System and method for preparing hydrogen and oxygen by electrolyzing sewage

A technology of electrolyzing sewage and hydrogen, which is applied in the field of hydrogen and oxygen production systems, can solve the problems of consuming large groundwater resources, low cost of hydrogen production, high manufacturing cost, etc., and achieves the goal of reducing dust emissions, large reserves, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

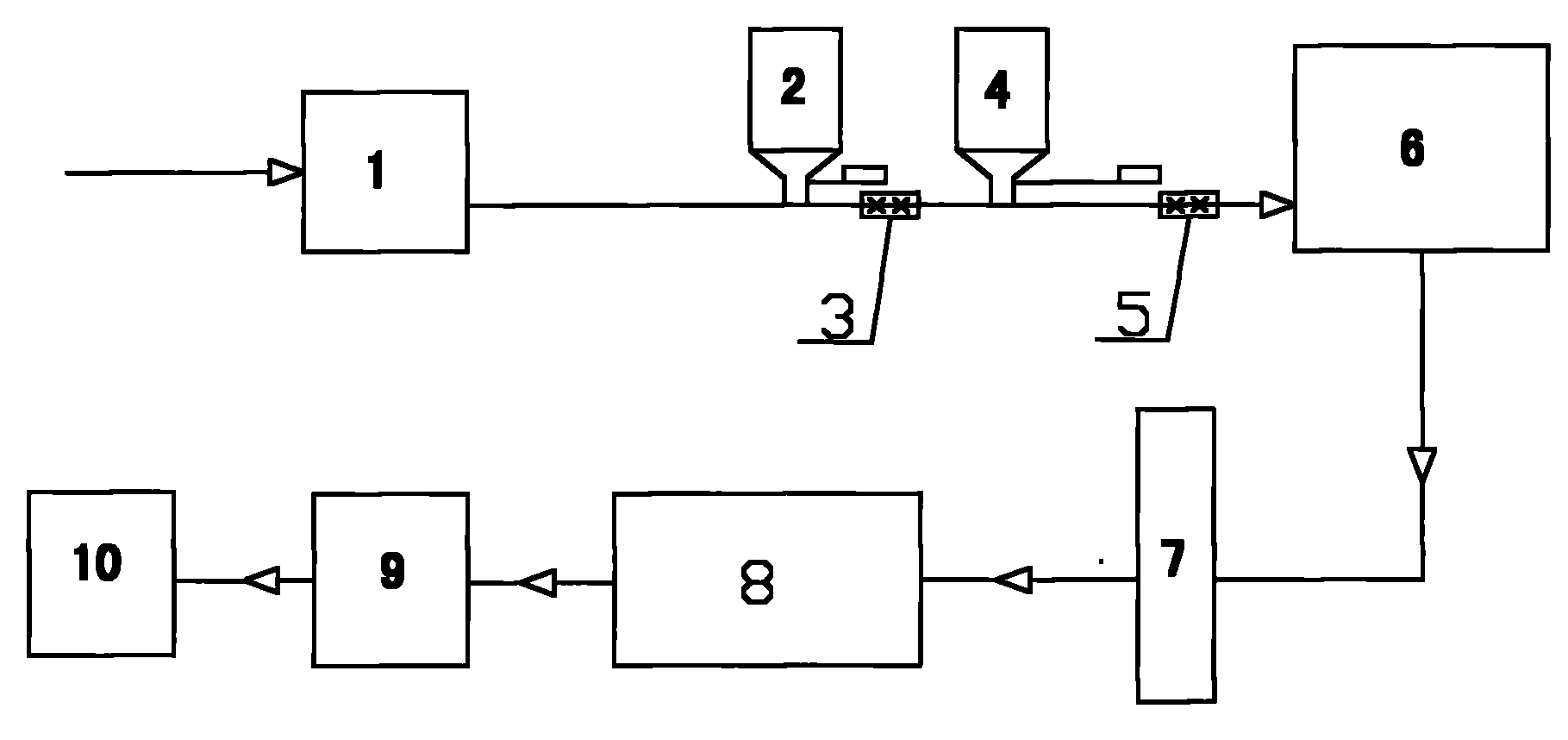

[0022] Embodiment 1: A system for producing hydrogen and oxygen by electrolyzing sewage, which includes a primary sedimentation tank 1, agent A dosing device 2, agent A self-leveling mixer 3, agent B dosing device 4, and agent B self-leveling mixer 5 , secondary sedimentation tank 6, resin filter 7, RO reverse osmosis water purifier 8, pure water storage tank 9 and electrolytic water device 10, primary sedimentation tank 1 is connected with the water inlet pipeline of agent A self-leveling mixer 3, and connected The pipeline at the water inlet of agent A self-leveling mixer 3 is equipped with agent A dosing device 2, the outlet of agent A self-leveling mixer 3 is connected to the water inlet pipeline of agent B self-leveling mixer 5, and connected to the water inlet of agent B self-leveling mixer 5 The pipeline at the place is provided with B agent dosing device 4, and the water outlet of B agent self-leveling mixer 5 is connected with the secondary sedimentation tank 6 pipelin...

Embodiment 2

[0023] Embodiment 2: A method for producing hydrogen and oxygen by electrolysis of sewage, which includes the following steps: (1) primary precipitation of sewage; (2) adding agent A and agent B to the sewage after primary precipitation; (3) sewage Secondary precipitation; (4) Filtration by resin filter; (5) Pure water is obtained by RO reverse osmosis water purification mechanism; (6) Hydrogen and oxygen are produced by electrolysis of pure water;

[0024] (1) Primary sedimentation of sewage: discharge the sewage into the primary sedimentation tank 1 and let it stand still, so that the silt, large granular dirt and various floating objects in the sewage are deposited at the bottom of the primary sedimentation tank 1;

[0025] (2) Add agent A and agent B to the sewage after the primary precipitation: when the sewage after the primary precipitation flows through the pipeline connecting the primary sedimentation tank 1 and the secondary sedimentation tank 6, the agent A dosing de...

Embodiment 3

[0032] Embodiment 3: A method for producing hydrogen and oxygen by electrolysis of sewage, which includes the following steps: (1) primary precipitation of sewage; (2) adding agent A and agent B to the sewage after primary precipitation; (3) sewage Secondary precipitation; (4) Filtration by resin filter; (5) Pure water is obtained by RO reverse osmosis water purification mechanism; (6) Hydrogen and oxygen are produced by electrolysis of pure water;

[0033] (1) Primary sedimentation of sewage: discharge the sewage into the primary sedimentation tank 1 and let it stand still, so that the silt, large granular dirt and various floating objects in the sewage are deposited at the bottom of the primary sedimentation tank 1;

[0034] (2) Add agent A and agent B to the sewage after the primary precipitation: when the sewage after the primary precipitation flows through the pipeline connecting the primary sedimentation tank 1 and the secondary sedimentation tank 6, the agent A dosing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com