High-strength temperature resistance porous phenolic resin foam and preparation method thereof

A technology of phenolic resin foam and phenolic resin, which is applied in the field of phenolic resin foam and its preparation, can solve the problems of insufficient mechanical strength, insufficient temperature resistance, insufficient water absorption, and easy slag drop, and achieve enhanced mechanical strength and temperature resistance High performance, not easy to drop slag, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

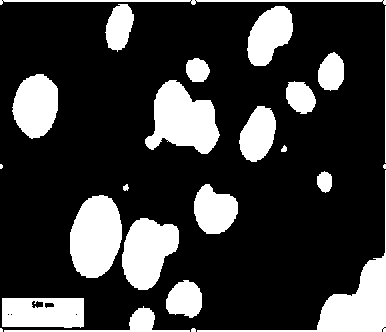

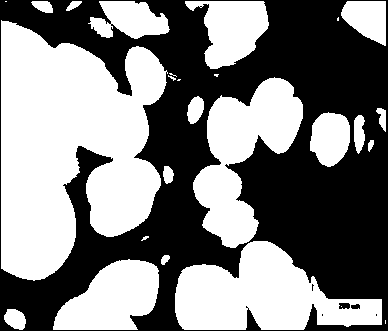

Image

Examples

Embodiment 1

[0041] 1. Synthetic resin and chemical modification

[0042] Add 94 parts of phenol and 30 parts of epoxy resin (brand: E51: ESR618, purchased from Nantong Xingchen Synthetic Materials Co., Ltd.) into the three-necked flask, stir at room temperature for 5 minutes until uniform, and then add 20 parts of 20wt% to the three-necked flask NaOH aqueous solution, heated and stirred for 15 minutes; when the temperature rose to 80°C, 56.85 parts of solid formaldehyde were added in 4 batches on average, and the time interval between each batch was 10 minutes; after 3.0h, the reaction was terminated, and the obtained modified phenolic The resin was cooled to room temperature.

[0043] 2. Foaming and curing

[0044]1) Add 100 parts of modified phenolic resin and 2 parts (combined with 1 part of simethicone and 1 part of sodium dodecylsulfonate (SDS)) of compound surfactant in sequence to a high-speed mixer at room temperature, and Stir for 5 minutes;

[0045] 2) Then add 4 parts of...

Embodiment 2

[0052] 1. Synthetic resin and chemical modification

[0053] Add 94 parts of phenol and 14.1 parts of epoxy resin (brand E51: ESR618, purchased from Nantong Xingchen Synthetic Materials Co., Ltd.) into a three-necked flask, stir at room temperature for 5 minutes until uniform, and then add 22 parts of 20wt% NaOH aqueous solution, heated and stirred for 10 minutes; when the temperature rose to 80°C, 56.85 parts of solid formaldehyde were added in 4 batches on average, and the time interval between each batch was 10 minutes; after 3.0h, the reaction was completed, and the obtained modified phenolic resin Cool to room temperature.

[0054] 2. Foaming and curing

[0055] 1) Add 150 parts of modified phenolic resin and 8 parts (combined with 2 parts of OP-10 and 6 parts of SDS) of compound surfactant in turn into a high-speed mixer at room temperature, and stir at high speed for 5 minutes;

[0056] 2) Then add 12 parts of cyclopentane and stir at high speed for 1 minute to obtai...

Embodiment 3

[0063] 1. Synthetic resin and chemical modification

[0064] Add 94 parts of phenol and 14.1 parts of epoxy resin (brand name: E44 (Phoenix brand)) into the three-necked flask, stir at room temperature for 5 minutes until uniform, then add 24.6 parts of 20wt% NaOH aqueous solution to the three-necked flask, heat and Stir for 13 minutes; when the temperature rises to 80°C, add 56.85 parts of solid formaldehyde in 4 batches on average, with an interval of 10 minutes between each batch; after 3.0 hours, the reaction is terminated, and the obtained modified phenolic resin is cooled to room temperature.

[0065] 2. Foaming and curing

[0066] 1) Add 100 parts of modified phenolic resin and 4 parts (combined with 1.3 parts of Tween-80 and 2.7 parts of SDS) of compound surfactant in sequence to a high-speed mixer at room temperature, and stir at high speed for 5 minutes;

[0067] 2) Then add 10 parts of cyclopentane and stir at high speed for 1 minute to obtain a resin mixture;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com