Single-driven ultrasonic elliptical vibration turning device

A technology of elliptical vibration and ultrasonic vibration, which is applied in turning equipment, auxiliary devices, fluids using vibration, etc., can solve the problems that restrict the application and promotion of ultrasonic elliptical vibration transducers, the complex structure of ultrasonic vibration system and control system, and the influence of ultrasonic elliptical vibration. Vibration cutting effect and other problems, to achieve the effect of simplifying the control circuit and ultrasonic power supply structure, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

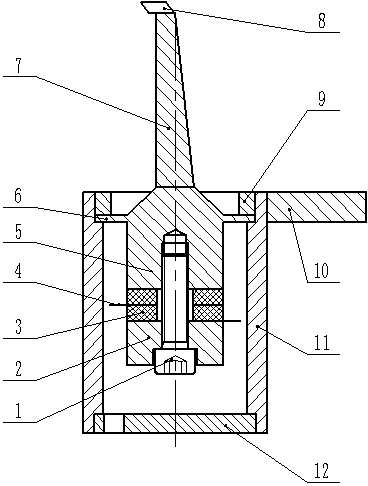

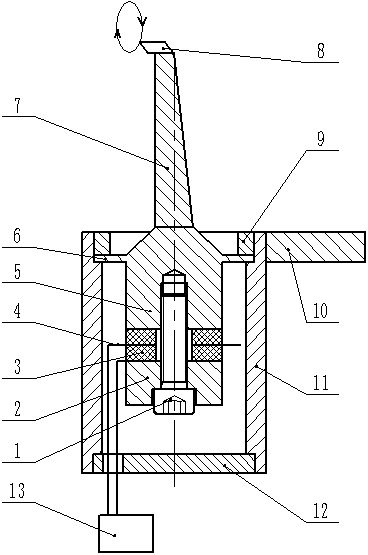

[0017] combine figure 1 , 2 As shown, the single excitation ultrasonic elliptical vibration turning device includes a housing unit, an ultrasonic vibration transducer placed in the housing unit, an elliptical vibration mode converter 7 and a tool 8 arranged at the front end of the elliptical vibration mode converter 7; The housing unit includes an upper cover plate 9, a support plate 10, an outer sleeve 11 and a lower cover plate 12. One end of the support plate 10 is welded on the outer circle of the outer sleeve 11, and the other end is fixed on the lathe tool holder to connect with the machine tool; ultrasonic vibration The outer contour of the transducer is cylindrical, which includes a bolt 1 and a rear cover 2, a piezoelectric ceramic sheet 3, an electrode sheet 4 and a front cover 5 which are sequentially sleeved on the bolt 1. The front cover 5 is provided with a The flange 6 used for the connection of the housing unit, the rear cover 2 and the front cover 5 connect a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com