Preparation method of bismuth nanocrystalline

A bismuth nanometer, bismuth hydroxide technology, applied in nanotechnology, chemical instruments and methods, single crystal growth and other directions, to achieve the effects of good stability, easy control of experimental conditions, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] At room temperature, 0.64g (0.002mol) BiCl 3 , 50mL of 0.5mol / L NaOH aqueous solution was added to a 100mL beaker, magnetically stirred for 30 minutes, centrifuged after the reactants no longer changed, the supernatant was discarded, and the pale yellow bismuth hydroxide precipitate was added to a 150mL deionized water In a beaker, stir well and then add 0.2g o-phenanthroline, stir at room temperature for 1 hour, use a constant pressure funnel to drop 100mL of 0.1mol / L NaBH at a rate of 1-2 drops / second 4 Aqueous solution, BiCl 3 With NaOH, o-phenanthroline, NaBH 4 The mol ratio of the solution is 1:12.5:0.5:5. After the dropwise addition, continue to stir for 2 hours, and the gained solution is centrifuged 3 times with absolute ethanol and deionized water at a speed of 4200 rpm to obtain a black precipitate. The black precipitate was dried at a constant temperature of 40° C. for 4 hours to obtain gray-black bismuth nanocrystals.

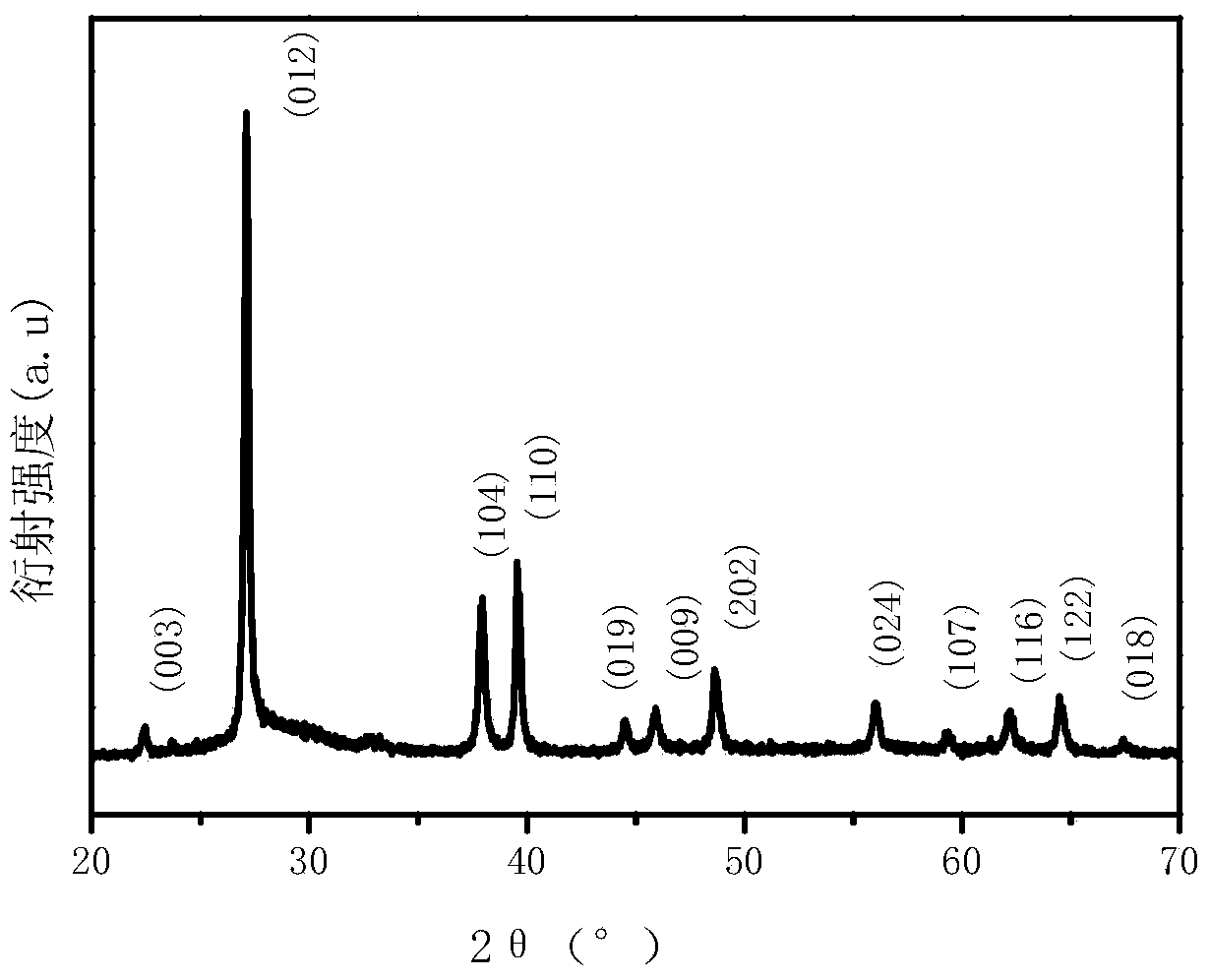

[0016] The prepared product was cha...

