Preparation of high-selectivity inorganic skeletal biomimic TiO2 photocatalyst by sol-hydrothermal method at low temperature

A high-selectivity, photocatalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, water/sewage treatment, etc., can solve the problem of molecular recognition site damage, low adsorption efficiency, and unfavorable target organic pollutant selection Sexual photocatalysis and other problems, to achieve high mechanical strength, not easy to damage, good selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

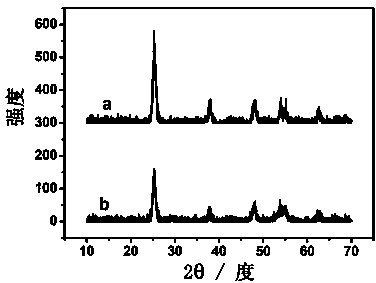

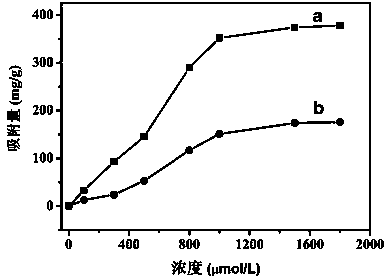

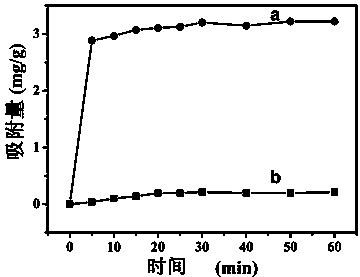

[0022] Add 0.4 g of 4-nitrophenol, 20 mL of anhydrous tetra-n-butyl titanate, 26 mL of absolute ethanol and 4 mL of glacial acetic acid into beaker A. In addition, mix 12 mL of absolute ethanol, 12 mL of glacial acetic acid and 8 mL of water evenly, and this mixture is called liquid B. Slowly drop liquid B into liquid A, stir the solution at room temperature for 3 hours, then transfer to a polytetrafluoroethylene-lined reactor and conduct a hydrothermal reaction at 140°C for 12 hours to obtain a light yellow solid. The solid product was washed three times with ethanol and deionized water respectively, and then the mixture of methanol:ammonia water (volume ratio 1:1) was used as the eluent, and the template molecules were removed by Soxhlet extraction to obtain the white inorganic skeleton biomimetic TiO 2 catalyst of light. Such as figure 1 , 2 , 3, and 4, the inorganic framework biomimetic TiO prepared by the present invention 2 Photocatalysts have good selectivity and hi...

Embodiment 2

[0024]Add 0.4 g of 2-nitrophenol, 20 mL of anhydrous tetra-n-butyl titanate, 26 mL of absolute ethanol and 4 mL of glacial acetic acid into beaker A. In addition, mix 12 mL of absolute ethanol, 12 mL of glacial acetic acid and 8 mL of water evenly, and this mixture is called liquid B. Slowly drop liquid B into liquid A, stir the solution at room temperature for 3 hours, then transfer to a polytetrafluoroethylene-lined reactor and conduct a hydrothermal reaction at 140°C for 12 hours to obtain a light yellow solid. The solid product was washed three times with ethanol and deionized water respectively, and then the mixture of methanol:ammonia water (volume ratio 1:1) was used as the eluent, and the template molecules were removed by Soxhlet extraction to obtain the white inorganic skeleton biomimetic TiO 2 catalyst of light.

Embodiment 3

[0026] Add 0.79 g of 4-nitrophenol, 20 mL of anhydrous tetra-n-butyl titanate, 26 mL of absolute ethanol and 4 mL of glacial acetic acid into beaker A. In addition, mix 12 mL of absolute ethanol, 12 mL of glacial acetic acid and 8 mL of water evenly, and this mixture is called liquid B. Slowly drop liquid B into liquid A, stir the solution at room temperature for 3 hours, then transfer to a polytetrafluoroethylene-lined reactor and conduct a hydrothermal reaction at 140°C for 12 hours to obtain a light yellow solid. The solid product was washed three times with ethanol and deionized water respectively, and then the mixture of methanol:ammonia water (volume ratio 1:1) was used as the eluent, and the template molecules were removed by Soxhlet extraction to obtain the white inorganic skeleton biomimetic TiO 2 catalyst of light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com