Silicon-based composite material, its preparation method and its application

A silicon-based composite material, silicate technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as lattice structure collapse, cell cycle performance, rate performance deterioration, and increased cell internal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

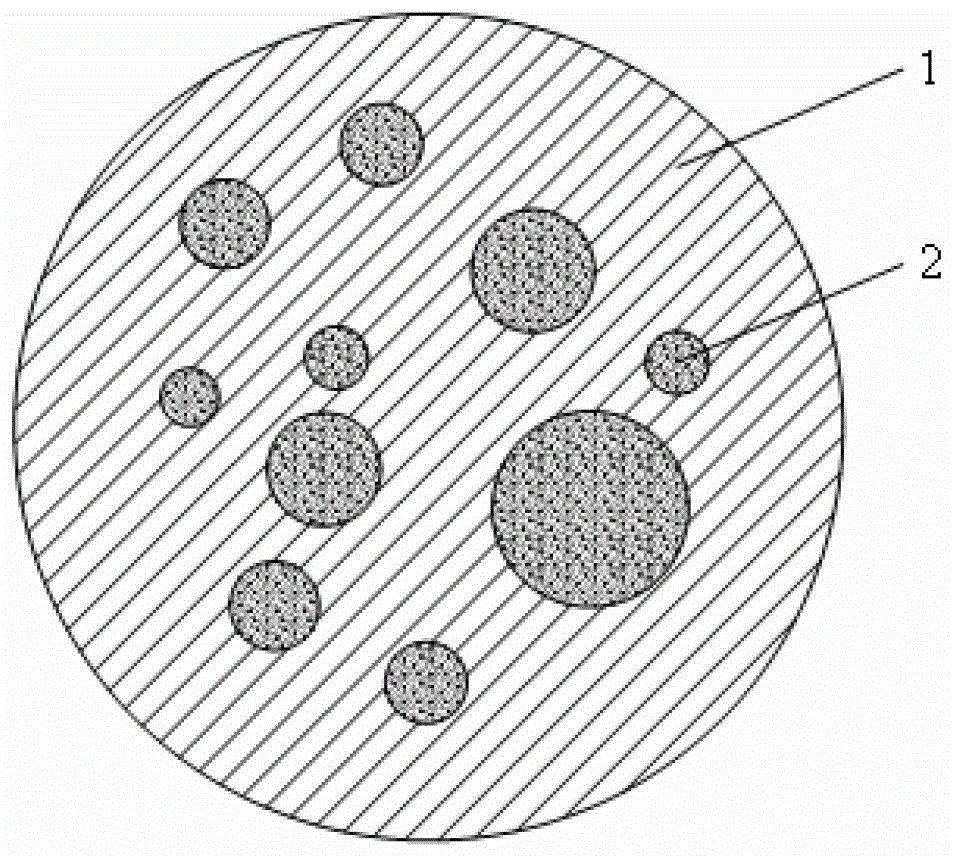

[0030] The method for preparing a silicon-based composite material according to the second aspect of the present invention, which prepares the silicon-based composite material according to the first aspect of the present invention, includes the following steps: dispersing silicon particles into absolute ethanol and / or deionized water to form Suspension; disperse the silicate and optional carbon in absolute ethanol and / or deionized water to form a suspension; ultrasonically shake the two suspensions separately and then stir at room temperature; add the silicon particle suspension dropwise Silicate and optionally carbon in suspension to form a mixture which is heated and stirred until the mixture evaporates into a paste; the paste is dried in an oven to obtain a lump , and then grind and sieve the block to obtain granular undersize; heat-treat the granular undersize in an inert atmosphere, and then grind and sieve to obtain silicon particles, silicates, and optional carbon. Sili...

