Method for manufacturing Ag/C nano interconnecting wire in coaxial-cable structure

A technology of coaxial cables and interconnecting wires is applied in the field of preparation of Ag/C nanowires, which can solve the problems of inability to effectively control the cross-sectional shape, size and thickness of carbon coating layers of Ag nanowires, and improve the chemical reaction activity. and thermal stability, controllable cross-sectional morphology, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Ag / C nanointerconnection wires: 0.5g glucose (0.07M) and 0.2g CTAB (14mM) were dissolved in 35ml deionized water, then 1ml AgNO with a concentration of 0.1M was added 3 . Sonicate for 20 minutes to mix well. Then, the mixed solution was transferred to a 50 ml hydrothermal reactor with a filling degree of 80%, and reacted at a constant temperature of 180° C. for 6 hours. After the reaction, it was naturally cooled to room temperature. After separation by centrifugation (10000r / min), the lower precipitate was collected and washed repeatedly with deionized water and absolute ethanol. Finally, the product was placed in a nitrogen environment or vacuum, and dried at 50° C. for more than 5 hours. 6 hours, 7 hours drying is the same as 5 hours.

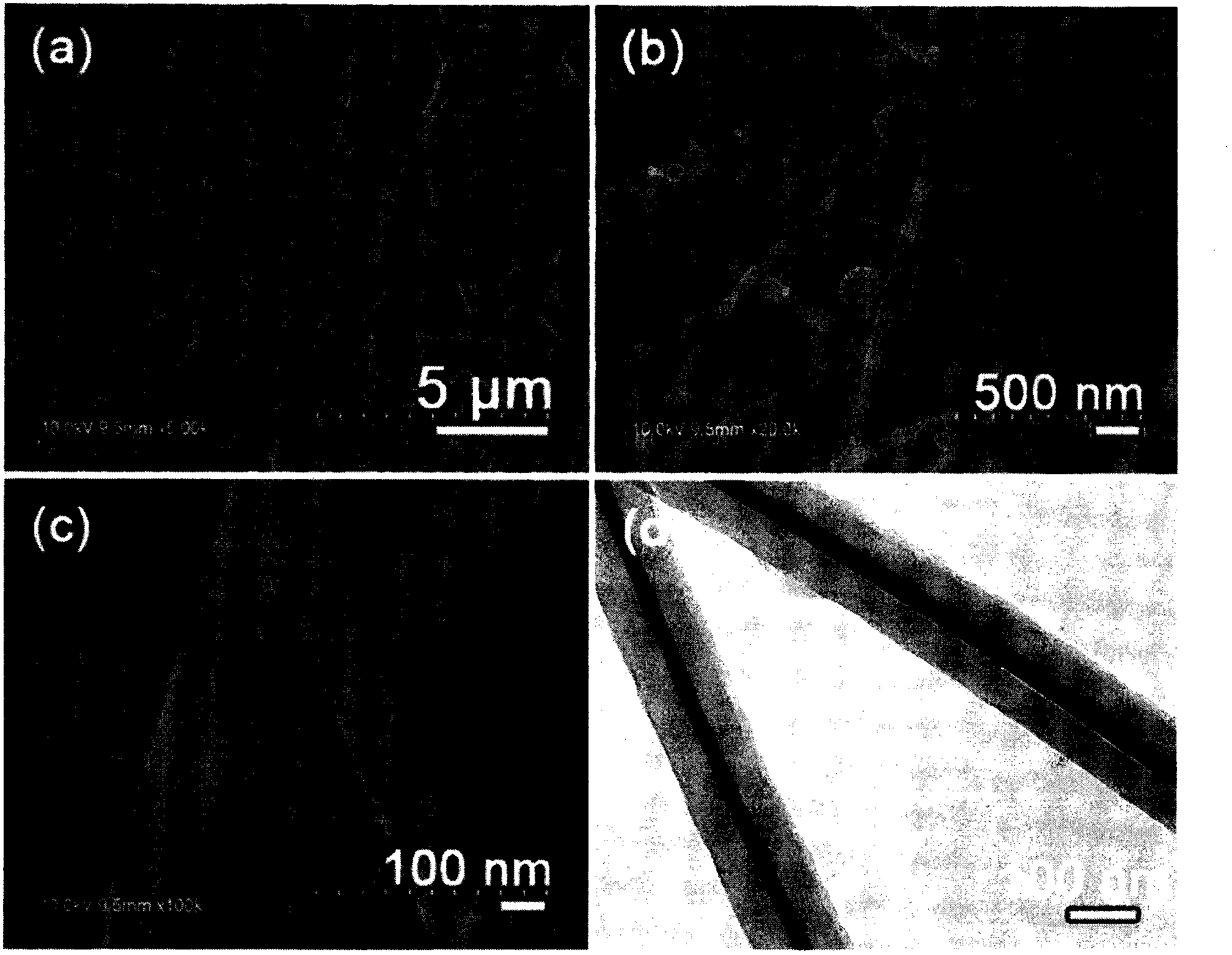

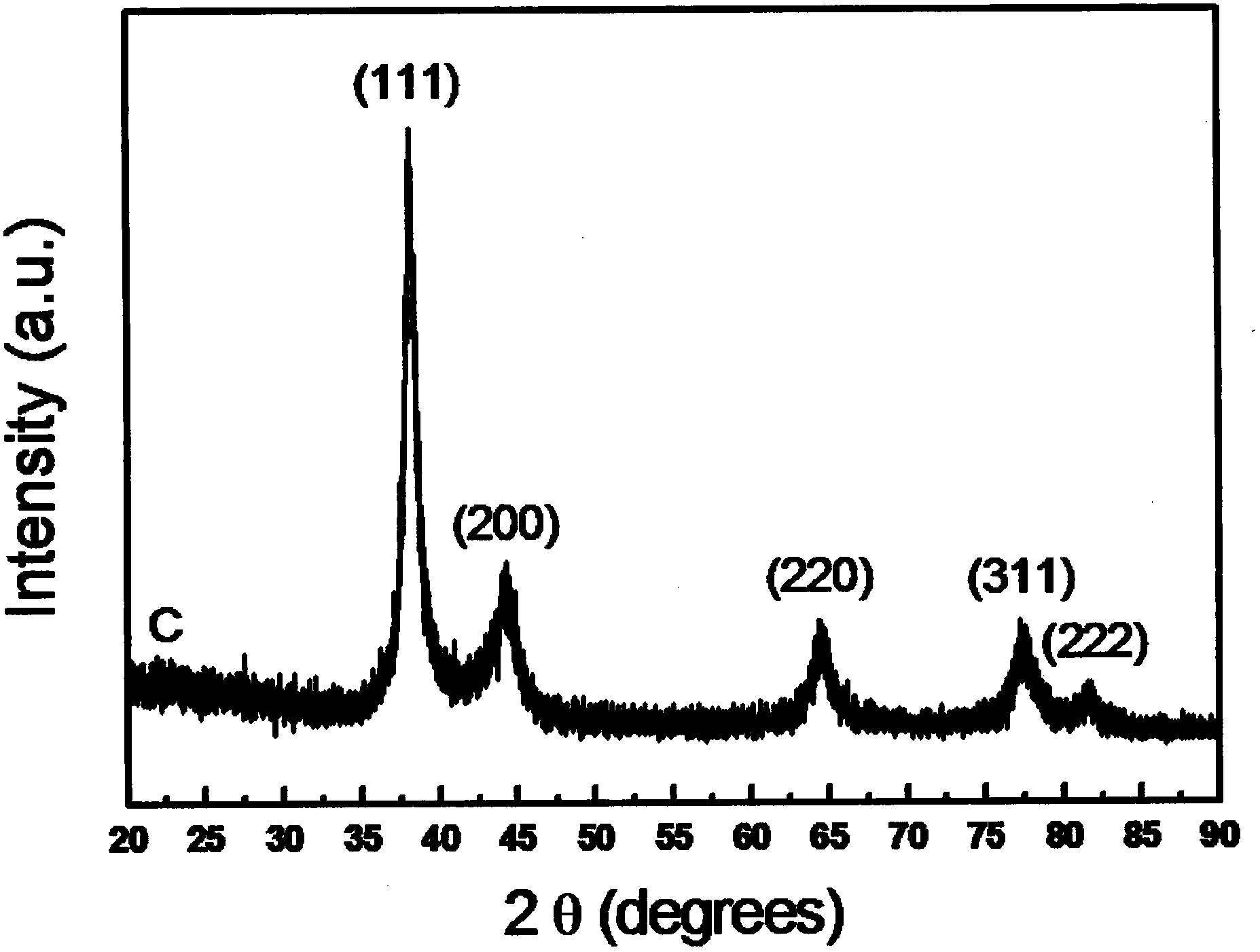

[0032] figure 1 It is the different enlarged SEM pictures of the product. It can be seen that the product is mainly composed of nanowires, the surface is very smooth, the diameter is about 165nm, the length can rea...

Embodiment 2

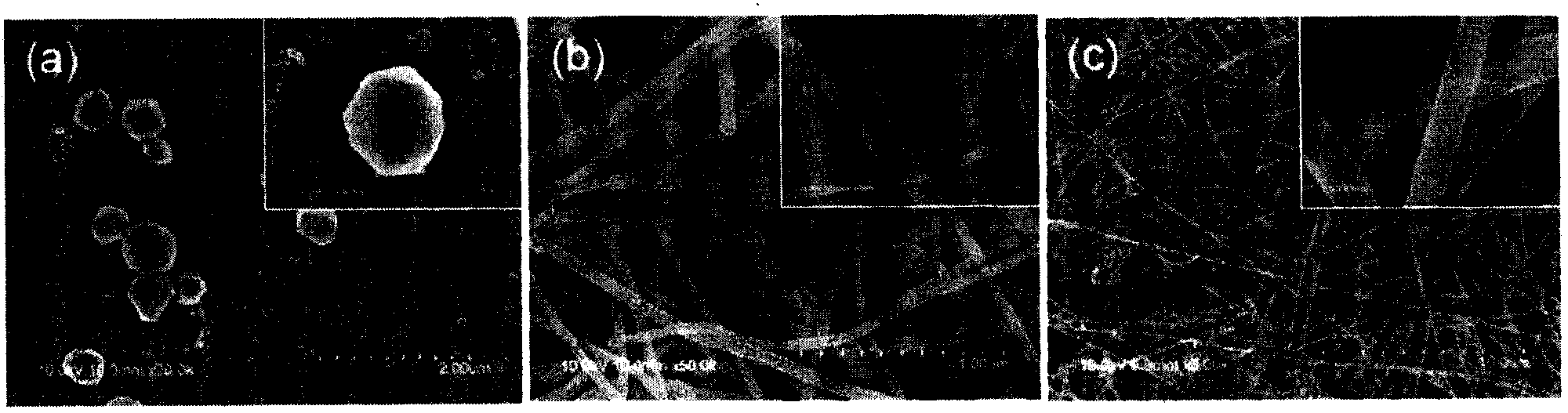

[0035] Change the CTAB concentration, the CTAB content in the reactant is 10mM, other conditions are the same as example 1.

Embodiment 3

[0037] Change CTAB concentration, CTAB content is 7mM, other conditions are the same as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com