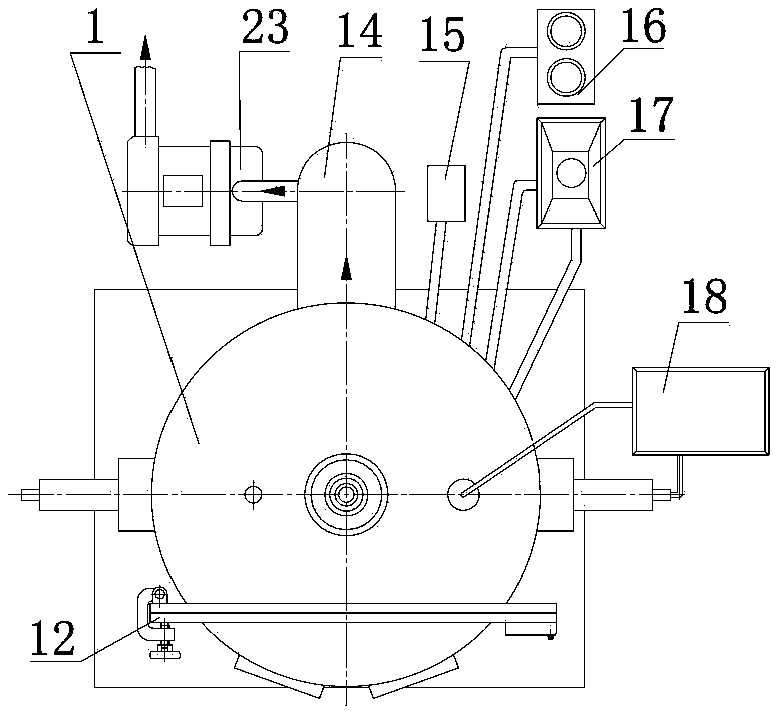

[0033] refer to Figure 1 to Figure 3 , a multifunctional experimental device for depositing a zinc alloy coating in this embodiment, an evaporation unit 3, a magnetron sputtering unit 8 and a heating unit 7 are integrated in a coating chamber; The above three functional components are set in the space. This embodiment adopts the integrated optimization design concept, and the above three different functional components are arranged in the same coating room 1. The coating room 1 is a double-layer circulating water cooling structure, and a double-layer water cooling structure is provided. The front door 12 is opened, and the front door is provided with an external peep hole 13; in this embodiment, the vapor deposition part 3 is arranged on one side of the bottom of the coating chamber 1, and the magnetron sputtering part 8 is arranged on the two side walls of the coating chamber 1, And a plurality of heating components 7 are arranged on the top of one side of the inner wall of ...

Embodiment 2

[0039] This embodiment is a multifunctional experimental device, which is integrated with an evaporation unit 3 , a magnetron sputtering unit 8 and a heating unit 7 . Metal magnesium with a thickness of about 550nm was deposited on the hot-dip galvanized substrate DC54D+Z (an ultra-deep-drawn hot-dip galvanized steel sheet) by DC magnetron sputtering, and vacuum diffusion annealing was performed at 350°C, and the holding time was 2min, 5min and 6min respectively. , to obtain zinc-magnesium alloy coated steel plate.

[0040] 1) Put the hot-dip galvanized substrate 6 through chemical cleaning to remove the grease or dirt on the surface, put it into the multi-functional coating chamber 1 and fix it on the substrate frame 5;

[0041] 2) Turn on the compressed air, circulate the cooling water, turn on the power, turn on the vacuum pump unit 23 to evacuate to 3x10 -3 Pa;

[0042] 3) Turn on the infrared radiation heating lamp 7 to heat the substrate 6, and bake and degas the subst...

Embodiment 3

[0049] 1) The hot-dip galvanized steel sheet is chemically cleaned and ultrasonically cleaned to remove grease and dirt on the surface, put into the plating chamber 1 and fixed on the substrate frame 5;

[0050] 2) Turn on the circulating cooling water, turn on the power supply, and turn on the vacuum pump unit 23 to evacuate to 3x10- 3 Pa;

[0051] 3) Turn on the infrared radiation heating lamp 7, and heat the substrate 6 at 150°C for baking and degassing; use the Kaufman ion source 2 to clean the surface of the substrate 6 for (10-15) minutes, and the working vacuum of the Kaufman ion source (0.01-0.03) Pa;

[0052]4) Put cylindrical aluminum particles with a diameter of 3mm and a height of 3mm in the crucible 9 of the electron gun, so that the acceleration current is not greater than 20mA, the electron beam current is (1.2-2) times the ion beam current, and the value of the screen electrode voltage is ( 200-300) V, adjust the size of the electron beam spot, observe from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com