Compound synbiotics preparation and its application

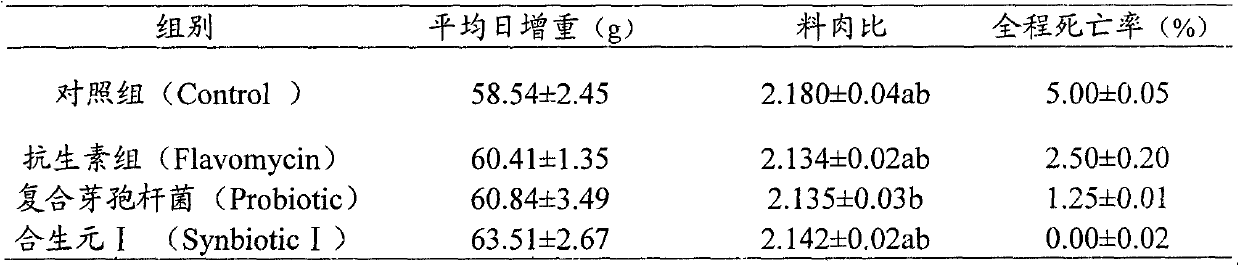

A synbiotic and compound technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of restricting the development and application of feed micro-ecological preparations, unstable quality and high bacterial rate, and achieve the enhancement of animal immunity, The effect of reducing bacteria and improving meat quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

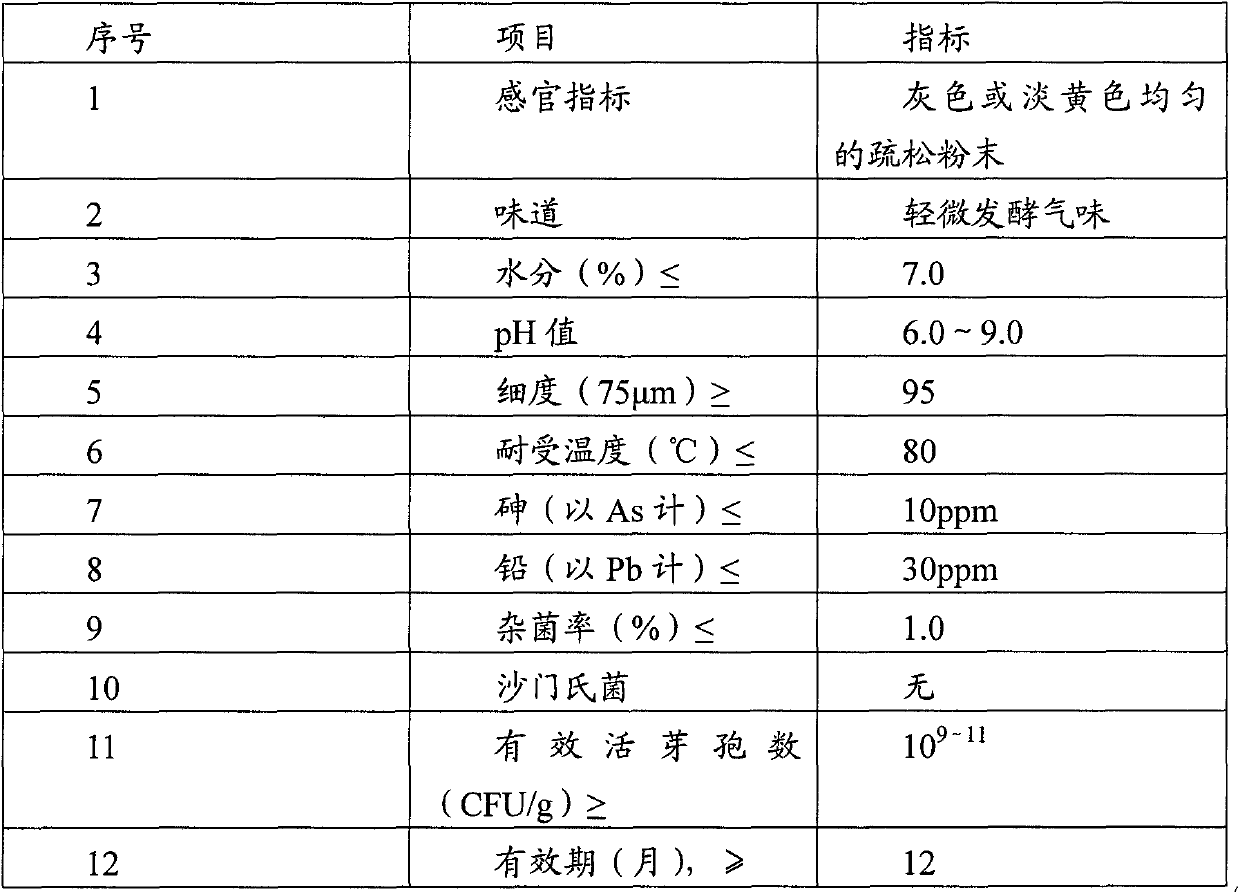

[0030] In terms of weight percentage, 40% Bacillus subtilis raw powder and 60% Bacillus licheniformis raw powder are mixed evenly to obtain compound probiotics, wherein the number of live spores of Bacillus subtilis raw powder is more than 1 trillion / g, and the raw Bacillus licheniformis powder is live The number of spores is ≥500 billion / g, and the total number of spores after mixing into compound probiotics is 1.0×10 9 ~1.0×10 11 CFU / g;

