Narrow linewidth tunable laser system and method of operation

An operation method and laser technology, applied in the field of narrow linewidth tunable laser systems, can solve problems such as complex control, stability problems, and power failure of the laser, so as to solve the power failure problem, ensure safety, enhance robustness and The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

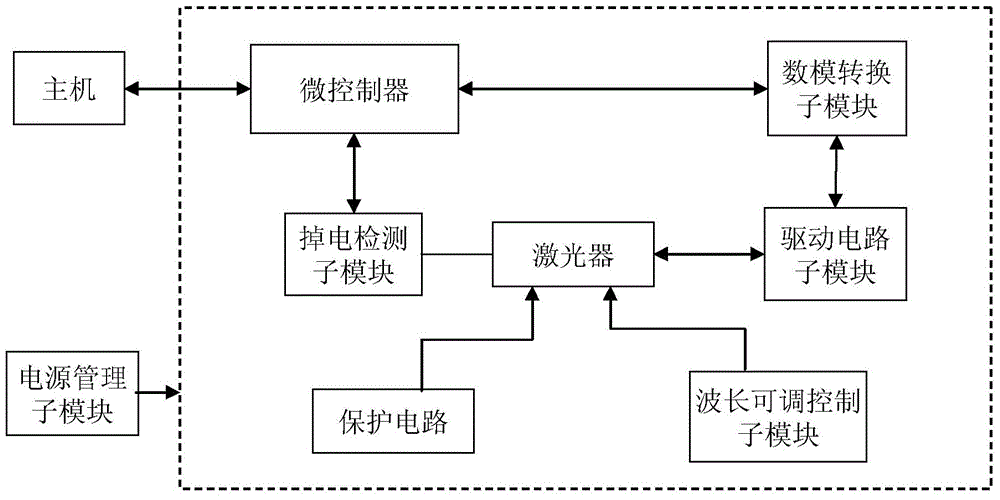

[0035] Narrow linewidth tunable laser system embodiment

[0036] The structural block diagram of the embodiment of the narrow linewidth tunable laser system is shown in figure 1 . The adjustable laser module includes a semiconductor laser, a driving circuit submodule mounted on a circuit board and connected to the laser, a wavelength adjustable control submodule, a power-off detection submodule and a protection circuit. The semiconductor laser in this example is a 26-pin butterfly cooling external cavity semiconductor laser. The microcontroller is connected to the digital-to-analog conversion sub-module through a serial peripheral interface SPI (Serial Peripheral Interface), and the output end of the digital-to-analog conversion sub-module is connected to the driving circuit sub-module.

[0037] This example uses the STC15L2K60S2 microcontroller, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com