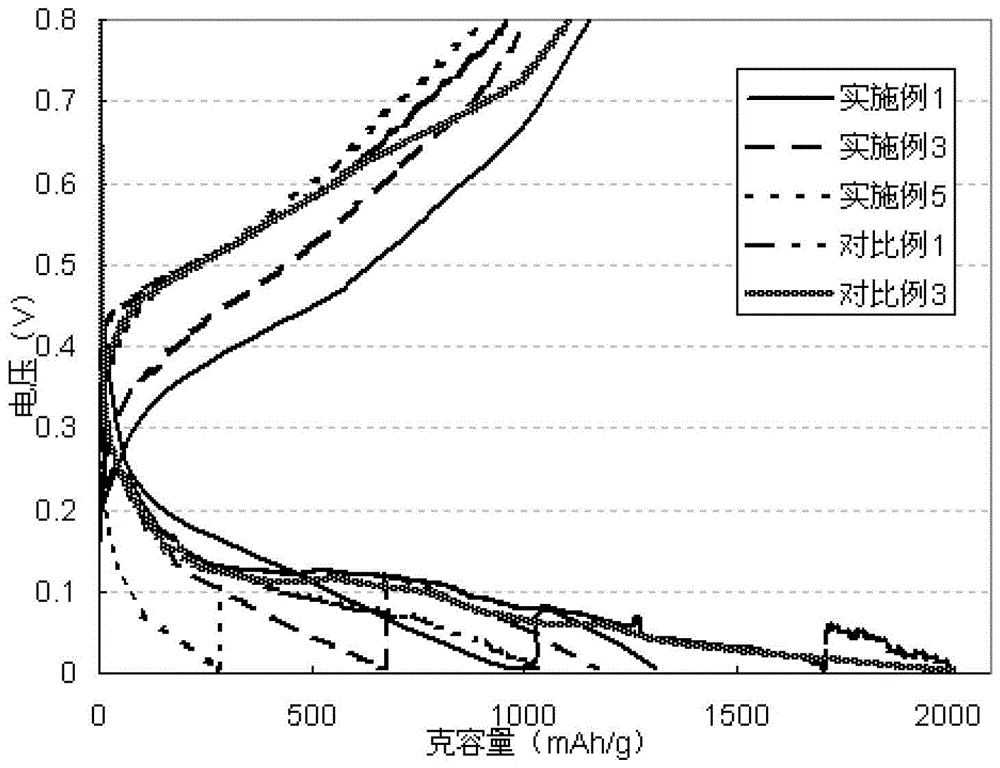

Embodiment 1

[0041] Disperse 2.4g of silicon particles in 80g of deionized water to form a suspension, wherein the mass ratio of silicon particles to deionized water is 3.0%:1;

[0042] 1.4gLi 2 SiO 3 and 0.2g acetylene black (a kind of carbon (C)) are dispersed in 100g deionized water to form a suspension, wherein Li 2 SiO 3 , The mass ratio of acetylene black to deionized water is 1.4%:0.2%:1;

[0043] The above two suspensions were ultrasonically oscillated for 30 min and then stirred at room temperature for 5 h;

[0044] The suspension of silicon particles was added dropwise to the Li 2 SiO 3 / C suspension, form a mixed solution, and stir at 40°C at the same time, add dropwise and stir for 6 hours, until the mixed solution evaporates into a paste;

[0045] Drying the paste in an oven at 60°C to obtain lumps, and then grinding and sieving the lumps to obtain granular undersize;

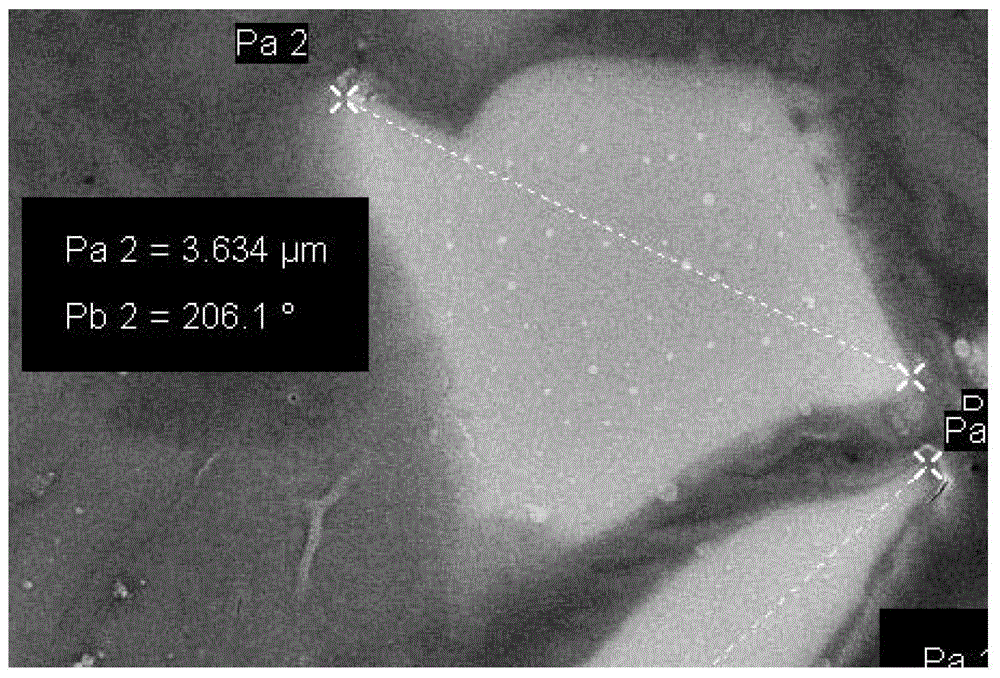

[0046] The granular undersize was heat-treated at 400 °C for 6 h in an argon atmosphere, and then the...

Embodiment 2

[0048] Disperse 2.0g of silicon particles in 2000g of absolute ethanol to form a suspension, the mass ratio of silicon particles to absolute ethanol is 0.1%:1;

[0049] 1.6gLi 8 SiO 6 and 0.4g of graphite (a kind of carbon (C)) are dispersed in 2000g of absolute ethanol to form a suspension, wherein Li 8 SiO 6 , The mass ratio of graphite and absolute ethanol is 0.08%:0.02%:1;

[0050] The above two suspensions were ultrasonically oscillated for 10 min and then stirred at room temperature for 5 h;

[0051] The suspension of silicon particles was added dropwise to the Li 8 SiO 6 / C suspension, form a mixed solution, while stirring at 25°C, add dropwise and stir for 10 hours, until the mixed solution evaporates into a paste;

[0052] Drying the paste in an oven at 60°C to obtain lumps, and then grinding and sieving the lumps to obtain granular undersize;

[0053] The granular undersize was heat-treated at 500 °C for 5 hours in an argon atmosphere, and then the heat-treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com