Corrosion pretreatment method for zinc or tin crystal nuclei deposited on anodic oxidation of medium and high voltage electronic aluminum foil

An anodic oxidation and electronic aluminum foil technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of unseen large-scale industrial production, complicated and cumbersome process, and many control factors, and achieve the purpose of inhibiting corrosion and thinning , uniform distribution of corrosion pits, and the effect of reducing the probability of merging holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

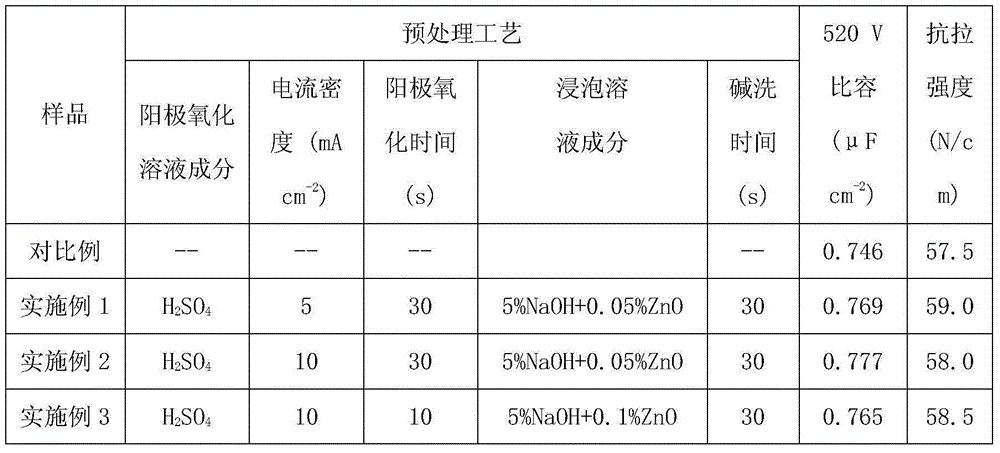

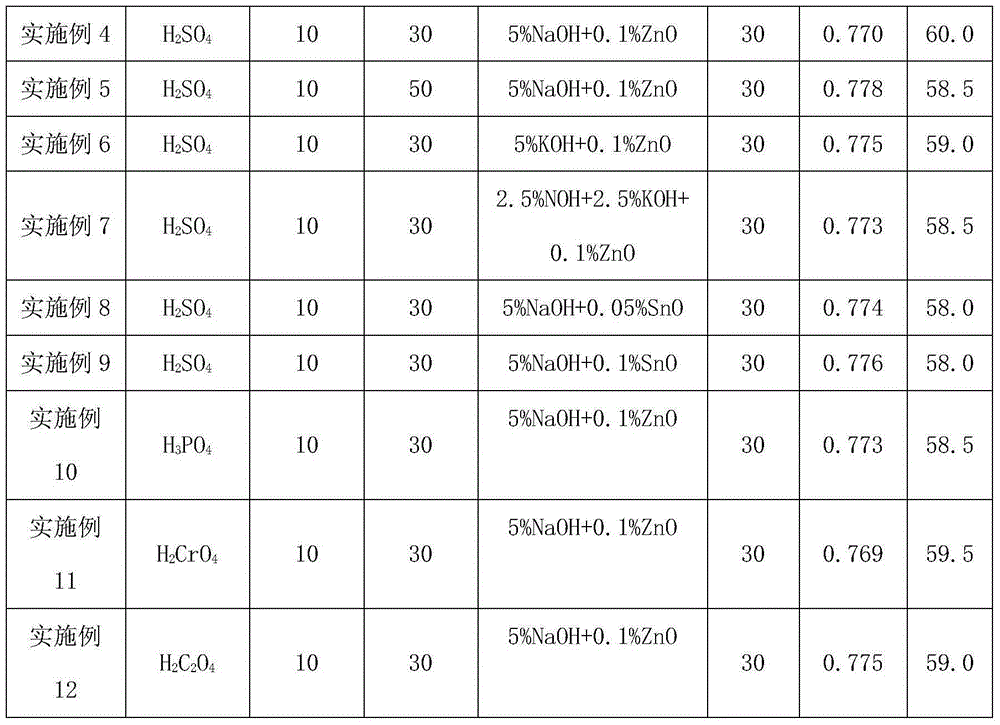

Embodiment 1

[0023] Put the aluminum foil in 20% H 2 SO 4 solution, the applied current density is 5mAcm -2 Anode current was anodized for 30s, and then the aluminum foil was immersed in a mixed solution of 5% NaOH and 0.05% ZnO at a temperature of 40°C for 30s, and then the same pitting corrosion, hole expansion corrosion, and After treatment and 520V chemical conversion treatment.

Embodiment 2

[0025] Put the aluminum foil in 20% H 2 SO 4 solution, the applied current density is 10mAcm -2 Anode current was anodized for 30s, and then the aluminum foil was immersed in a mixed solution of 5% NaOH and 0.05% ZnO at a temperature of 40°C for 30s, and then the same pitting corrosion, hole expansion corrosion, and After treatment and 520V chemical conversion treatment.

Embodiment 3

[0027] Put the aluminum foil in 20% H 2 SO 4 solution, the applied current density is 10mAcm -2 Anodic current was anodized for 10s, and then the aluminum foil was immersed in a mixed solution of 5% NaOH and 0.1% ZnO at a temperature of 40°C for 30s, and then the same pitting corrosion, hole expansion corrosion, and After treatment and 520V chemical conversion treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com