Golden low-emissivity coated glass and manufacturing method thereof

A low-emission coating, glass technology, applied in chemical instruments and methods, glass/slag layered products, metal layered products, etc. The product cannot obtain the golden appearance and other problems, and achieves excellent shading performance, pure appearance and color, and good energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

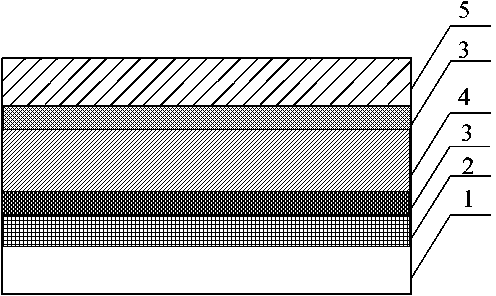

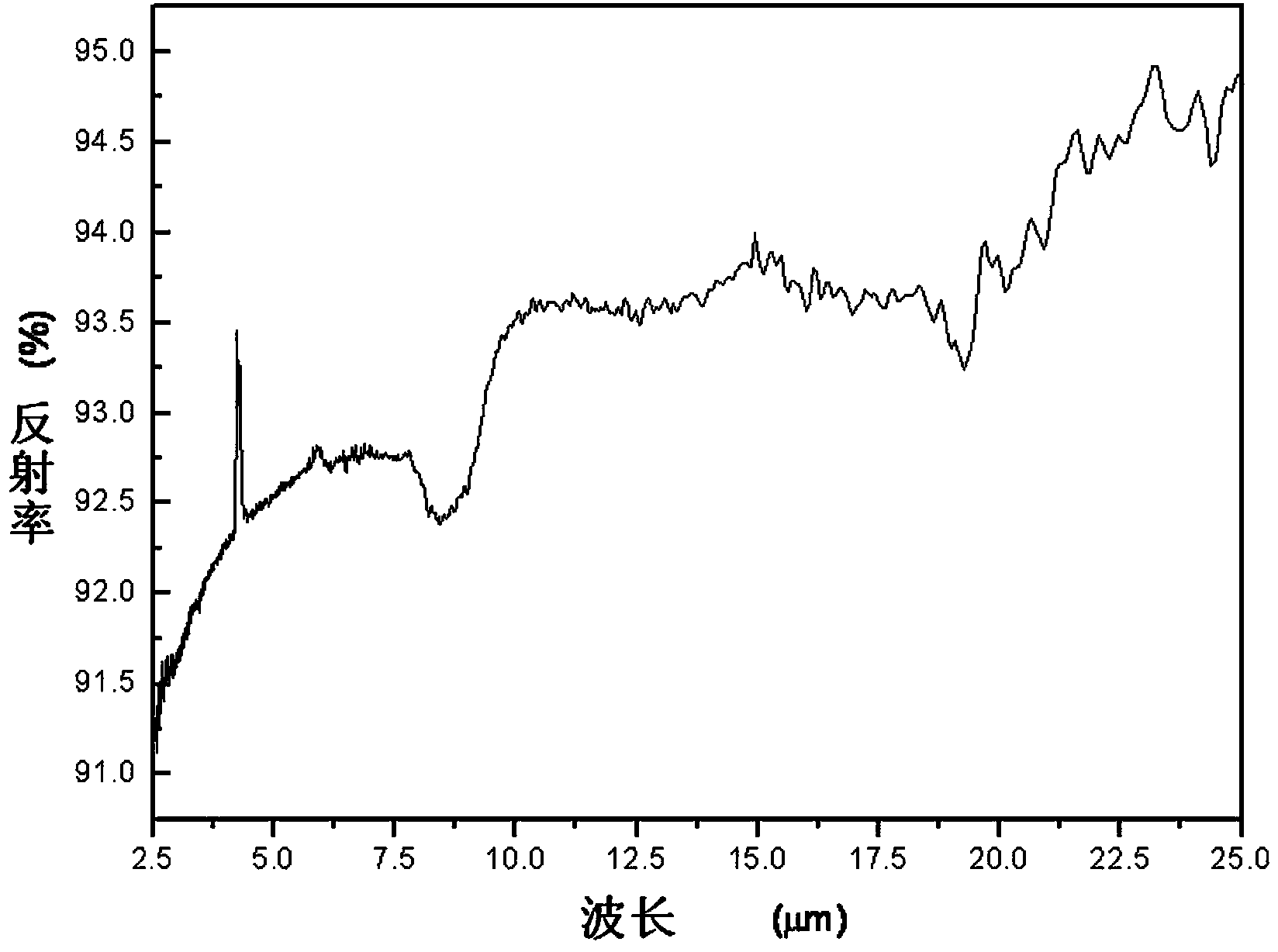

[0044] A golden low-emissivity coated glass, which deposits the following films sequentially on the surface of a glass substrate: a silicon nitride buffer layer film, a nickel-chromium alloy induction layer film, a gold functional layer film, a nickel-chromium alloy induction layer film, a ZnO:Al protective layer, According to the order of deposition, the thicknesses of the film structures of each layer are as follows: the thickness of the silicon nitride buffer layer is 21nm, the thickness of the nickel-chromium alloy induction layer is 3nm, the thickness of the gold functional layer is 40nm, the second nickel-chromium alloy induction layer The thickness of the ZnO:Al protective layer is 3nm, the thickness of the ZnO:Al protective layer is 12nm, and the glass substrate adopts float glass.

[0045] A method for manufacturing golden low-emissivity coated glass as described above, characterized in that it comprises the following steps:

[0046] Step 1: Substrate pretreatment...

Embodiment 2

[0064] A golden low-emissivity coated glass, which deposits the following films sequentially on the surface of a glass substrate: a silicon nitride buffer layer film, a nickel-chromium alloy induction layer film, a gold functional layer film, a nickel-chromium alloy induction layer film, a ZnO:Al protective layer, According to the order of deposition, the thicknesses of the film structures of each layer are as follows: the thickness of the silicon nitride buffer layer is 22nm, the thickness of the nickel-chromium alloy induction layer is 3.5nm, the thickness of the gold functional layer is 45nm, and the thickness of the second nickel-chromium alloy induction layer is 45nm. The thickness of the layer is 3.5nm, the thickness of the ZnO:Al protective layer is 13nm, and the glass substrate adopts float glass.

[0065] A method for manufacturing golden low-emissivity coated glass as described above, characterized in that it comprises the following steps:

[0066] Step 1: Substr...

Embodiment 3

[0084] A golden low-emissivity coated glass, which deposits the following films sequentially on the surface of a glass substrate: a silicon nitride buffer layer film, a nickel-chromium alloy induction layer film, a gold functional layer film, a nickel-chromium alloy induction layer film, a ZnO:Al protective layer, According to the order of deposition, the thicknesses of the film structures of each layer are as follows: the thickness of the silicon nitride buffer layer is 23nm, the thickness of the nickel-chromium alloy induction layer is 4nm, the thickness of the gold functional layer is 42nm, the second nickel-chromium alloy induction layer The thickness of the ZnO:Al protective layer is 4nm, the thickness of the ZnO:Al protective layer is 14nm, and the glass substrate adopts float glass.

[0085] A method for manufacturing golden low-emissivity coated glass as described above, characterized in that it comprises the following steps:

[0086] Step 1: Substrate pretreatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com