Dye-sensitized solar cell

A technology for solar cells and dye sensitization, applied in the field of dye-sensitized solar cells, can solve the problems of low photoelectric conversion efficiency of dye-sensitized solar cells, and achieve the effects of high repeatability, inhibition of electron recombination, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

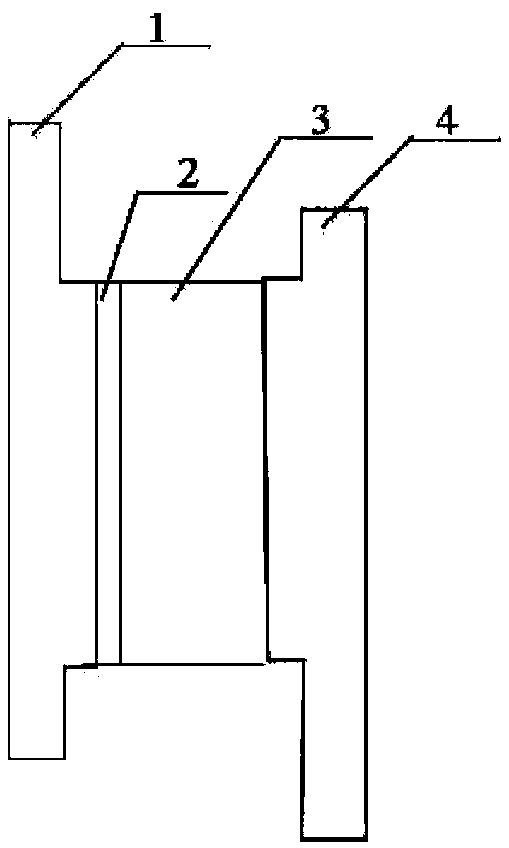

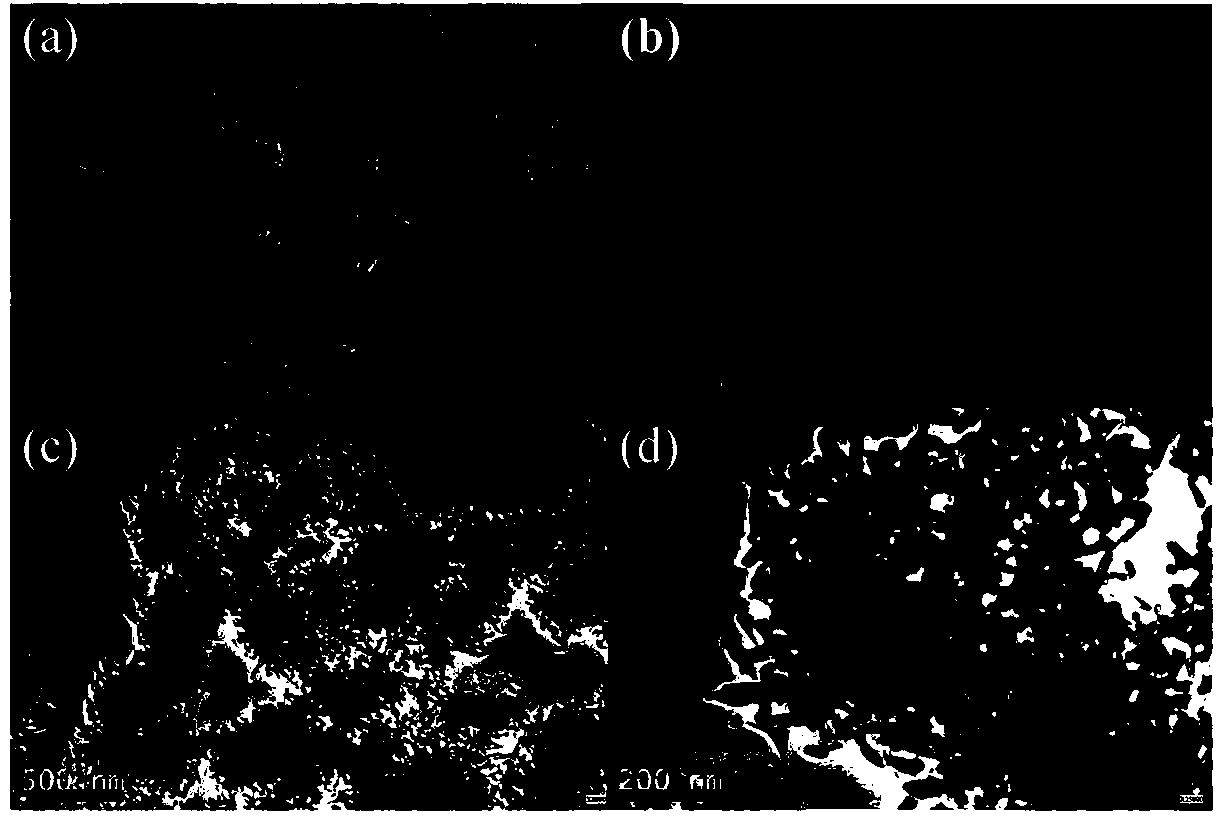

[0039] This embodiment prepares untreated SnO as follows 2 nano film

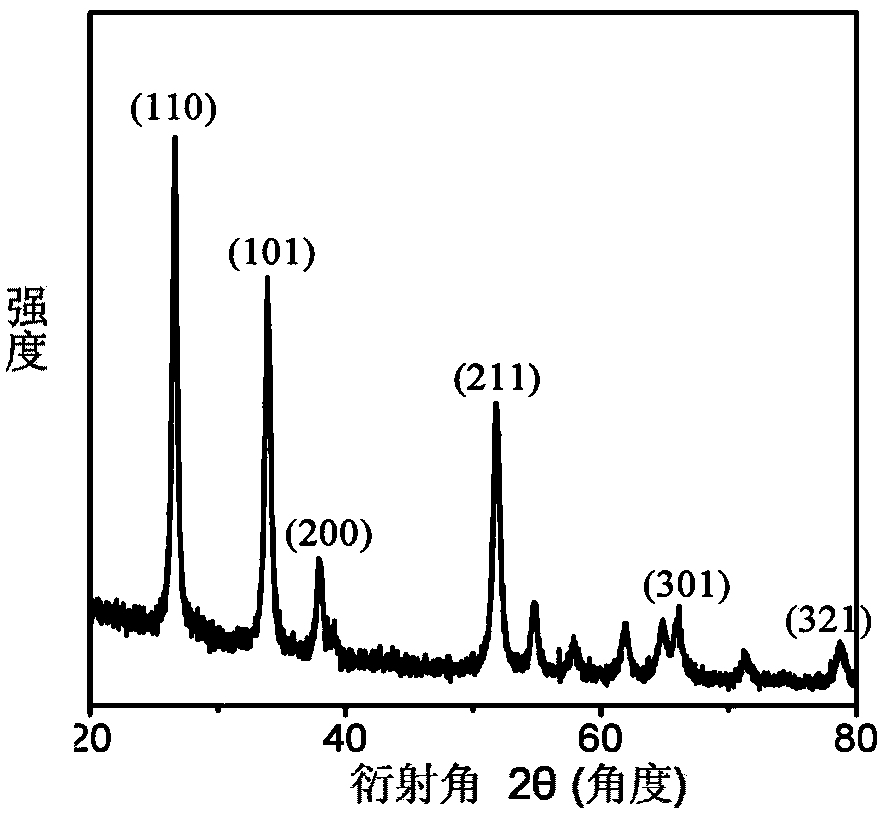

[0040] a. Preparation of SnO 2 powder:

[0041] a1, the deionized water of 90ml is mixed with the absolute ethanol of 10ml, and the sodium citrate dihydrate of 1.2g tin sulfate and 4.5g is added therein to obtain mixed solution X;

[0042] a2. Put the mixed solution X into the reaction kettle and heat it to the reaction temperature of 160°C, and maintain the reaction temperature for 12 hours under normal pressure. After the reaction is completed, the temperature in the reaction kettle is naturally cooled to room temperature, and the powder is obtained as the lower layer. The above supernatant is the layered substance of the upper layer, and the supernatant is sucked out;

[0043] a3. Centrifuge and wash the powder with deionized water and absolute ethanol in sequence, then put the cleaned powder into a drying oven and dry at 70°C for 2 hours to obtain a dry powder;

[0044] a4. Calcining the dry powder ...

Embodiment 2

[0055] This example prepares SnO doped with saponite as follows 2 Nano film:

[0056] a. Preparation of SnO 2 powder:

[0057] a1, the deionized water of 90ml is mixed with the absolute ethanol of 10ml, and the sodium citrate dihydrate of 1.2g tin sulfate and 4.5g is added therein to obtain mixed solution X;

[0058] a2. Put the mixed solution X into the reaction kettle and heat it to the reaction temperature of 160°C, and maintain the reaction temperature for 12 hours under normal pressure. After the reaction is completed, the temperature in the high-pressure reaction kettle is naturally cooled to room temperature, and the powder is obtained as the lower layer. , The above supernatant is the layered substance of the upper layer, and the supernatant is sucked out;

[0059] a3. Centrifuge and wash the powder with deionized water and absolute ethanol in sequence, then put the cleaned powder into a drying oven and dry at 70°C for 2 hours to obtain a dry powder;

[0060] a4. C...

Embodiment 3

[0070] This embodiment prepares TiCl by the following steps 4 Post-treated SnO 2 Nano film:

[0071] A, repeat step a, step b and step c of embodiment 1 to obtain unprocessed SnO 2 nano film;

[0072] b. Untreated SnO 2 The nano film is immersed in TiCl with a concentration of 75-150mmol / L (the optimal value is 100mmol / L) and a temperature of 70°C 4 Heat treatment in aqueous solution for 30 minutes, then wash SnO with deionized water 2 The surface of the nanometer film is dried and placed in a muffle furnace for at least 120 minutes at 500 ° C to obtain a TiCl 4 Post-treated SnO 2 nano film. The specific sintering curves are sintering at 150°C for 10 minutes, sintering at 325°C for 10 minutes, sintering at 375°C for 10 minutes, sintering at 450°C for 30 minutes, and sintering at 500°C for 120 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com