Chain fluidization drying machine

A fluidized drying and chain-type technology, applied in the direction of dryers, drying solid materials, drying gas arrangement, etc., can solve the problem of low production rate of aluminum sulfate or ammonium aluminum sulfate, unable to meet the roasting time, high corrosion resistance requirements of equipment, etc. problems, to achieve the effects of high reaction/drying efficiency, short construction time, and stable quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples. However, those skilled in the art understand that the following detailed description does not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

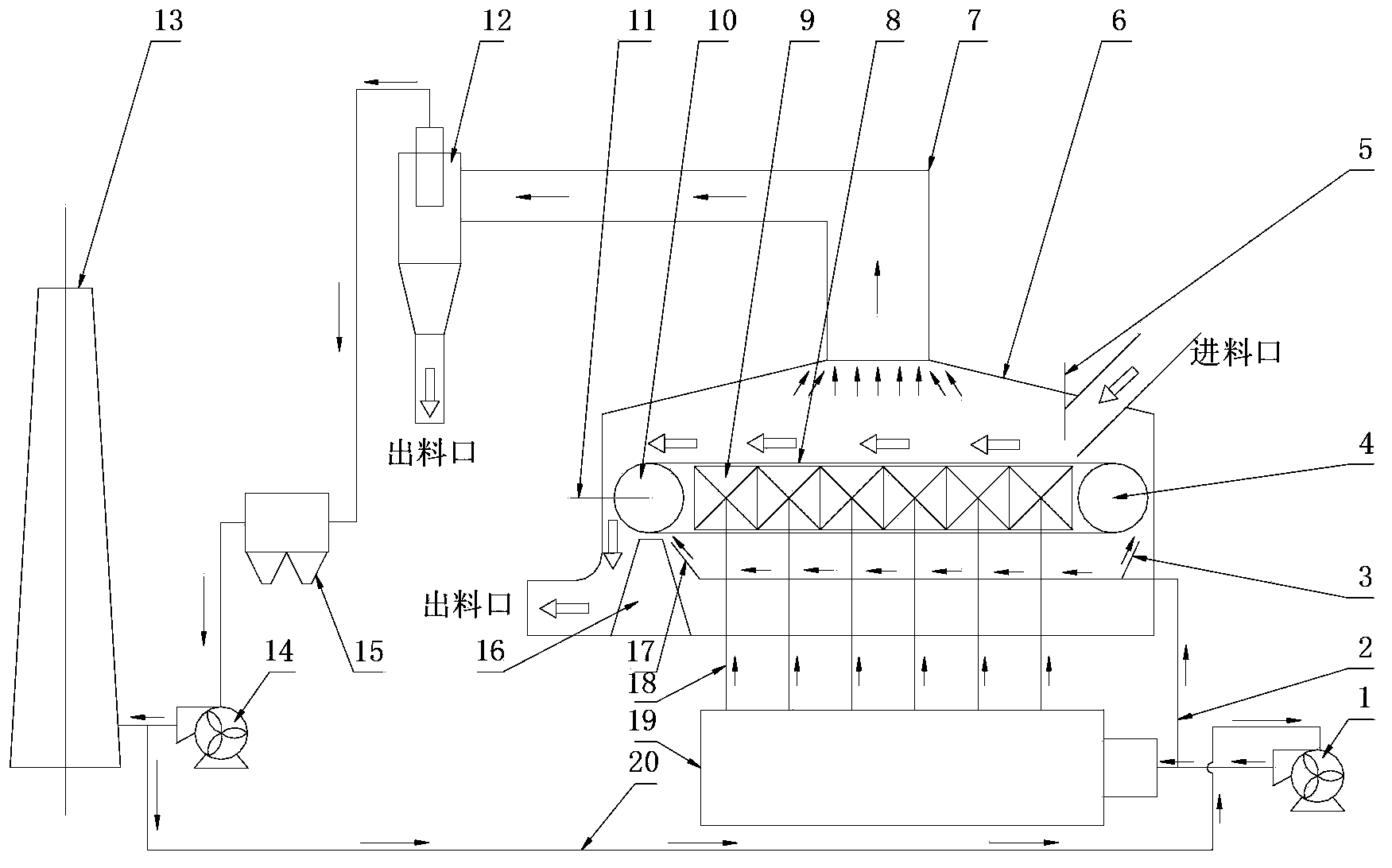

[0029] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is a chain type fluidized dryer, including the dryer body and its auxiliary equipment.

