Aluminum-silicon alloy surface ceramic treatment method and apparatus

The technology of aluminum-silicon alloy and processing equipment is applied in the field of micro-arc oxidation processing equipment on the surface of aluminum-silicon alloy, which can solve the problems of inability to achieve heat resistance, heat insulation, wear resistance, low degree of automation control, slow film forming speed, etc. To achieve the effect of ensuring personal safety of electricity users, reducing floor space and neat layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

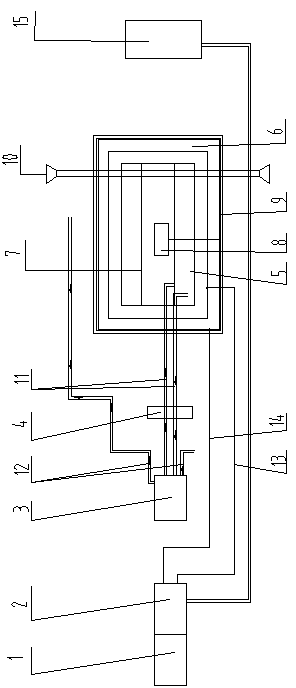

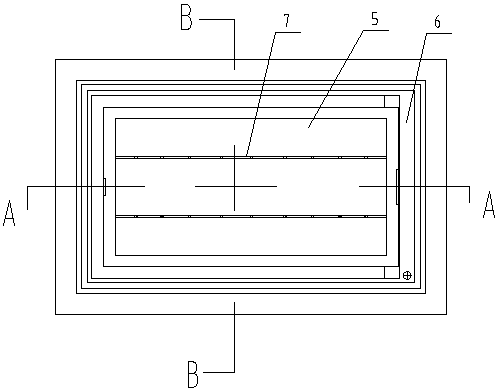

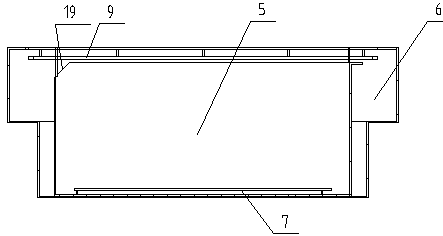

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings, as shown in the figure: a kind of aluminum-silicon alloy surface ceramic treatment equipment of the present invention includes a stainless steel cathode tank 5, a double-layer PVC liquid storage tank 6, and in this liquid storage tank 6 A copper plate anode 9 is arranged around the surface, wherein the stainless steel cathode tank 5 and the liquid storage tank 6 are combined together and can be separated. The stainless steel cathode tank 5 is easy to lift and clean with a simple row crane 10, which greatly reduces the floor space and saves energy. The electrolyte is added, which makes the layout of the production workshop more orderly and facilitates standardized production and management. Cathode tank wall 17 is made of stainless steel, also serves as cathode; Stainless steel cathode tank 5 one end is lower, is provided with overflow port 19, and its height is equal to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap