Method for rapidly preparing supported zeolite inner-membranes

A zeolite inner membrane and support type technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of reducing growth, fast speed, and good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Zeolite inner membrane fixation assembly

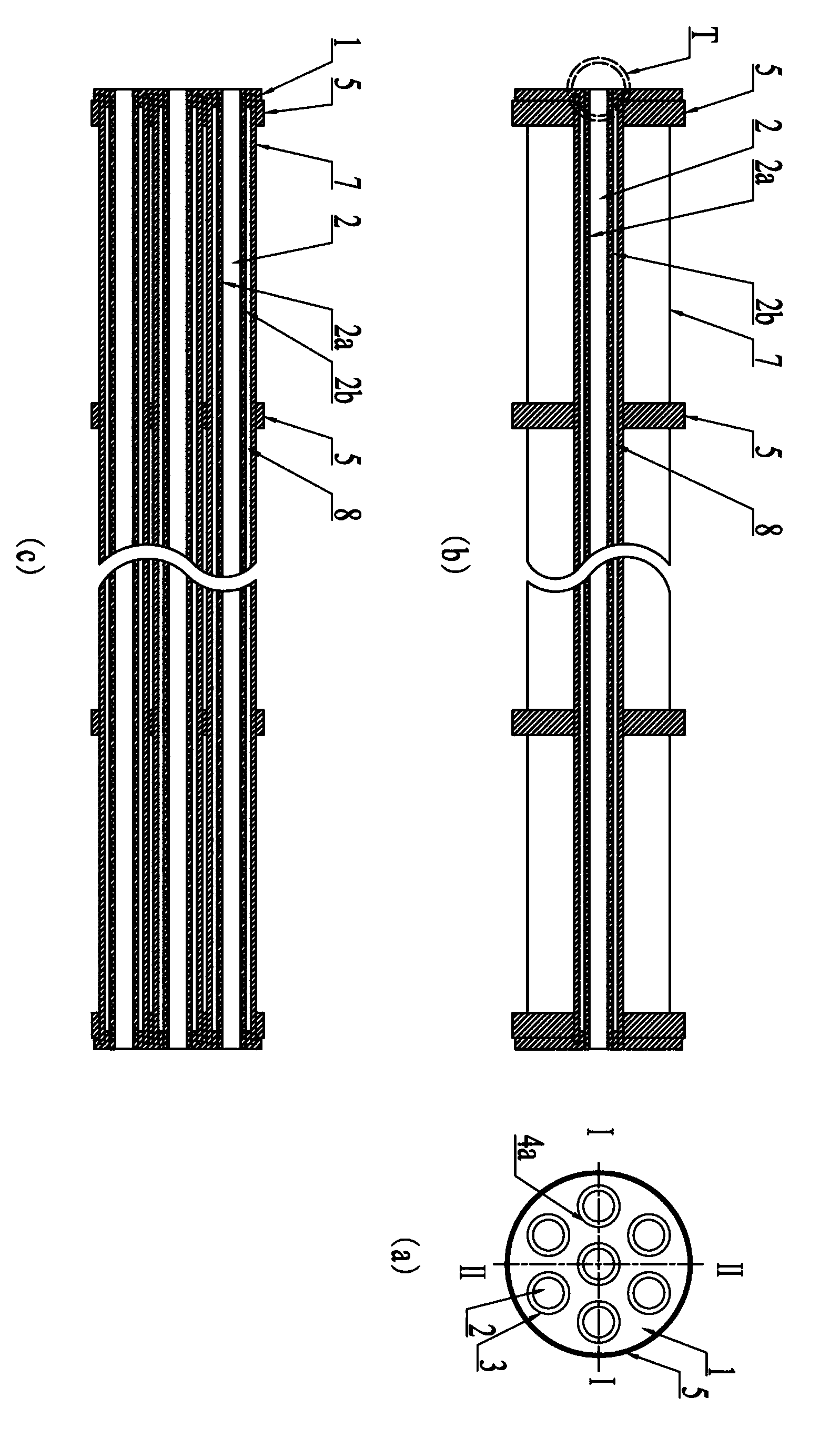

[0034] refer to figure 1 , a front view of a zeolite inner membrane fixing assembly equipped with a carrier tube according to a preferred embodiment of the present invention, which has the advantages of fast and uniform heating, short crystallization time, effective reduction of zeolite crystals entering the carrier pores and growth and suppression of intergranular defects The resulting zeolite inner membrane is usually thin and dense with high crystallinity.

