Preparation method for dedicated soybean paste leavening agent

A technology of starter and soy sauce, which is applied in the field of preparation of special starter for soy sauce, can solve the problems of miscellaneous strains, incomplete enzyme system, and difficulty in product quality assurance, and achieve shortened fermentation time, simple production process, and safe product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

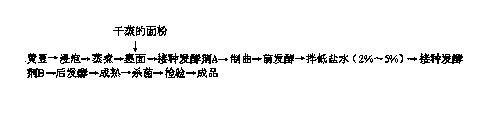

Method used

Image

Examples

Embodiment 1

[0010] Starter A: medium components ( w / w ), 90% soybean meal powder, 10% bran, 60% moisture adjustment, 0.1MPa damp heat sterilization for 30 minutes, inoculated with Aspergillus oryzae, Aspergillus niger and Bacillus natto respectively, the inoculation amount was 4.0% ( v / w ), ratio control 2:1:1, cultured at 30°C for 72 hours, after spores are produced or spores are formed, they are dried at low temperature (such as freeze-dried), inspected, aseptically measured and packaged, and finished.

[0011] Starter B: medium components ( w / w ), 10° wort, sterilized at 0.075MPa for 20min, inoculated with ester-producing yeast, the inoculum amount was 1.0% ( v / v ), cultured at 28°C for 24 hours, after the culture was completed, the cells were collected by centrifugation, dried at low temperature (such as freeze-dried), inspected, sterile measured and packaged, and the finished product.

Embodiment 2

[0013] Starter A: medium components ( w / w ), 80% soybean meal powder, 20% bran, 70% moisture adjustment, 0.1MPa damp heat sterilization for 30min, inoculated with Aspergillus oryzae, Aspergillus niger and Bacillus natto respectively, the inoculation amount was 3.0% ( v / w ), ratio control 1:1:1, cultured at 32°C for 60 h, after spores are produced or spores are formed, they are dried at low temperature (such as freeze-dried), inspected, sterile measured and packaged, and finished.

[0014] Starter B: medium components ( w / w ), 8° wort, sterilized at 0.075MPa for 20min, inoculated with ester-producing yeast, the inoculum amount was 0.8% ( v / v ), cultured at 28°C for 30 hours, and after the culture was completed, the bacteria were collected by centrifugation, dried at low temperature (such as freeze-dried), inspected, sterile measured and packaged, and finished.

Embodiment 3

[0016] Starter A: medium components ( w / w ), 70% soybean meal powder, 30% bran, 50% moisture adjustment, 0.1MPa damp heat sterilization for 30min, inoculated with Aspergillus oryzae, Aspergillus niger and Bacillus natto respectively, the inoculation amount was 2.0% ( v / w ), the ratio is controlled at 1:2:1, cultured at 35°C for 48 hours, and after spores are produced or spores are formed, they are dried at low temperature (such as freeze-dried), inspected, sterile measured and packaged, and finished.

[0017] Starter B: medium components ( w / w ), 12° wort, sterilized at 0.075MPa for 20min, inoculated with ester-producing yeast, the inoculum amount was 1.5% ( v / v ), cultured at 28°C for 24 hours, after the culture was completed, the cells were collected by centrifugation, dried at low temperature (such as freeze-dried), inspected, sterile measured and packaged, and the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com