Method for making completely fermented compound dragon fruit wine

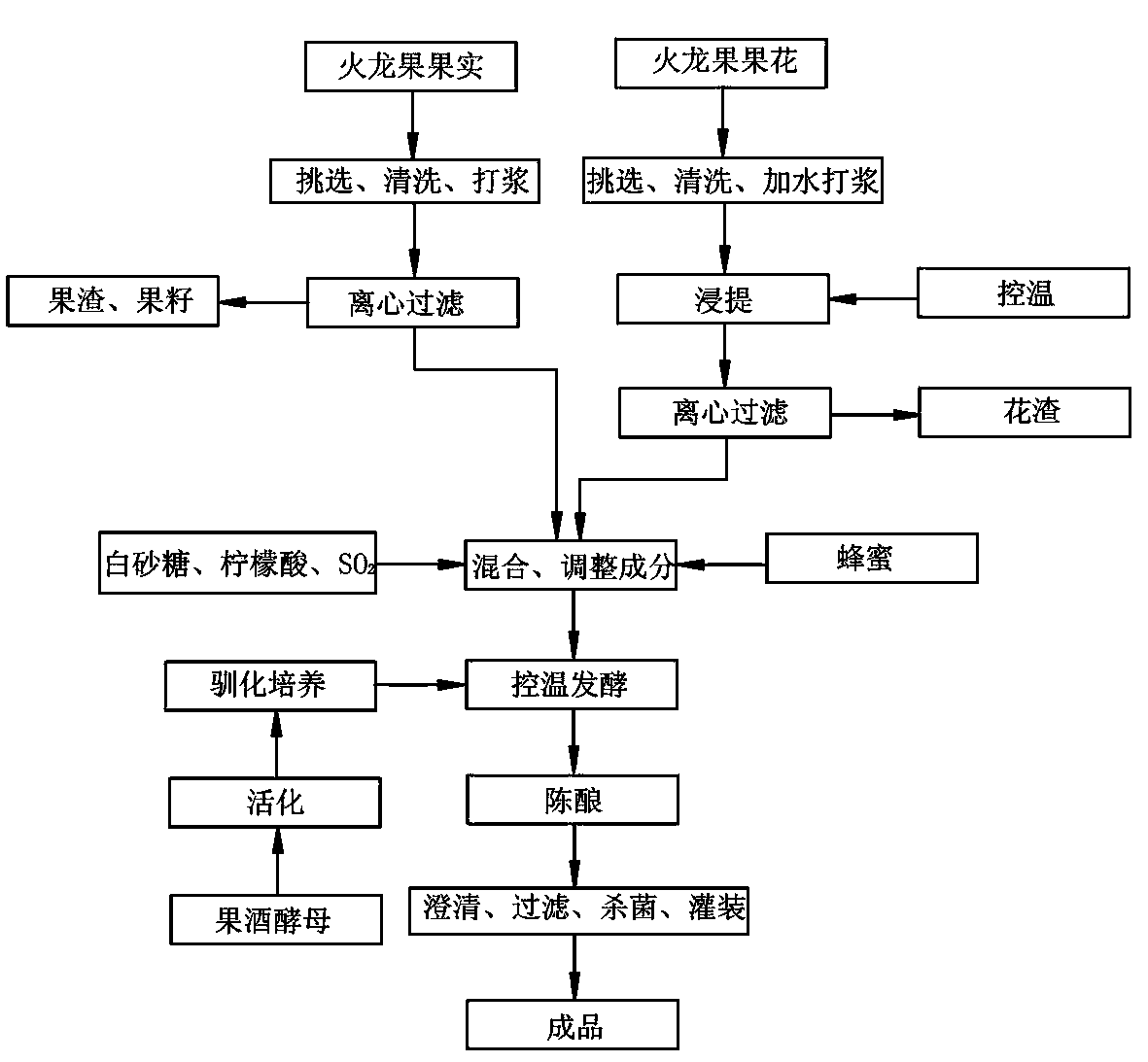

A dragon fruit and compound technology is applied in the brewing field of fully fermented compound dragon fruit wine, which can solve the problems of loss of nutrients and flavor, single processing method, and long flowering period of fruit flowers, and achieves mellow and harmonious taste and transparent color and luster. , the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, the brewing of full-fermentation compound pitaya fruit wine 1

[0024] Choose fruits and fruit flowers that are fully ripe, fresh, non-rotten, and free from diseases and insect pests, and clean them. Weigh 10Kg of fruit flowers and add 20Kg of drinking water to make a flower pulp with a beater, pump the flower pulp into a tank with a temperature control device, control the temperature at 50°C, extract at this temperature for 4 hours, and then separate it with a centrifuge Fruit flower extract juice for later use. Take by weighing 100Kg fruit, peel, beat into pulp with a beater. Use a centrifuge to filter out the fruit and pomace to obtain juice for later use. Mix the obtained fruit juice and flower juice with 4Kg of honey evenly, add 10% aqueous solution made of 30g of potassium metabisulfite, and mix well. Adjust the composition of above-mentioned mixed juice with white granulated sugar and citric acid, make the sugar content of mixed juice be 25%, PH=...

Embodiment 2

[0025] Embodiment 2, the brewing 2 of full-fermentation compound dragon fruit wine

[0026] Choose fruits and fruit flowers that are fully ripe, fresh, non-rotten, and free from diseases and insect pests, and clean them. Weigh 100Kg of fruit flower and add 250Kg of drinking water to make a flower pulp with a beater, pump the flower pulp into a tank with a temperature control device, control the temperature at 70°C, extract at this temperature for 2 hours, and then separate it with a centrifuge Fruit flower extract juice for later use. Take by weighing 1000Kg fruit, peel, beat into pulp with a beater. Use a centrifuge to filter out the fruit seeds and pomace to obtain juice for later use. Mix the obtained fruit juice and flower juice with 60Kg of honey evenly, add 10% aqueous solution made of 200g of potassium metabisulfite, and mix well. Adjust the composition of above-mentioned mixed juice with white granulated sugar and citric acid, make the sugar content of mixed juice b...

Embodiment 3

[0027] Embodiment 3, the preparation 3 of dragon fruit vinegar

[0028] Choose fruits and fruit flowers that are fully ripe, fresh, non-rotten, and free from diseases and insect pests, and clean them. Weigh 50Kg of fruit flowers and add 100Kg of drinking water to make a flower pulp with a beater, pump the flower pulp into a tank with a temperature control device, control the temperature at 60°C, extract at this temperature for 3 hours, and then separate it with a centrifuge Fruit flower extract juice for later use. Take by weighing 550Kg fruit, peel, beat into pulp with a beater. Use a centrifuge to filter out the fruit and pomace to obtain juice for later use. Mix the obtained fruit juice and flower juice with 40Kg honey evenly, add SO at 100mg / L 2 . Adjust the composition of above-mentioned mixed juice with white granulated sugar and citric acid, make the sugar content of mixed juice be 18%, PH=3.2. Pump the mixed solution of the adjusted ingredients into the fermenter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com