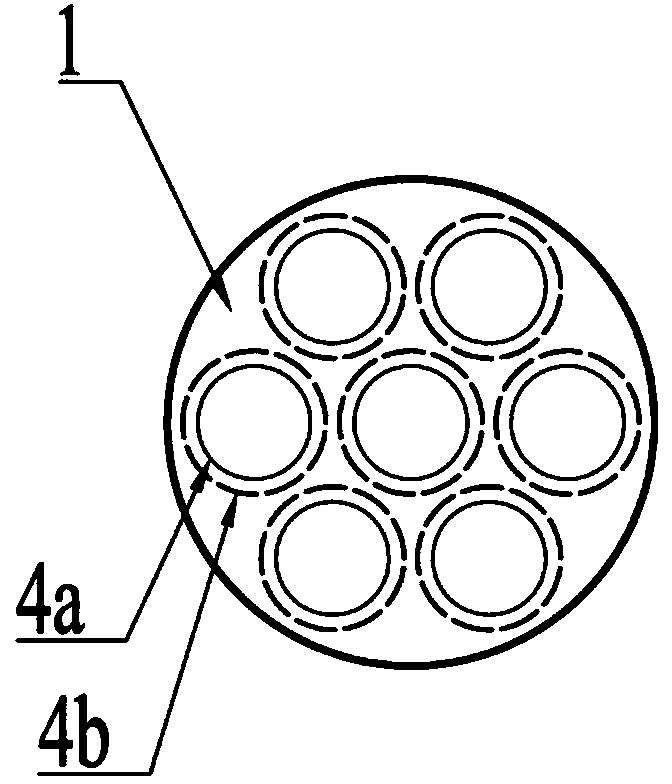

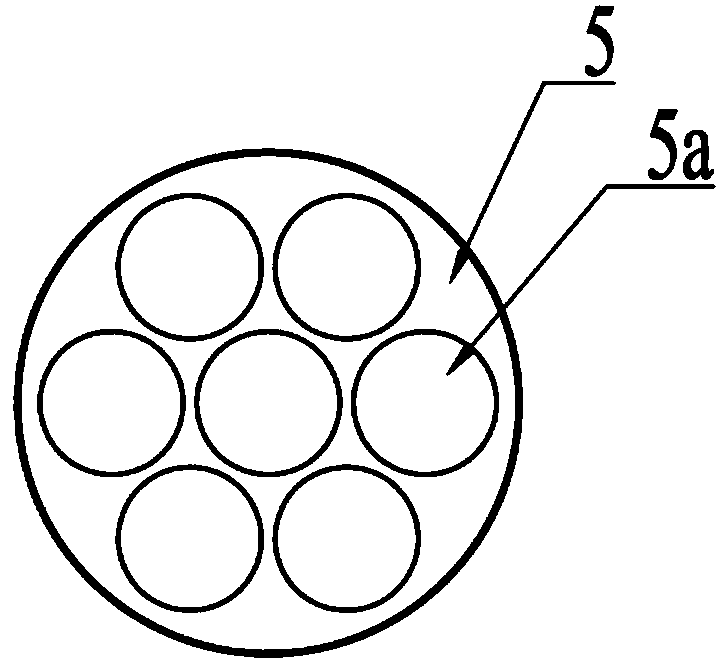

[0035] Such as Figure 1-4 As shown, the zeolite inner membrane fixing assembly involved in a preferred embodiment of the present invention mainly includes: connecting the sealing part 1, connecting the sealing carrier tube 2 and the protective sleeve 7 through the sealing pin 6, preventing the crystallization reaction liquid from contacting the carrier tube. The surface 2b is in direct contact, and the middle part of the sealing plug 6 is provided with a ...

Embodiment 2

[0037] Embodiment 2 Microwave film reaction device

[0038] A preferred embodiment of the present invention crystallization synthesis step adopts microwave film reaction device 001-C, such as Figure 5 As shown, the device mainly includes: reaction vessel body A1, which is made of polytetrafluoroethylene microwave-transparent material, and the inner cavity 18 of the reaction vessel can manufacture one or more 250-1500mm supported zeolite inner membranes at a time; the reaction vessel The internal cavity 18 of the zeolite contains the crystallization reaction liquid synthesized by the carrier tube 2; the ferrule 20 of the reaction vessel is installed on the surface of the zeolite A1 of the reaction vessel, and is made of mesh and stainless steel. It can increase the compressive strength of the reaction vessel body A1, reduce the thickness and weight of the reaction vessel body A1, so that it meets the standard requirements of the pressure reaction vessel, and does not hinder th...

Embodiment 3

[0042] Example 3 Preparation of Supported Zeolite Inner Membrane

[0043] First, self-made NaA zeolite molecular sieves with an average particle size of 2μm (large seed) and 400nm (small seed) were calcined to prepare a seed liquid of a certain concentration, and the concentrations of the large seed and small seed were 10wt .% and 1wt.%, and the molecular sieve can be fully dispersed by vigorous stirring and ultrasonic vibration. The first step is to pre-set large seeds by vacuum method, and the outer surface of the pre-polished single-channel porous α-alumina carrier tube with an average pore size of 2.2 μm, an outer diameter of 12 mm, an inner diameter of 8 mm, and a length of 1 m is used The fixed component of the zeolite inner membrane is tightly sealed, connect the vacuum buffer tank, then immerse the carrier tube 2 in the large seed liquid, open the vacuum valve for 20 seconds and take it out, then put the carrier tube coated with the large seed into an oven at 80-100°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com