Method for improving use value of inferior tobacco leaves with subcritical dry cleaning technology

A subcritical and tobacco leaf technology, applied in the direction of tobacco, application, and treatment of tobacco, to achieve broad development prospects, increase utilization rate, and reduce residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

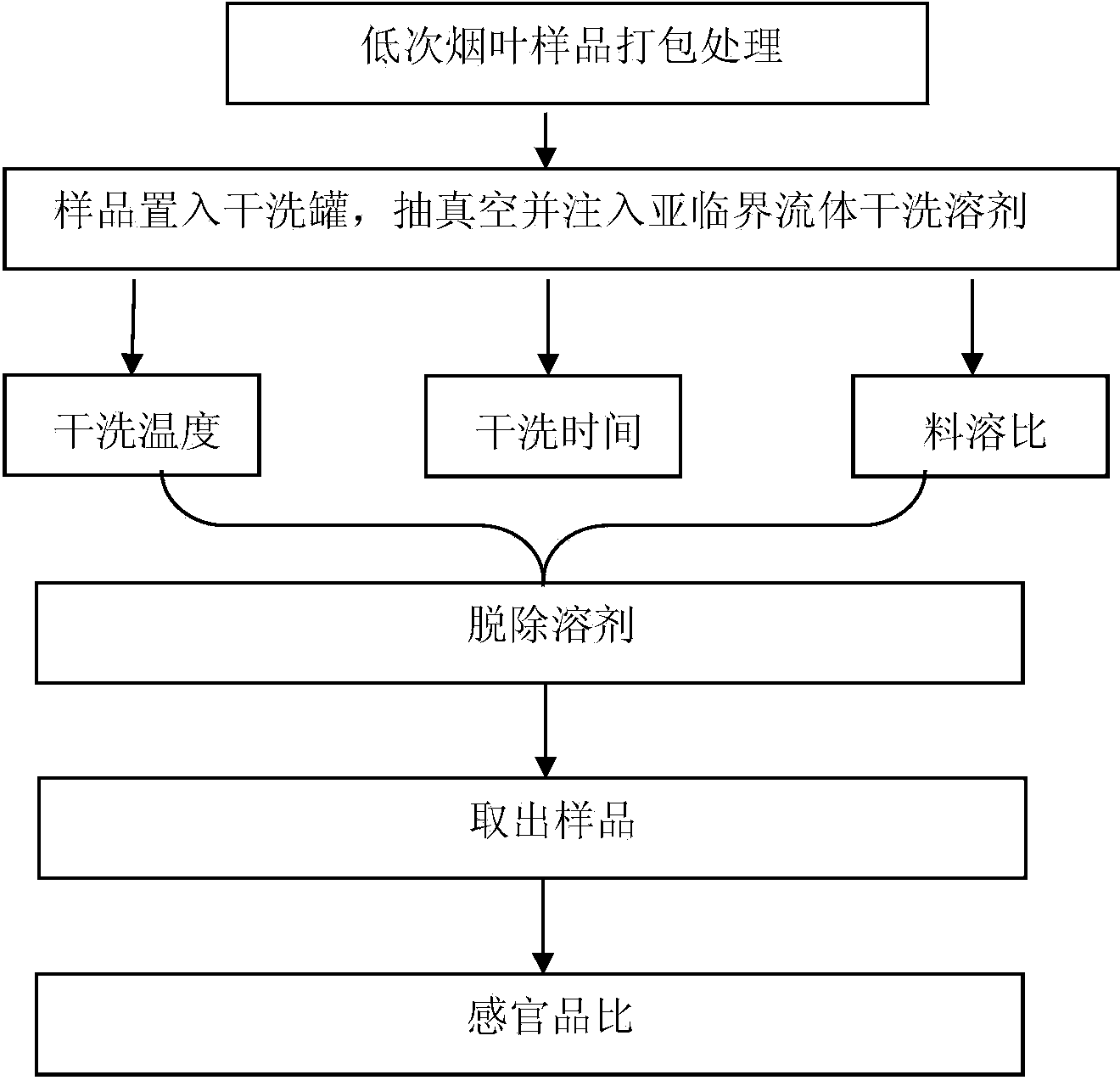

Method used

Image

Examples

Embodiment 1

[0021] Take 500g of a low-grade tobacco leaf formula module tobacco leaf raw material, pack it under the condition of ensuring the appearance, and place it in a closed dry cleaning tank as a whole. After closing the feeding channel, vacuumize, inject liquid propane solvent, and completely immerse the finished tobacco leaf ; The material-solvent ratio is 1:3, the dry cleaning time is 10 minutes, the temperature is 30°C, and the pressure is 0.29MPa; after the dry cleaning, the liquid solvent is pumped into the evaporation tank, and the sample and the liquid solvent are desolvated separately. The solvent gas evaporated from the low-smoke sample and the liquid solvent is compressed and liquefied by the diaphragm compressor, and the liquid solvent flows back to the solvent circulation tank for recycling. After the treatment, the appearance and shape of the tobacco leaves remained good, and the harmful components were all reduced to varying degrees. The ratio of sensory products aft...

Embodiment 2

[0023] Take 200g of blended Henan BK31 low-grade tobacco leaves, pack them under the condition of ensuring the shape, put them in a closed dry-cleaning tank as a whole, inject liquid butane solvent, and completely immerse the finished tobacco leaves; the material-solvent ratio is 1:4, dry-clean The time is 5 minutes, the temperature is 25° C., and the pressure is 0.25 MPa; after the dry cleaning is completed, the solvent is removed according to the method in Example 1, and the sample is taken out. The comparison of sensory products after treatment shows that compared with the control sample, the characteristics of sweetness and aroma are improved, the aroma quality is better, delicate, slightly stronger, less irritating, and the aftertaste is clean and comfortable.

Embodiment 3

[0025] Take 500g of mixed C1B1 low-grade tobacco leaves from the Baiyun warehouse in Guizhou, pack them under the condition of ensuring the shape, place the whole in a closed dry-cleaning tank, inject liquid dimethyl ether solvent, and completely immerse the finished tobacco leaves; the ratio of material to solution is 1: 5. The dry cleaning time is 10 minutes, the temperature is 10° C., and the pressure is 0.36 MPa; after the dry cleaning is completed, the solvent is removed according to the method in Example 1, and the sample is taken out. The ratio of sensory products after treatment shows that compared with the control, the sample has better combustion characteristics, the woodiness and throat dryness are reduced, the richness and fineness are improved, and the aroma volume is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com