Injectable liquid metal bone cement, preparation method of injectable liquid metal bone cement and special injection device for injectable liquid metal bone cement

A technology of liquid metal and bone cement, applied in X-ray contrast agent preparation, medical science, joint implants, etc., can solve the problems of endangering human health and complicated operation, and achieve short curing time, simple operation and fast curing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] First, liquid metal bone cement material 1 is prepared, which uses a bismuth (Bi)-based alloy:

[0039] Metal bismuth (Bi), metal indium (In), metal tin (Sn) and metal zinc (Zn) were mixed in an empty beaker according to the mass fractions of 35%, 48.7%, 15.9% and 0.4%. Put the beaker into a vacuum oven and heat continuously for 20 hours at a temperature of 360°C. At this time, several metals are mixed together to form a molten metal state. In order to ensure the uniformity of the alloy composition, put it on a magnetic stirring heater, heat and melt it at 160°C, and fully stir it for 4 hours. The obtained low melting point alloy had a melting point of 59.1°C. The prepared low-melting-point alloy bone cement can be stored at room temperature for a long time after being sealed.

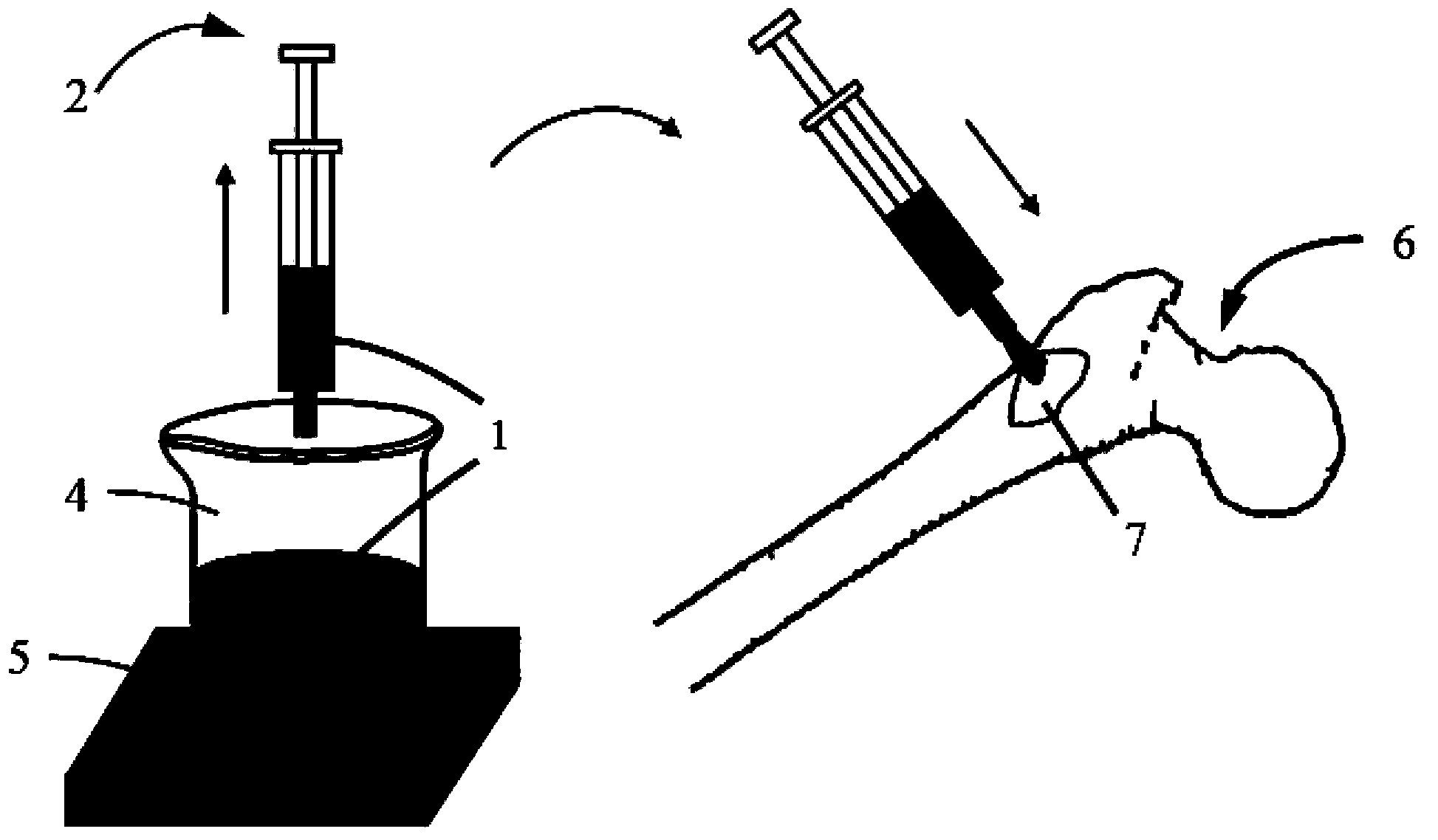

[0040] After the preparation of the liquid metal bone cement material 1 is completed, it can be filled into the target area and solidified to form a support body 3, which is used for artifici...

