Premelted conductive slag for electrochemical deoxidation and preparation method thereof

A conductive slag and electrochemical technology, applied in the field of smelting and deoxidizing materials, can solve the problems of extremely high material requirements, dust pollution, non-compliance with energy saving and emission reduction, and achieve aerobic ion conductivity, easy storage and transportation, high efficiency and no emission. The effect of pollution deoxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

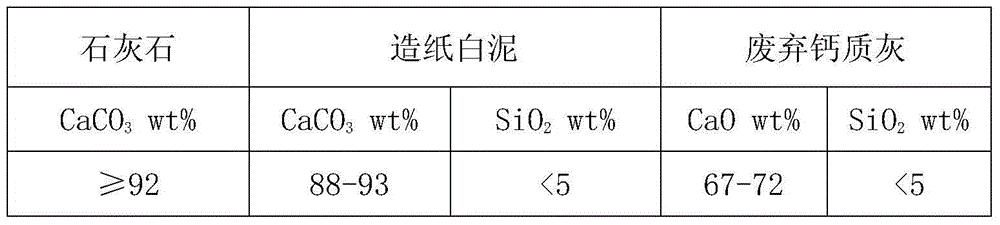

[0028] The main component of the used calcium oxide material that is rich in embodiment is shown in Table 1:

[0029] Table 1 is rich in calcium oxide material and main component list

[0030]

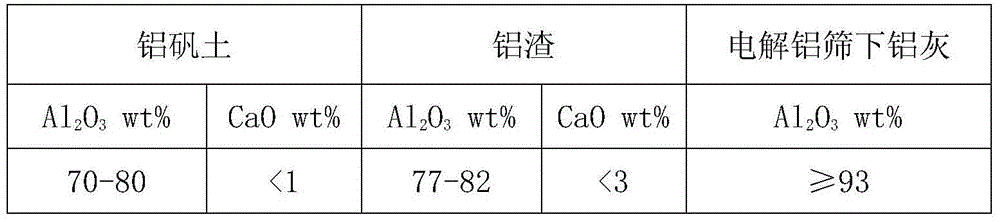

[0031] The main components of the alumina-rich material used in the embodiment are shown in Table 2:

[0032] Table 2 Alumina-rich materials and their main components

[0033]

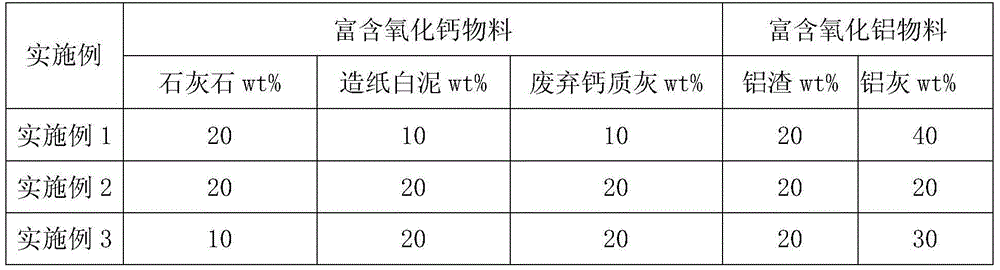

[0034] Embodiment 1,2,3 raw material proportioning are shown in Table 3:

[0035] Table 3 Raw material ratio of electrochemical deoxidation pre-melted slag

[0036]

[0037] The materials listed in Table 3 were respectively made into raw material powders below 100 mesh. The raw material powder is uniformly mixed according to the ratio of 40% to 60% of the material rich in alumina and 40% to 60% of the material rich in calcium oxide. Then put the mixed powder into a high-temperature kiln for melting at a temperature of 1400-1550°C, and cool and crystallize after melting out of the furnace. Finally,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com