Preparation method of bismuth-based strontium magnetic photo-catalyst, and bismuth-based strontium magnetic photo-catalyst

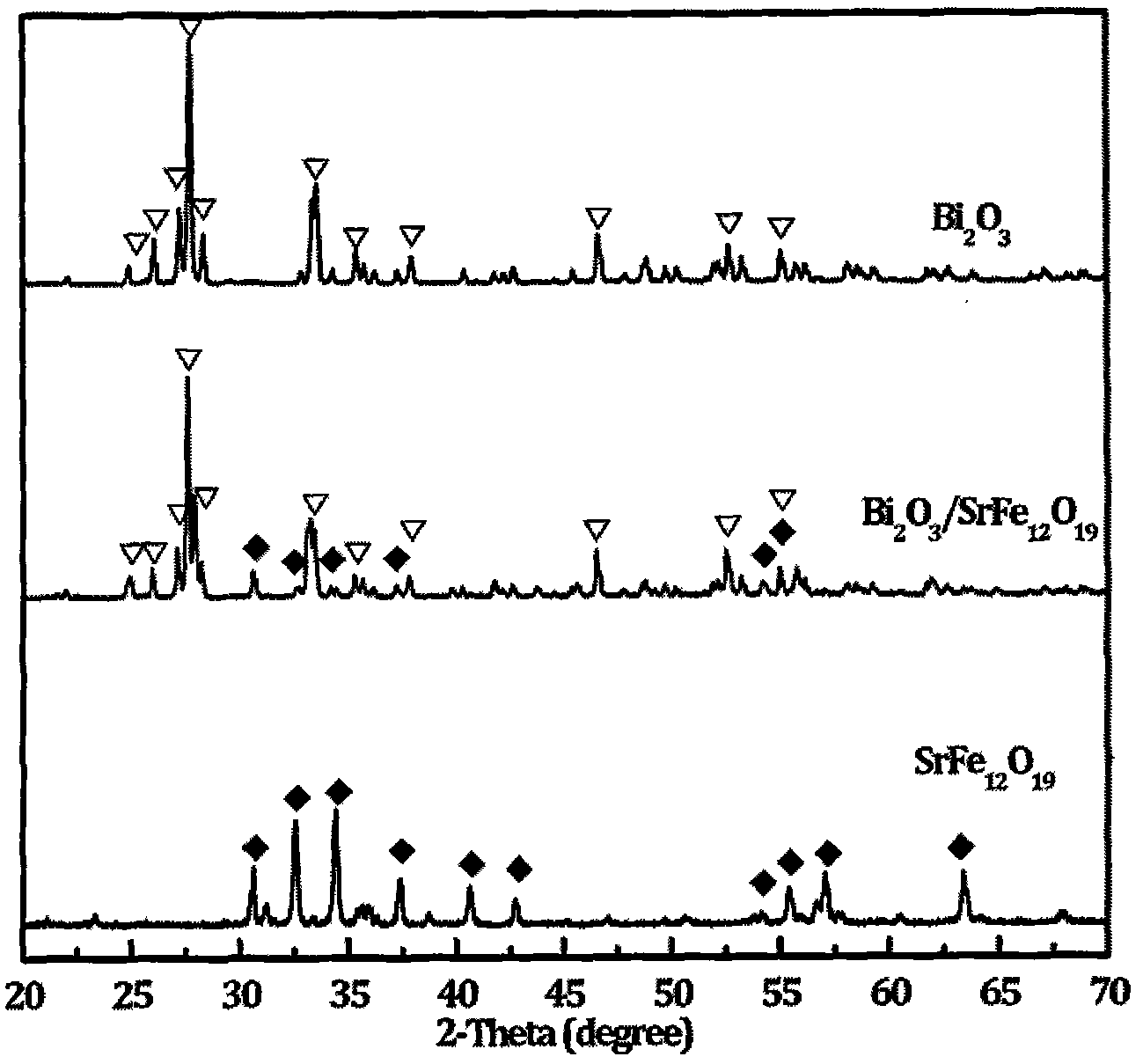

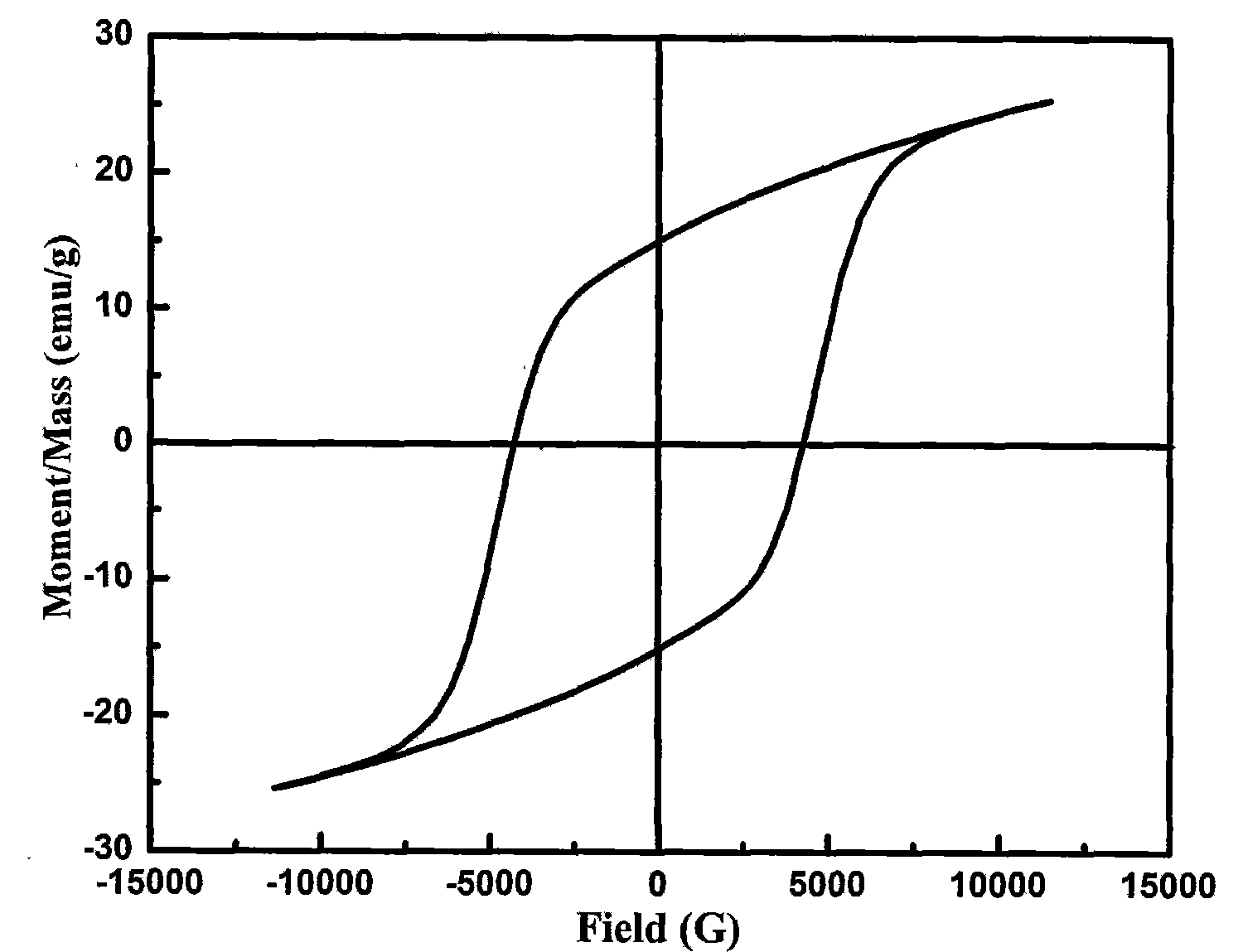

A photocatalyst and magnetic technology, which is applied in the field of preparation of bismuth-based strontium magnetic photocatalyst, can solve the problems of endangering the health of operators, low magnetization and coercivity, and easy volatility, and saves industrial production costs and magnetic properties. The effect of good degree and strong anti-demagnetization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of bismuth-based strontium magnetic photocatalyst, its specific steps are as follows:

[0024] (1) prepare bismuth nitrate homogeneous solution

[0025] Using bismuth nitrate as a raw material, using nitric acid solution as a solvent, according to the ratio of the mass (g) of bismuth nitrate: the volume (mL) of nitric acid solution with a molar concentration of 4mol / L being 1:5, add bismuth nitrate and nitric acid solution into a reaction vessel, and mechanically stirred until the bismuth nitrate was completely dissolved to prepare a transparent bismuth nitrate homogeneous solution.

[0026] (2) Preparation of strontium ferrite suspension

[0027] Using strontium ferrite as raw material, using sodium dodecylbenzenesulfonate as dispersant, according to the mass (g) ratio of sodium dodecylbenzenesulfonate, bismuth nitrate and strontium ferrite is 1:20:5 Ratio, strontium ferrite and sodium dodecylbenzenesulfonate were added into the reaction vessel, ...

Embodiment 2

[0031] A preparation method of bismuth-based strontium magnetic photocatalyst, its specific steps are as follows:

[0032] (1) prepare bismuth nitrate homogeneous solution

