Metal photovoltaic tile and preparation method thereof

A photovoltaic tile and metal tile technology, applied in photovoltaic power generation, photosensitive equipment, metal layered products, etc., can solve the problems of low utilization rate of photovoltaic cells, heavy and thick photovoltaic tiles, brittle and fragile, etc., and achieve photovoltaic output characteristics Good, large choice, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

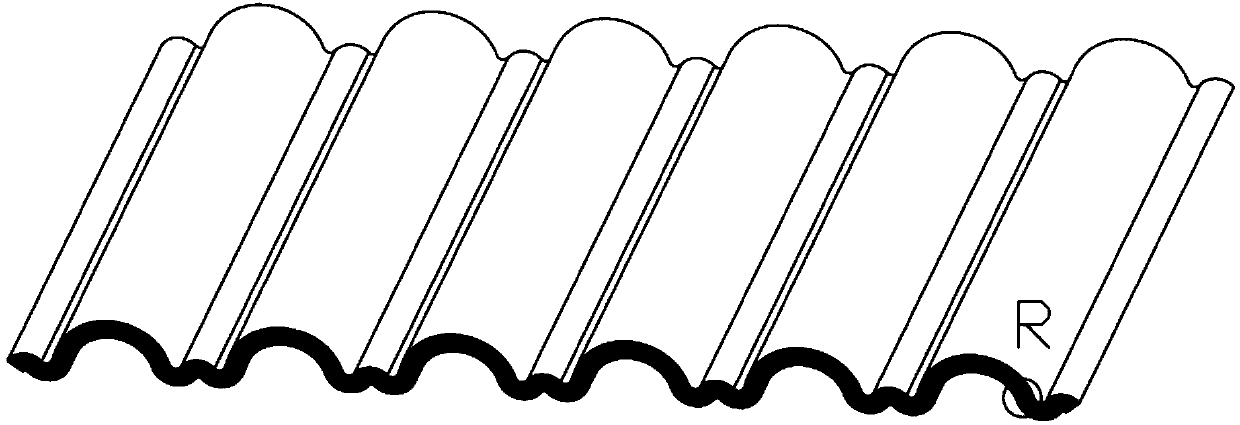

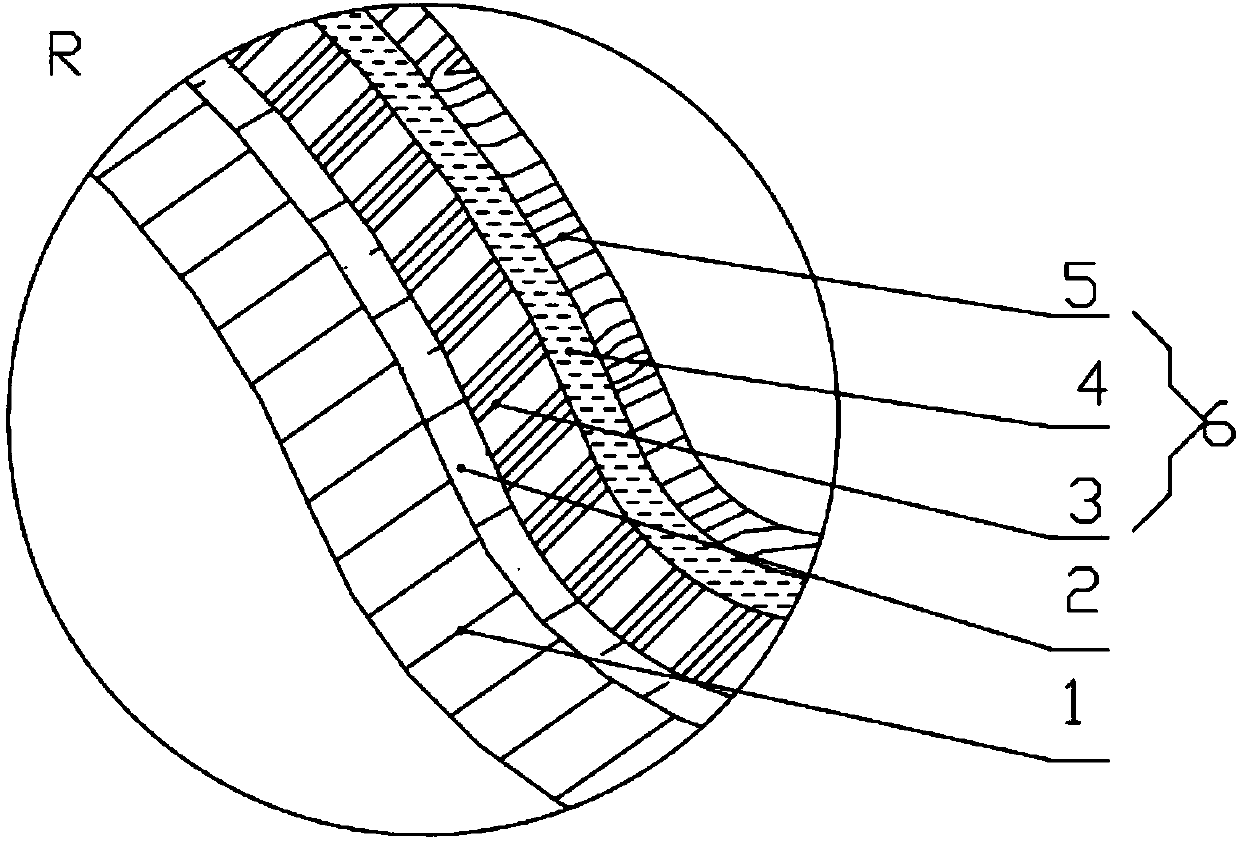

[0027] Such as figure 1 with figure 2 As shown, the metal photovoltaic tile of the present invention includes a metal tile substrate 1 and a photovoltaic decoration layer 6, and the photovoltaic decoration layer 6 is bonded to the upper surface of the metal tile substrate 1 by an adhesive 2 to form an integral structure. The metal photovoltaic tile substrate 1 is a high-corrosion-resistant galvanized steel plate with a length of 1090mm, a width of 380mm, a thickness of 0.3mm, and a weight of 2.3kg / m 2 . The surface of the metal tile substrate 1 is coated with an interface agent for improving adhesion, and the interface agent is an emulsion containing polyacrylate resin.

[0028] The photovoltaic decoration layer 6 includes a flexible thin film battery assembly 3, a film layer 4 and a paint layer 5 from the inside to the outside; the flexible thin film battery assembly 3 is prepared by depositing a transparent conductive film on a bendable flexible substrate such as plastic ...

Embodiment 2

