Novel casting furnace

A casting furnace, a new type of technology, used in furnaces, crucible furnaces, furnace types and other directions, can solve the problems of low economic efficiency, furnace cracking, and poor quality of use, and achieve safe and convenient operation, long maintenance cycle, and guaranteed quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

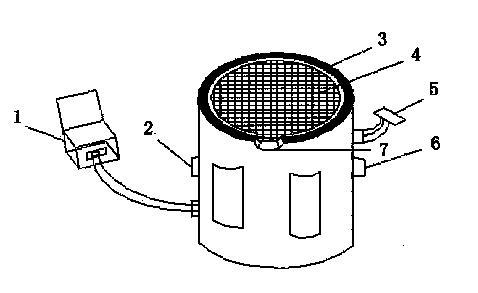

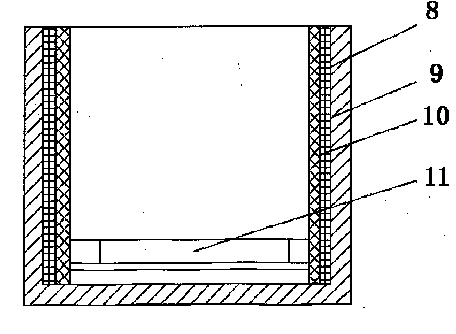

[0009] During actual assembly and use, the computer software program is designed and input into the computer according to the quality requirements of high-carbon steel, medium-carbon steel, low-carbon steel and different cast irons. It is used in conjunction with the spectrometer to detect various physical and chemical indicators three times per hour, and the molten iron is qualified. The rate is above 98%. The first layer in the furnace body of the casting furnace is the asbestos high temperature resistant layer, followed by the furnace frame structure layer. According to the tonnage of the casting furnace, round iron with high melting point and different specifications is selected, and it is cast and compacted with heat resistant mixed materials such as gold powder, quartz, and sand. On the cylindrical grid frame structure, the finished furnace is formed, and the electric furnace bar is formed into a coil shape to form uniform heating. The high-quality heat-resistant se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com