Three-dimensional multi-chip laminated module and manufacturing method thereof

A multi-chip module and chip technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of chip processing and process yield reduction and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

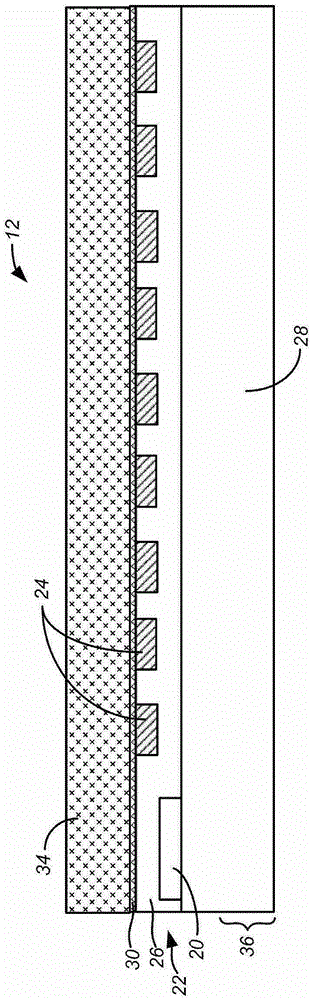

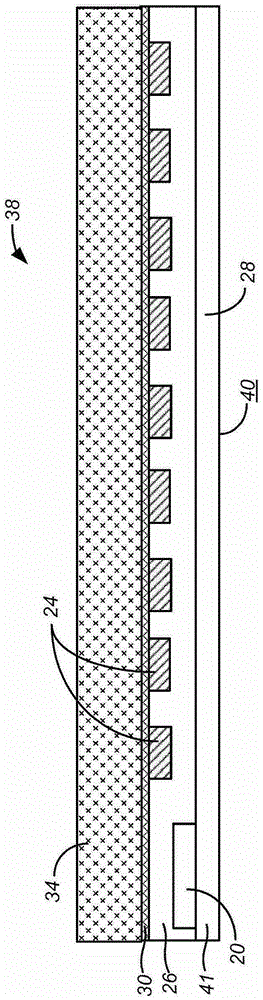

[0062] The present invention can be implemented in wafer scale stacking or diescale stacking. exist Figure 1-Figure 21 , the invention will be described in detail in terms of chip-level stacking. The advantages obtained by implementing the present invention using wafer-level stacking will be Figure 22-Figure 25 detail. Like elements in a wafer or chip will be denoted with like reference numerals.

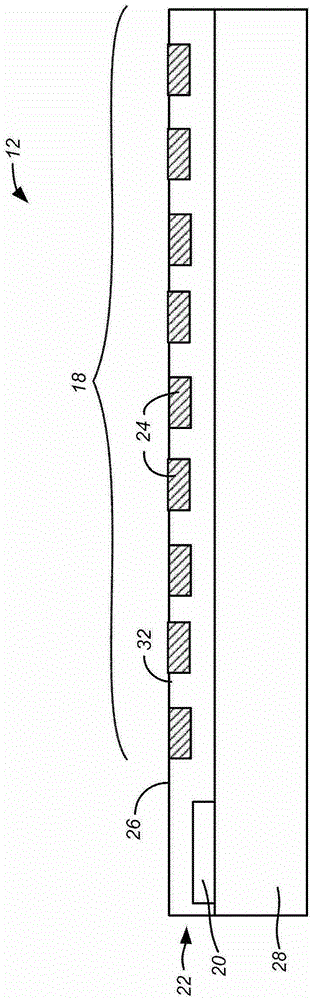

[0063] figure 1 Is a simplified enlarged cross-sectional view of an IC chip 12 suitable for building a three-dimensional stacked multi-chip module in the manner described below. figure 1 The illustrated chip 12 includes an electrical contact area 18 and an active device circuit 20 , both within a patterned conductive layer 22 . The patterned conductive layer 22 includes a dielectric layer 26 overlying and supported by a substrate 28 of the chip 12 . Substrate 28 is typically silicon. The electrical contact area 18 includes a plurality of electrical conductors 24, typically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com