Direct printing method of low-temperature plasma processed fabric

A technology of low-temperature plasma and printing method, which is applied in the textile field, can solve the problems of weakening the strengthening effect of fabric fibers and dye molecules, and achieve the improvement of apparent depth and dyeing concentration, increase of fabric hydrophilicity and dye penetration, and increase absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Glow Discharge Plasma Treatment Nylon Rotary Screen Direct Printing

[0022] Fabric: 70D nylon fabric;

[0023] Plasma treatment: The equipment is HD-1A low-temperature plasma processor produced by Changzhou Shitai Plasma Technology Development Co., Ltd., and the fabric is treated with 100W, 50Pa nitrogen low-temperature plasma for 10 minutes;

[0024] Quaternary ammonium salt finishing: use roller coating equipment to fully coat the polyquaternium-2 solution with a mass percentage concentration of 30% on the surface of the fabric to be printed, and the coating amount is 1.0g / m 2 ;

[0025] Direct printing: Use rotary screen printing equipment to print directly through weak acid dye paste, steam to fix the color, wash and set the shape to get the printed product.

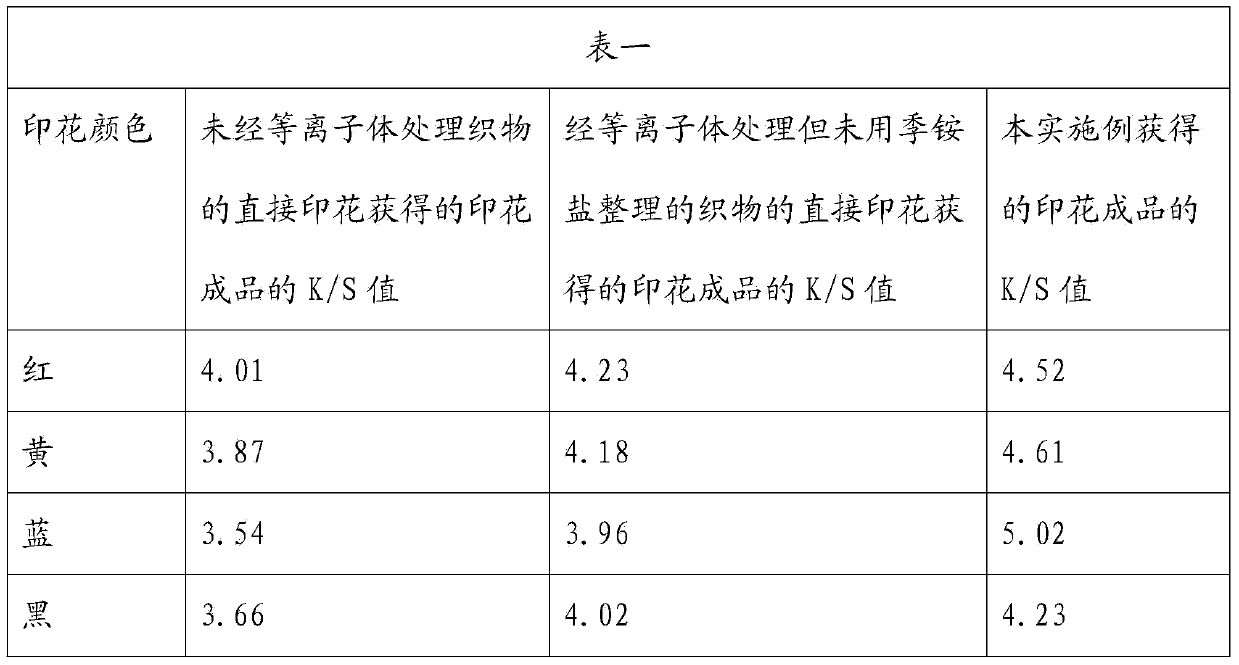

[0026] After testing, the color fastness to wet and dry rubbing of the finished printed product obtained in this example is 4-5 grades, the color fastness to washing is 4-5 grades, and the color fastness to...

Embodiment 2

[0029] Corona discharge plasma treatment polyester flat screen direct printing

[0030] Fabric: 300D*300D17g / m 2 polyester;

[0031] Plasma treatment: The equipment is the RF corona control system produced by Techmark (Beijing) Industrial Technology Development Co., Ltd. The fabric is treated by 20KV discharge voltage in the air and 30kHz high-frequency corona treatment;

[0032] Quaternary ammonium salt finishing: use roller coating equipment to fully coat the polyquaternium-7 solution with a mass percentage concentration of 60% on the surface of the fabric to be printed, and the coating amount is 0.8g / m 2 ;

[0033] Direct printing: use flat screen printing equipment to print directly through disperse dye color paste, bake at high temperature to fix the color, and then get the printed product after washing and setting.

