Fishy flavor agent for feed and preparation method of fishy flavor agent

A technology for flavoring agent and fishy fragrance, which is applied to the field of fishy fragrance flavoring agent and its preparation, can solve problems such as resource waste, and achieve the effects of solving waste, easy preservation, and simple and easy preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

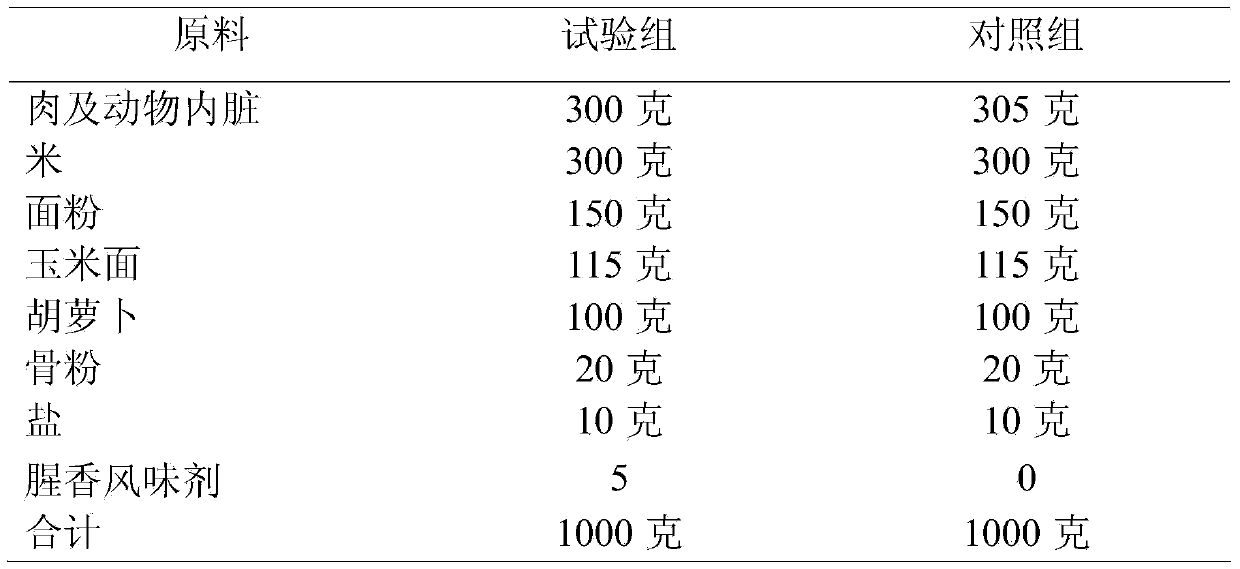

Image

Examples

preparation example Construction

[0017] The preparation method of above-mentioned fishy flavor flavor agent is:

[0018] A, preparation of fishy smell reactant: a, meat waste (artificially raised animals include pigs, cattle, chickens, fish waste) after colloidal grinding, add hydrolytic protease 0.1% and flavor protease 0.2% by its quality , after enzymatic hydrolysis at 55°C for 4 hours, the temperature was raised to 100°C to inactivate the enzyme for 30 minutes to obtain an enzymatic hydrolysis solution; b. Add 85% of the enzymatic hydrolysis solution, 2% arabinose, and 1 %, 5% of yeast extract, 0.5% of thiamine, 1% of glutamic acid, 0.5% of methionine, 2.5% of arginine and 2.5% of salt, and reacted at 100°C for 2 hours, and obtained a fishy smell reaction product after cooling;

[0019] B. Mix furanone, ethyl maltol and glycerol triacetate in a stainless steel container, stir until completely dissolved, then add other aroma raw materials, and then fully stir to complete the preparation.

[0020] After re...

Embodiment 1

[0022] Betaine 1%; Trimethylamine 1%; 2-Methyl-3-Mercaptofuran 0.1%; Tetrahydropyrrole 0.3%; Hexahydropyridine 0.3%; Phenylethylamine 0.8%; 2-acetylpyridine 0.03%; Furanone 0.4%; ethyl maltol 1%; 2-acetylpyrazine 1.5%; 2,3,5-trimethylpyrazine 1.5%; 3-methylthiopropionaldehyde 0.5%; fishy smell reactant 40%; Triacetin 51.57%.

[0023] The preparation process of the above-mentioned astringent flavoring agent: take pig and chicken waste (including bones, viscera, etc.) Inactivate the enzyme at 100°C for 30 minutes to obtain the enzymatic solution; add 85% of the enzymatic solution, 2% of arabinose, 1% of L-cysteine hydrochloride, 5% of yeast extract, and thiamine to the reaction kettle 0.5%, 1% glutamic acid, 0.5% methionine, 2.5% arginine and 2.5% salt were reacted at 100°C for 2 hours, and the fishy smell reactant was obtained after cooling; furanone, ethyl maltol and Glycerin triacetate is mixed and stirred until it is completely dissolved, then other aroma raw materials a...

Embodiment 2

[0028] Betaine 1.5%; Trimethylamine 3%; 2-Methyl-3-Mercaptofuran 1%; Tetrahydropyrrole 0.5%; Hexahydropyridine 0.5%; Phenylethylamine 1%; 2-acetylpyridine 0.5%; Furanone 0.5%; ethyl maltol 2%; 2-acetylpyrazine 2%; 2,3,5-trimethylpyrazine 2%; 3-methylthiopropanal 1%; fishy smell reactant 50%; Triacetin 34.5%.

[0029] The preparation process of the above-mentioned fishy-flavor flavoring agent: take cattle, fish, chicken waste (including bones, viscera, etc.) Heat up to 100°C to inactivate the enzyme for 30 minutes to obtain the enzymatic hydrolysis solution. Add 85% of enzymatic solution, 2% of arabinose, 1% of L-cysteine hydrochloride, 5% of yeast extract, 0.5% of thiamine, 1% of glutamic acid and 0.5% of methionine into the reaction kettle %, 2.5% arginine, 2.5% salt, react at 100°C for 2 hours, and get a fishy smell reaction product after cooling; first mix furanone, ethyl maltol and glyceryl triacetate in a stainless steel container, and stir until completely dissolved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com