Method for catalyzing inulin fructose and cassava glucose to produce high-concentration sorbitol and gluconic acid by using immobilized movement fermented monas

A technology of Zymomonas and gluconic acid, which is applied in the field of biomanufacturing and biorefining of bio-based chemicals, can solve the problems of affecting production efficiency and production cost, low concentration of sorbitol and gluconic acid, increasing costs, etc., to achieve reduction Effects of reactor usage, reduction in consumption, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

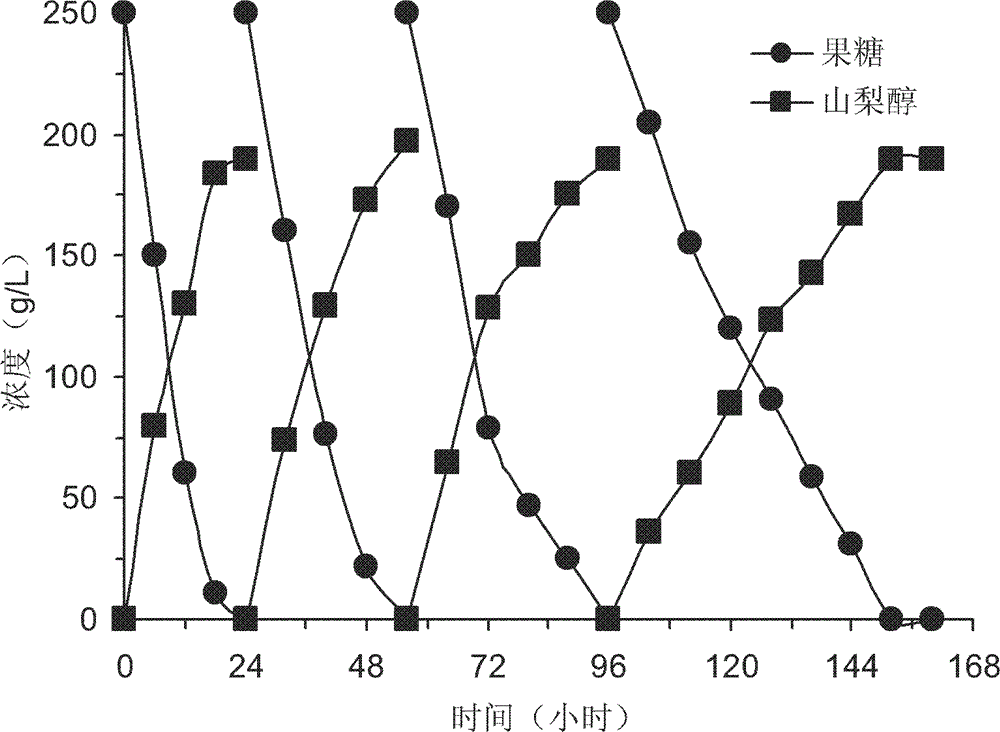

[0029] Please see attached figure 1 , after culturing Zymomonas mobilis expressing glucose-fructose oxidoreductase for 18 hours under the condition of no ventilation, 30°C, pH 6.0, 150rpm, inoculum size 10% (v / v), the wet cells were obtained by centrifugation and purified with ultrapure Water suspension to 150g / L. Then the 12.5% (w / v) PVA solution and the 0.125% (w / v) sodium alginate solution were heated and dissolved, and mixed with the cell suspension after cooling to room temperature (PVA solution and cell solution volume ratio 4:1), The mixed solution was thoroughly mixed for 1 hour under the action of magnetic stirring. Then, the mixed solution was added dropwise into a saturated boric acid solution (containing 0.3 mol / L calcium chloride) through a peristaltic pump, and stirred for 3 hours. The average diameter of the immobilized cell particles was 4 mm, and washed with a large amount of deionized water to remove the boric acid solution on the surface of the particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com