[0030] The metal photovoltaic tile substrate 1 is a highly corrosion-resistant galvanized steel plate with a length of 1700mm, a width of 420mm, a thickness of 0.6mm, and a weight of 3.4kg / m 2. The binder 2 is a flame-retardant polymer quick-setting binder, which is composed of the following components in mass percentage: 55% of organic silicon acrylic emulsion, 8.5% of organic phosphorus nitrogen flame retardant, crosslinking agent 25%, solvent 11.5%, wherein, the crosslinking agent is an acrylic ester crosslinking agent, and the solvent is an ether solvent. The surface of the metal tile substrate 1 is coated with an interface agent for improving adhesion, and the interface agent is a solution containing polyacrylate resin. The flexible thin film battery assembly 3 is a copper indium potassium selenide thin film solar cell; the thickness of the coating layer 5 is 70um, and the others are the same as in the first embodiment.

Embodiment 3

[0032] The metal photovoltaic tile substrate 1 is a highly corrosion-resistant galvanized steel plate with a length of 1500mm, a width of 400mm, a thickness of 0.5mm, and a weight of 3kg / m 2 . The binder 2 is a flame-retardant polymer rapid-hardening binder, which is composed of the following components in mass percentage: 65% of silicone acrylic emulsion, 5% of organic phosphorus nitrogen flame retardant, crosslinking agent 15%, solvent 15%, wherein, the crosslinking agent is an organosilicon crosslinking agent, and the solvent is a lipid solvent. The surface of the metal tile substrate 1 is coated with an interface agent for improving adhesion, and the interface agent is an emulsion containing polyvinyl alcohol resin (or a solution containing polyvinyl alcohol resin). The flexible thin-film battery assembly 3 is a cadmium telluride thin-film solar cell;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com