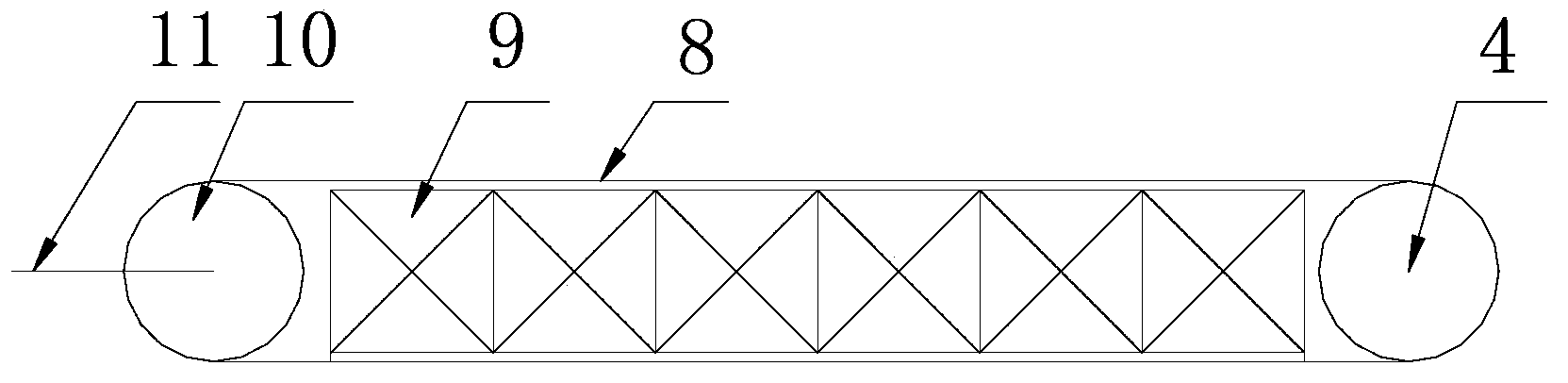

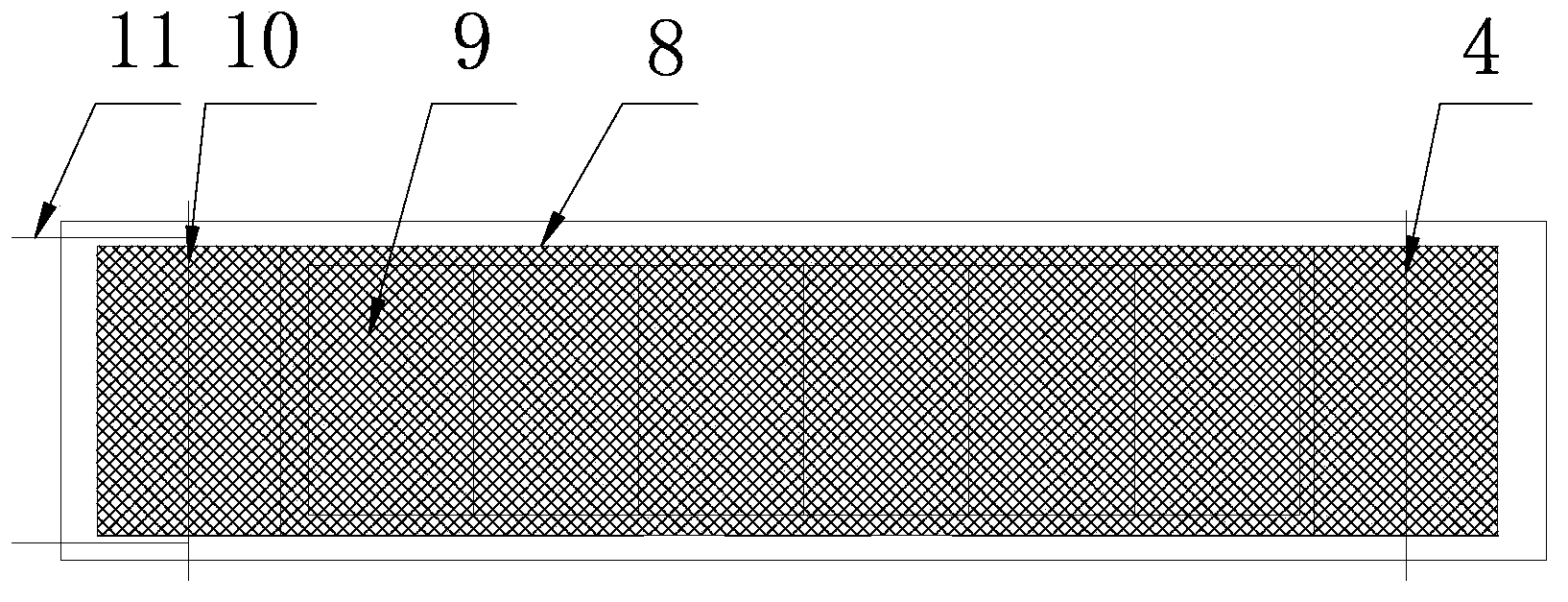

[0030] The dryer body includes: shell 6, driving idler 10 and driven idler 4 fixed on the shell 6, air distribution device 8 arranged on the active idler 10 and driven idler 4, fixed on the shell 6 and located below the air distribution device 8, one end of the air chamber 9 is connected to the driving roller 10 and the other end extends out of the housing 6. The tension and deviation adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com