Flue gas mercury sampling gun for thermal power plant

A thermal power plant and sampling gun technology, applied in the field of mercury sampling equipment and thermal power plant flue gas mercury sampling gun, can solve the problems of large overall error, high risk, high price, etc., and achieve good sealing and heat resistance. , The effect of reducing on-site operation steps and reducing sampling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

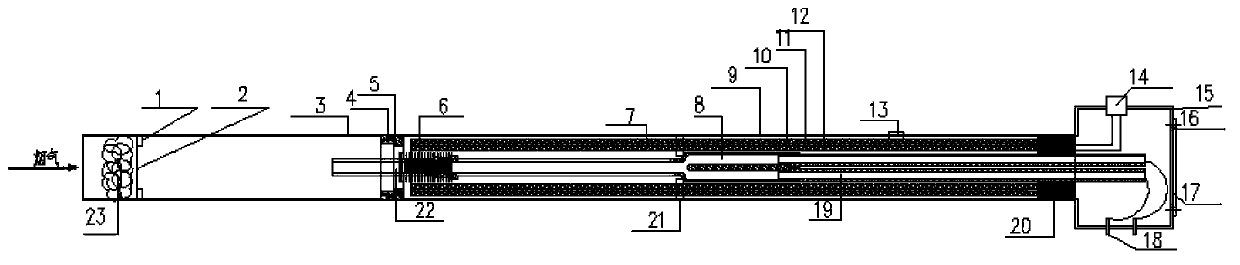

[0025] see figure 1 , the present invention includes a front non-heating probe tube 3, a sampling gun body and a stainless steel shell 15 with an end cover flange 17.

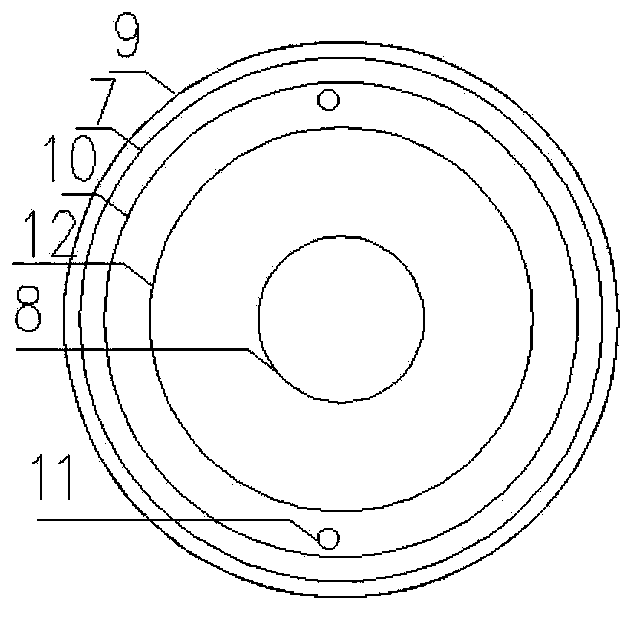

[0026] The main body of the sampling gun includes a stainless steel sleeve 9, an inner ceramic tissue paper 7, a heating layer, an outer ceramic sleeve 10, and a quartz tube; the front end of the stainless steel sleeve 9 is detachably connected to the front non-heating probe 3; specifically Yes, the front end of the stainless steel sleeve 9 is connected to the front non-heating probe 3 through a flange 22, and the connection between the front end of the stainless steel sleeve 9 and the front non-heating probe 3 is provided with a copper O-ring for sealing 5 and PTFE sealing ring 4. This connection method that connects the front non-heating probe tube 3 and the outer stainless steel casing 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com