Thermal treatment technology of large-size high-strength wrought magnesium alloy forging

A deformed magnesium alloy, large-size technology, applied in the field of heat treatment of large-scale deformed magnesium alloy forgings, can solve problems such as uneven performance, complex shape die forgings, and different deformations, so as to improve mechanical properties and eliminate uneven energy storage. The effect of superior uniformity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, large-scale deformed magnesium alloy forgings are used as raw materials; the large-scale deformed magnesium alloy forgings are magnesium-aluminum-zinc series deformed magnesium alloy forgings, and the mass percentages of each element are: Al8.2-8.5; Zn0.4-0.5 ; Mn0.2-0.25; Cu≦0.05; Ni≦0.005; Si≦0.15; Be≦0.02; Fe≦0.05; other impurities≦0.3;

[0038] Load the large-scale deformed magnesium alloy forging into a cold furnace, raise the temperature to 100°C for aging treatment for 38 hours, then set the temperature at 170°C, the heating time is 4 hours, heat it for 15 hours after rising to 170°C, and finally air-cool to room temperature to obtain a large Dimensional high strength wrought magnesium alloy forgings.

Embodiment 2

[0040] In this embodiment, large-scale deformed magnesium alloy forgings are used as raw materials; the large-scale deformed magnesium alloy forgings are magnesium-aluminum-zinc series deformed magnesium alloy forgings, and the mass percentages of each element are: Al8.2-8.5; Zn0.4-0.5 ; Mn0.2-0.25; Cu≦0.05; Ni≦0.005; Si≦0.15; Be≦0.02; Fe≦0.05; other impurities≦0.3;

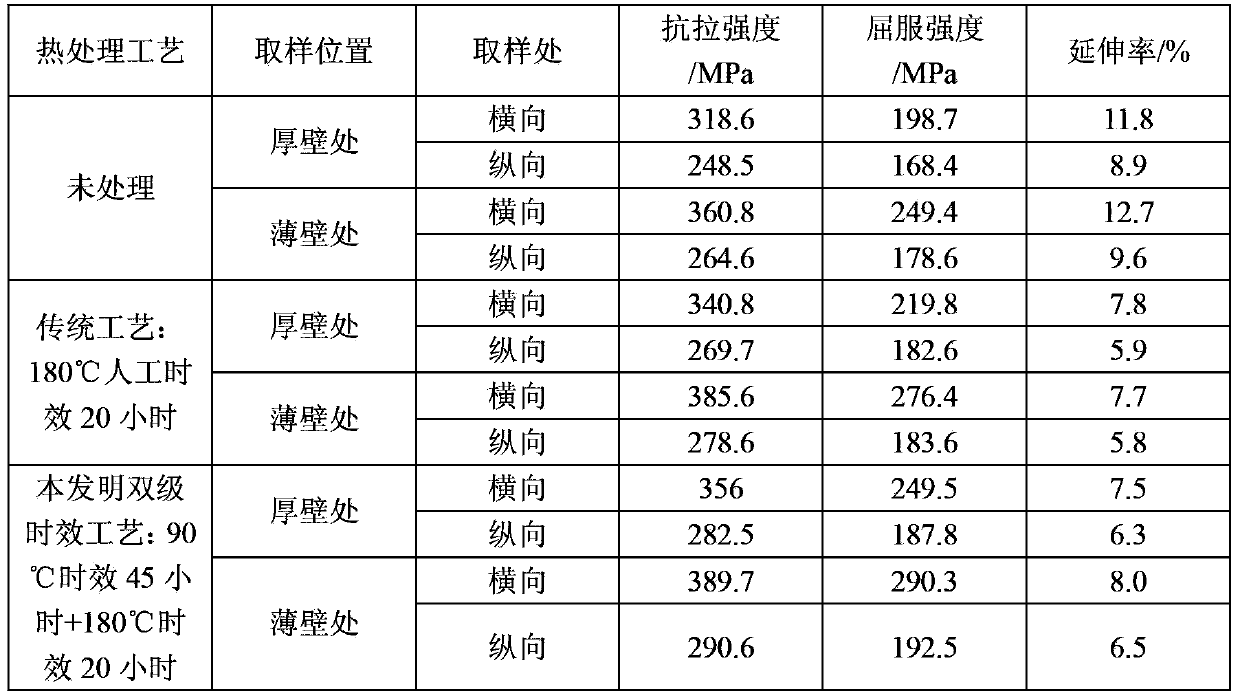

[0041] Load the large-scale deformed magnesium alloy forgings into a cold furnace, raise the temperature to 90°C for 45 hours of aging treatment, then set the temperature at 180°C, and the heating time is 3 hours, after rising to 180°C, keep the temperature for 20 hours, and finally air-cool to room temperature; The high-strength deformed magnesium alloy forgings were tested for their mechanical properties, and the test results are shown in Table 1.

[0042] It can be seen from Table 1 that after the double-stage aging process of this embodiment, the mechanical properties of the thick-walled and thin-walled parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com