Embodiment 2

[0046] The difference from Example 1 is that the liquid metal bone cement material in this example is a gallium (Ga)-based alloy, and its composition is: the mass percentage of metal gallium (Ga) is 40%, metal indium (In) The mass percentage content of tin is 30%, and the mass percentage content of metal tin (Sn) is 30%. Other materials and steps are the same as in Example 1.

Embodiment 3

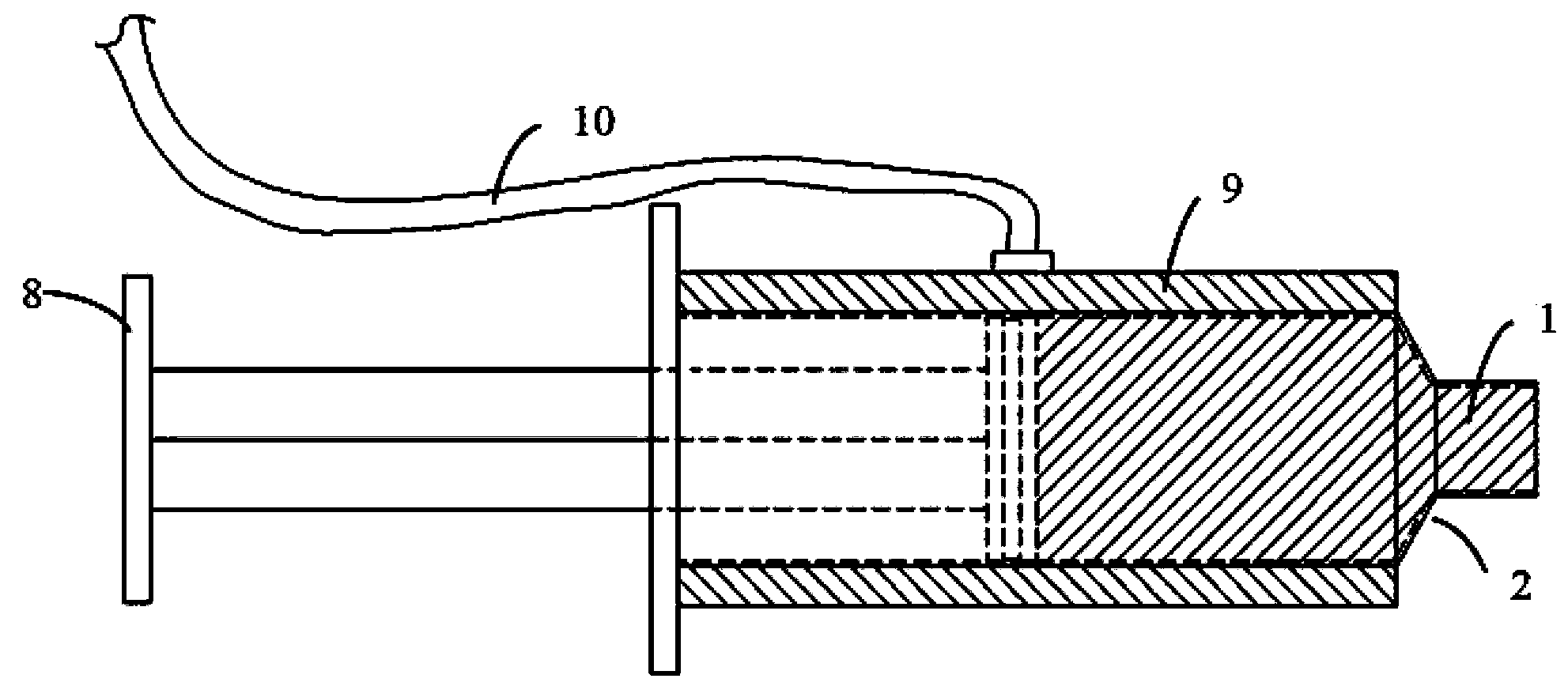

[0048] Different from Example 1, this example uses a special injection device for injection, such as figure 2 As shown, the special injection device adds an insulation layer or heating device 9 to the outside of the syringe 2, and uses external equipment to control the temperature of the insulation layer or heating device 9 through the connection line 10, so that the temperature is controllable and measurable.

[0049] Because the liquid metal bone cement material 1 has a low melting point and a fast solidification speed, the special injection device in this embodiment can keep it in a liquid state for a long time in the injection device, preventing it from solidifying in the syringe. Before the liquid metal bone cement material 1 is sucked into the syringe 2, an external control device is used to heat the insulation layer or the heating device 9 outside the syringe 2. Through the built-in temperature sensor of the insulation layer or the heating device 9, the temperature val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com