Method for manufacturing low-carbon type jellyfish fence device

A production method and technology of jellyfish fences, which are applied in textiles and papermaking, climate change adaptation, textile cables, etc., can solve the problems of jellyfish breeding loss, mesh consumption, and high cost of mesh replacement, so as to reduce the damage of breeding jellyfish and reduce the consumption of raw materials , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

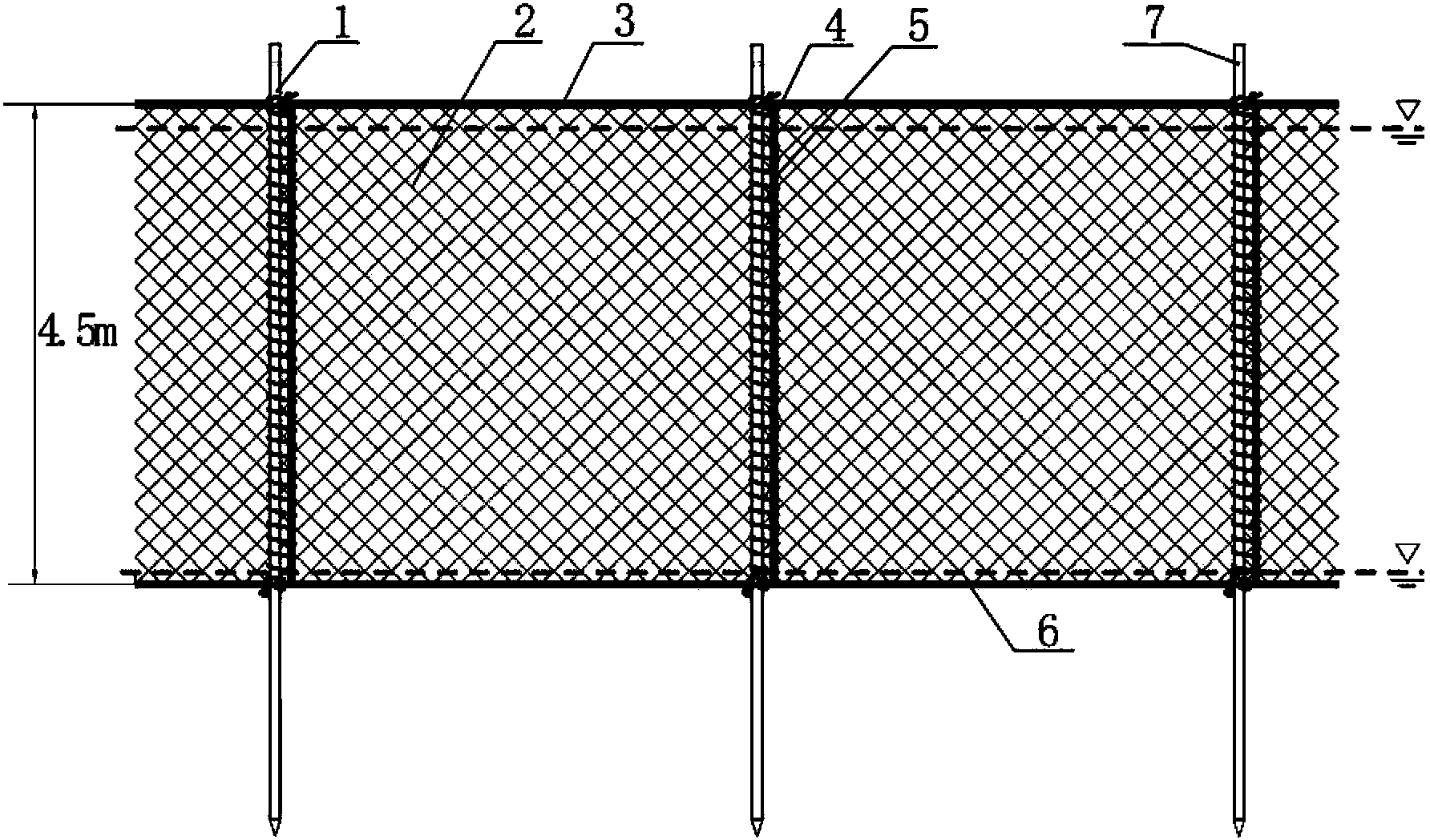

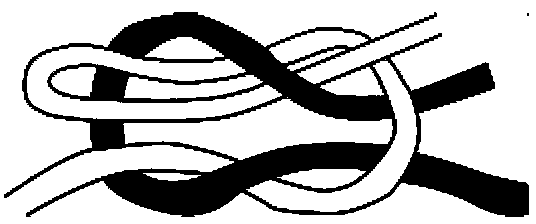

[0008] The present invention (see accompanying drawing) adopts bamboo pole, copper alloy orthorhombic net 2, high-strength polyethylene monofilament, ultra-high molecular weight polyethylene net line 5 and twelve strands of polyester rope, and earlier uses NX30 / 90 big steel order twisting machine to make 32 high-strength polyethylene monofilaments with a diameter of 0.2mm and a breaking strength of 64.4cN / tex are processed into a high-strength polyethylene monofilament rope yarn with a twist of 88T / m, and then 8 identical high-strength polyethylene monofilaments are processed in the same way Polyethylene monofilament rope yarn; then use ZG8 strand-making machine to process 3 high-strength polyethylene monofilament rope yarns into 1 high-strength polyethylene monofilament rope strand with a twist length of 15.6mm, and then process in the same way 2 identical high-strength polyethylene monofilament strands; then use ZS12 rope making machine to process 3 high-strength polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com