Preparation method of optical composite nano-fiber material

A composite nanofiber, optical technology, applied in luminescent materials, chemical instruments and methods, fiber processing, etc., can solve problems such as unsatisfactory solid loading and poor electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

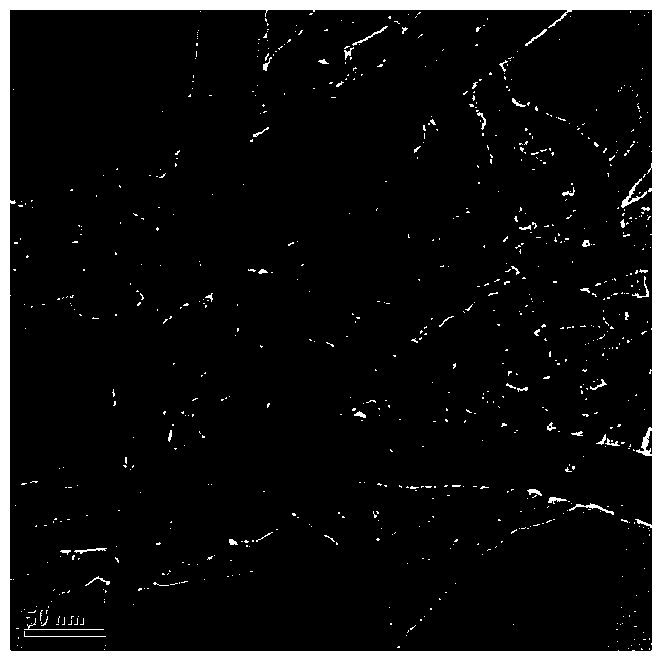

[0039] Transmission electron microscopy (TEM) of Au-MCNTs ( figure 1 ) It can be seen that the gold nanoparticles are evenly arranged along the outer wall of the MCNT, and the diameter of the gold nanoparticles is about 12nm, spherical and very uniform. Au-MCNTs will not condense or change color when placed in the dark for several months.

[0040] Made of PA6-Au-MCNT-Ru(bpy) 3 2+ Field emission scanning electron microscopy (FESEM) images of optical composite nanofibers ( figure 2 ) It can be seen that PA6-Au-MCNT-Ru(bpy) 3 2+ Optical composite nanofibers are randomly oriented to form a nanofiber film with a porous 3D structure. The surface of the nanofibers is smooth and unobtrusive, and the diameter ranges from 50nm to 300nm.

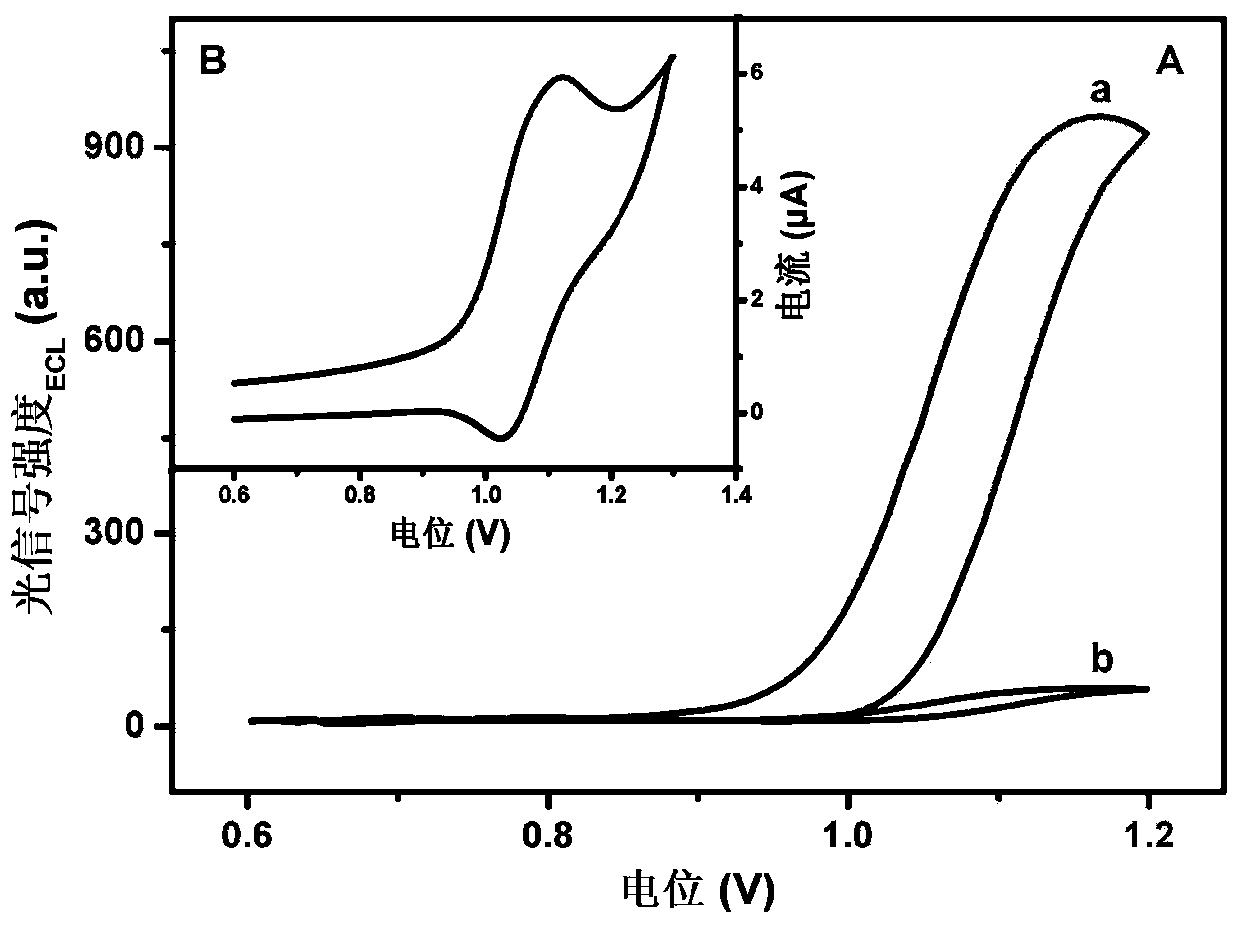

[0041] image 3 Cyclic voltammetry (CV) and electrochemiluminescence (ECL) were applied to PA6-Au-MCNT-Ru(bpy) 3 2+ Optical composite nanofibers were characterized. In the CV curve, there is an obvious oxidation peak at +1.07V (vs.Ag / AgCl) ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com