Optical polarization converter and manufacturing method thereof

A manufacturing method and converter technology, applied in the field of electronics, can solve the problems of increasing device insertion loss, complex technical process, complex component components, etc., and achieve the effects of simple structure, simple manufacturing process and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

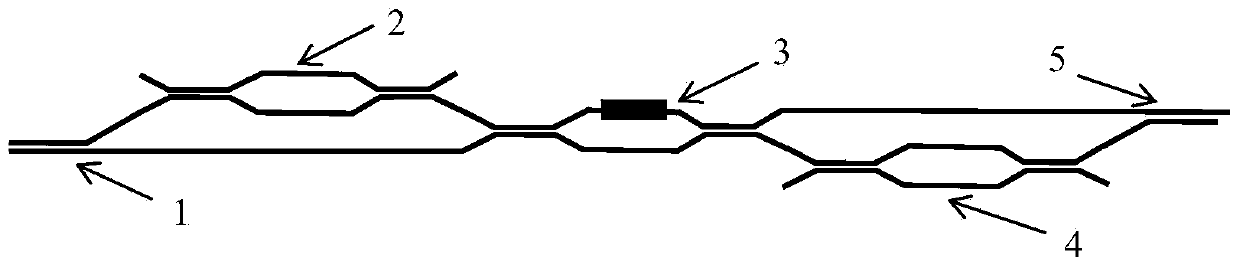

[0035] Refer to attached figure 1 , the optical polarization converter of the present invention includes a three-dimensional 2×2 polarization beam splitter 1, a first half-wave plate 2, an adjustable coupler and a phase shifter made of silicon-based silicon dioxide materials. The combined device 3, the second half-wave plate 4, and the polarization beam combiner 5.

[0036] The polarization beam splitter 1 is located at the leftmost end of the optical polarization converter, and the incident light of any polarization state is decomposed into two beams of linearly polarized light whose polarization directions have an included angle of 90° through the polarization beam splitter 1 .

[0037] The first half-wave plate 2 is connected to the polarization beam splitter 1 through an optical waveguide, and any one of the two beams of linearly polarized light output from the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com