[0033] Using bismuth nitrate as a raw material, using nitric acid solution as a solvent, according to the ratio of the mass (g) of bismuth nitrate: the volume (mL) of the nitric acid solution with a molar concentration of 3mol / L being 1:4, add bismuth nitrate and nitric acid solution into a reaction vessel, and mechanically stirred until the bismuth nitrate was completely dissolved to prepare a transparent bismuth nitrate homogeneous solution.

[0034] (2) Preparation of strontium ferrite suspension

[0035] Using strontium ferrite as raw material, using sodium dodecylbenzenesulfonate as a dispersant, according to the mass (g) ratio of sodium dodecylbenzenesulfonate, bismuth nitrate and strontium ferrite is 1:20:4 Ratio, adding strontium ferrite and sodium dodecylbenzenesulfonate into the reaction vessel...

Embodiment 3

[0039] A preparation method of bismuth-based strontium magnetic photocatalyst, its specific steps are as follows:

[0040] (1) prepare bismuth nitrate homogeneous solution

[0041] Using bismuth nitrate as raw material, using nitric acid solution as solvent, according to the ratio of the mass (g) of bismuth nitrate: the volume (mL) of nitric acid solution with a molar concentration of 5mol / L is 1:6, add bismuth nitrate and nitric acid solution into a reaction vessel, and mechanically stirred until the bismuth nitrate was completely dissolved to prepare a transparent bismuth nitrate homogeneous solution.

[0042] (2) Preparation of strontium ferrite suspension

[0043] Using strontium ferrite as raw material, using sodium dodecylbenzenesulfonate as dispersant, according to the mass (g) ratio of sodium dodecylbenzenesulfonate, bismuth nitrate and strontium ferrite is 1:20:6 Ratio, adding strontium ferrite and sodium dodecylbenzenesulfonate into the reaction vessel, and mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com