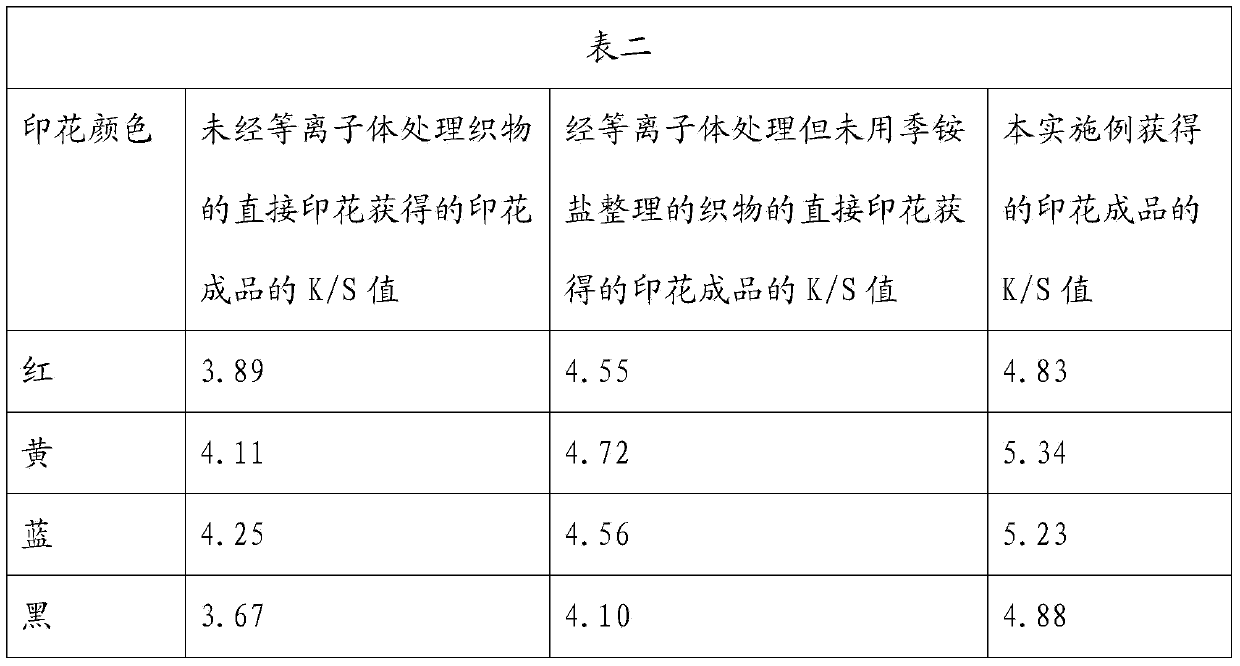

[0034] After testing, the color fastness to dry and wet rubbing of the finished printed product obtained in this example is 4-5 grades, the color fastnes...

Embodiment 3

[0037] Dielectric Barrier Discharge Plasma Treatment Wool Flat Screen Direct Printing

[0038] Fabric: 420g / m 2 Woven wool fabric;

[0039] Plasma treatment: dielectric barrier discharge plasma treatment equipment, the discharge medium is plexiglass, and the dielectric layer is

[0040] Polytetrafluoroethylene, the discharge gas is argon, and the fabric is treated with plasma for 15 minutes;

[0041] Quaternary ammonium salt finishing: use flat screen equipment to fully coat the polyquaternium-11 solution with a mass percentage concentration of 40% on the surface of the fabric to be printed, and the coating amount is 1.5g / m 2 ;

[0042] Direct printing: use flat screen printing equipment to print directly through KM dye color paste, after cold stacking to fix the color, and after washing and setting, the printed product can be obtained.

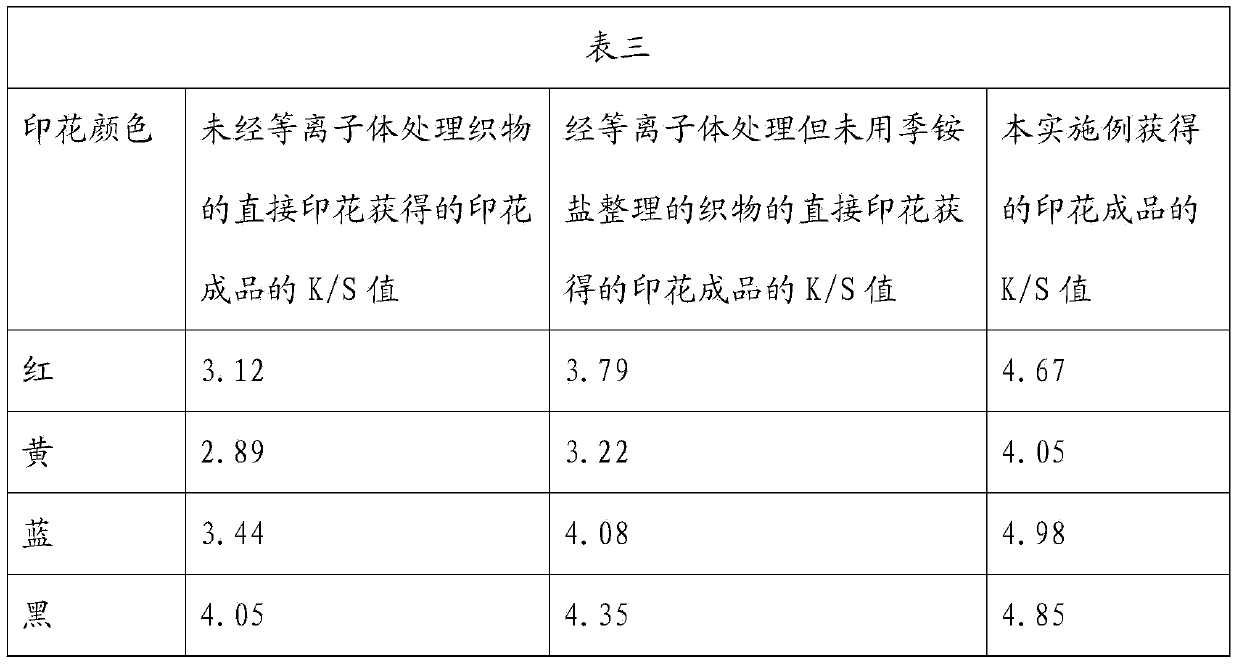

[0043] After testing, the color fastness to dry and wet rubbing of the finished printed product obtained in this example is grade 4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com