Embodiment 2

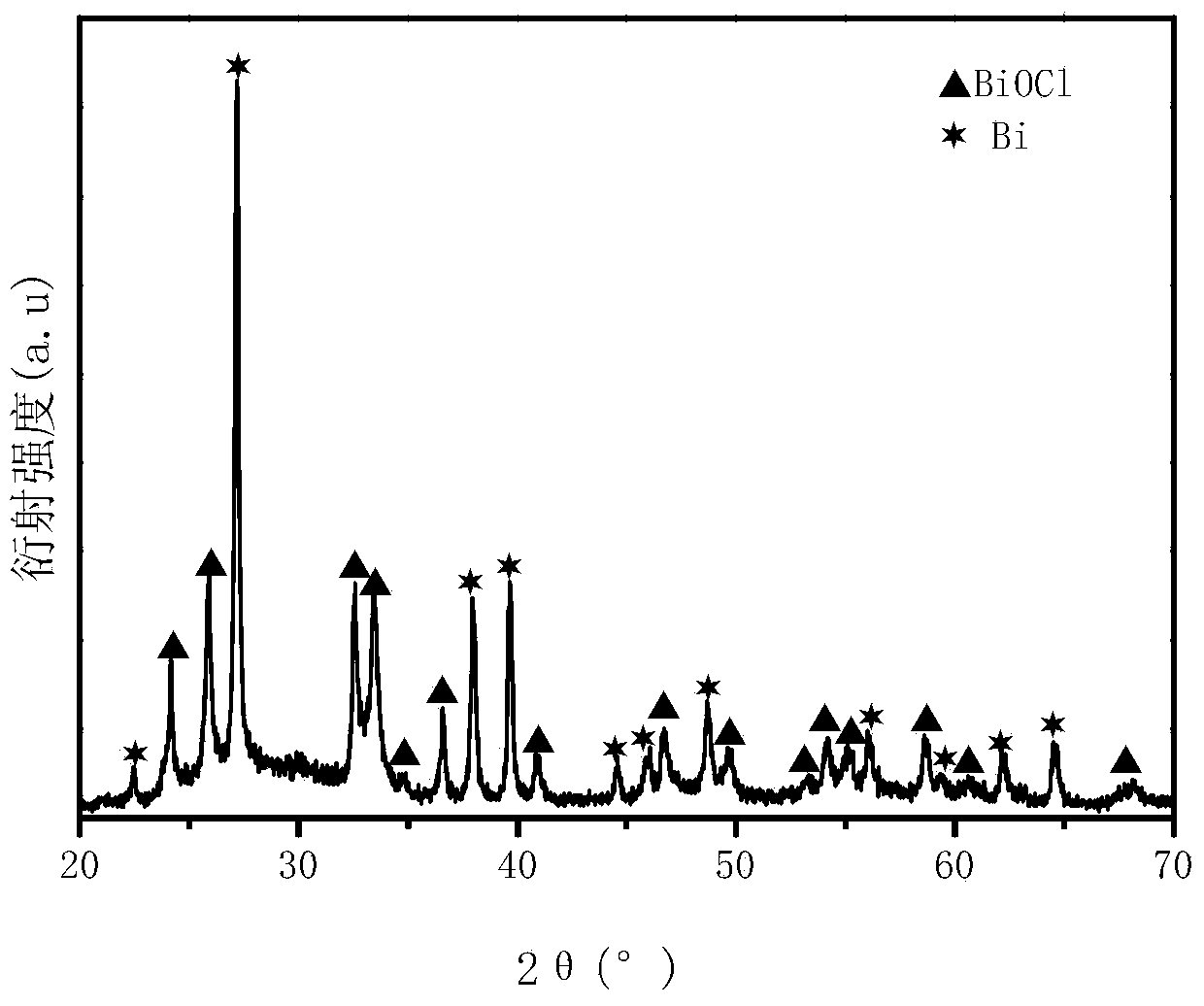

[0021] At room temperature, 0.64g (0.002mol) BiCl 3 , Add 20mL of 0.5mol / L NaOH aqueous solution into a 100mL beaker, stir magnetically for 60 minutes, centrifuge after the reactants no longer change, discard the supernatant, and add the pale yellow bismuth hydroxide precipitate into a 150mL deionized water In a beaker, stir well and then add 0.05g o-phenanthroline, stir at room temperature for 2 hours, use a constant pressure funnel to drop 20mL of 0.1mol / L NaBH at a rate of 1-2 drops / second 4 Aqueous solution, BiCl 3 With NaOH, o-phenanthroline, NaBH 4 The mol ratio of the solution is 1:5:0.125:1. After the dropwise addition, continue to stir for 2 hours, and the solution obtained is centrifuged 5 times with dehydrated alcohol and deionized water at a speed of 4200 rpm to obtain a black precipitate. The black precipitate was dried at a constant temperature of 40°C for 4 hours to obtain gray-black bismuth nanocrystals (see Figure 4 ).

Embodiment 3

[0023] At room temperature, 0.64g (0.002mol) BiCl 3 , Add 60mL of 0.5mol / L NaOH aqueous solution into a 100mL beaker, stir magnetically for 30 minutes, centrifuge after the reactants no longer change, discard the supernatant, and add the pale yellow bismuth hydroxide precipitate into a beaker containing 150mL deionized water In a beaker, stir well and then add 0.4g o-phenanthroline, stir at room temperature for 1 hour, add 200mL of 0.1mol / L NaBH dropwise at a rate of 1-2 drops / second with a constant pressure funnel 4 Aqueous solution, BiCl 3 With NaOH, o-phenanthroline, NaBH 4 The mol ratio of the solution is 1:15:1:10. After the dropwise addition, continue to stir for 1 hour, and the solution obtained is centrifuged 3 times with absolute ethanol and deionized water at a speed of 4200 rpm to obtain a black precipitate. The black precipitate was dried at a constant temperature of 50°C for 5 hours to obtain gray-black bismuth nanocrystals (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com