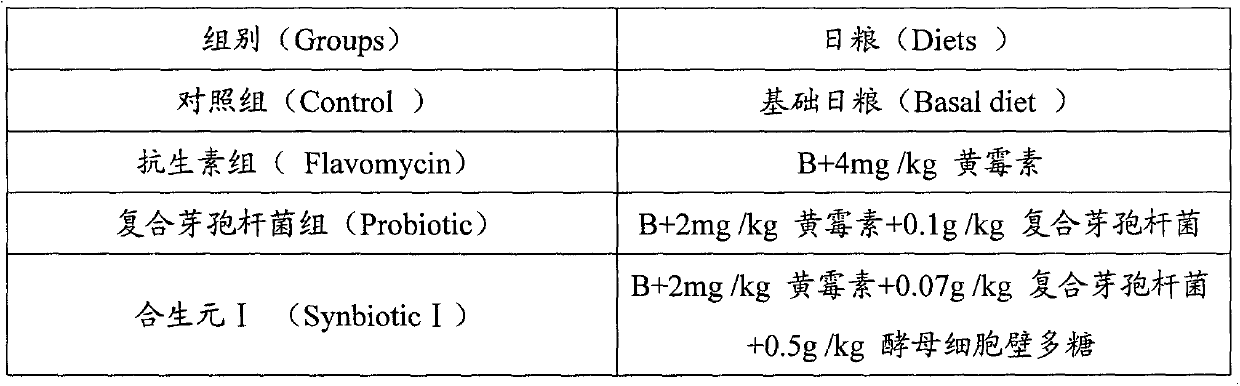

[0031] Prebiotics are selected as yeast cell wall polysaccharides, wherein 35 parts of the above-mentioned compound probiotics and 65 parts of prebiotics are uniformly mixed by weight percentage to prepare a compound synbiotic preparation.

[0032] The above-mentioned compound synbiotic preparation is added to the drinking water at a mass fraction of 0.05% to 0.2%, and the animals are allowed to drink freely. Juvenile animals can be appropriately thicker.

Embodiment 2

[0034]In terms of percentage by weight, select 45% Bacillus subtillus (Bacillus subtillus, strain preservation number: CCTCC NO.M209317) and 55% Bacillus licheniformis subsp.Licheniformis, strain preservation number: CCTCC NO.M208251 ) mixed evenly to obtain compound probiotics, wherein the number of live spores of the original powder of Bacillus subtilis ≥ 1 trillion / g, and the number of live spores of the original powder of Bacillus licheniformis ≥ 500 billion / g (the preparation processes of Bacillus subtilis and Bacillus licheniformis were respectively adopted by Wuhan Science and Technology Co., Ltd. Nuo Biotechnology Co., Ltd. independent patent: ZL201010147918.0 and ZL200910063822.3), the total number of spores after mixing into compound probiotics is 1.0×10 9 ~1.0×10 11 CFU / g;

[0035] The prebiotics were selected as mannan oligosaccharides, wherein 20 parts of the above-mentioned compound probiotics and 65 parts of prebiotics were uniformly mixed to prepare a compound...

Embodiment 3

[0038] In terms of weight percentage, select 50% Bacillus subtilis original powder (Bacillus subtillus, strain preservation number: CCTCC NO.M209317) and 50% Bacillus licheniformis subsp.Licheniformis, strain preservation number: CCTCC NO.M208251 ) mixed evenly to obtain compound probiotics, wherein the number of live spores of the original powder of Bacillus subtilis reached 1 trillion / g, and the number of live spores of the original powder of Bacillus licheniformis reached 500 billion / g (the preparation processes of Bacillus subtilis and Bacillus licheniformis were respectively adopted by Wuhan Science and Technology Co., Ltd. Nuo Biotechnology Co., Ltd. independent patent: ZL201010147918.0 and ZL200910063822.3), the total number of spores after mixing into compound probiotics is 1.0×10 9 ~1.0×10 11 CFU / g;

[0039] Prebiotics are selected as yeast cell wall polysaccharides, wherein 10 parts of the above-mentioned compound probiotics and 70 parts of prebiotics are evenly mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com