Constraint bed adsorption separation technology and method

A separation technology and bed adsorption technology, applied in the new separation field, can solve the problems of high price, collapse of the expanding bed, limiting the wide application of EBA technology, etc., and achieve the effect of low cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

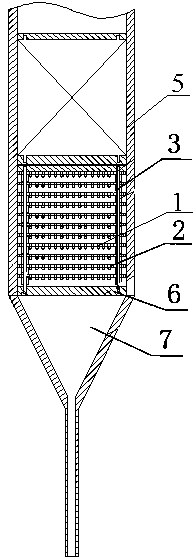

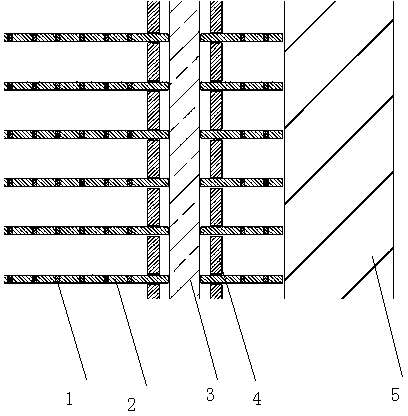

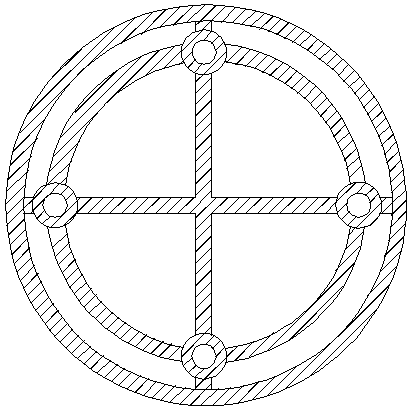

Embodiment 1

[0055] The inner diameter of the confined bed column is 24 mm, the outer diameter is 30 mm, and the height is 1000 mm (the experimental device can adjust the column height to 200 mm) ~ 900 mm); the superparamagnetic magnetic adsorbent (adsorbent) particle size is 600-700 microns, and the active group is carboxyl. Construct a "constrained bedpost" column according to the magnetically hard confinement scheme. The fluids are deionized water, 10% and 20% glycerol-deionized aqueous solution by mass ratio. The results show that the axial mixing coefficients of fluids with different viscosities and flow velocities in column beds of different heights are between 1~9×10 -6 m 2∕s Between, the fluid is close to plug flow. The lower distributor was loaded with or without 4mm glass beads with similar results.

Embodiment 2

[0057] The inner diameter of the confined bed column is 50 mm, the outer diameter is 58 mm, and the height is 1000 mm (the experimental device can adjust the column height to 200 mm) ~ 900 mm); the fluids are deionized water, 10% and 20% glycerol-deionized aqueous solution by mass ratio; the structured adsorbent is self-made agarose DEAE ion exchanger (adsorbent). Construct a "constrained bed column" column according to the hard confinement scheme of regularized adsorbent. The results show that the axial mixing coefficients of fluids with different viscosities and flow velocities in column beds of different heights are between 1~9×10 -6 m 2 ∕s Between, the fluid is close to plug flow. The lower distributor was loaded with or without 4mm glass beads with similar results.

Embodiment 3

[0059] The inner diameter of the confined bed column is 50 mm, the outer diameter is 58 mm, and the height is 1000 mm (the experimental device can adjust the column height to 200 mm) ~ 900 mm); the adsorbent is DK110 resin (adsorbent), with a particle size of 1500-2000 microns. The fluids are deionized water, 10% and 20% glycerol-deionized aqueous solution by mass ratio. Construct a "constrained bed column" column according to the hard confinement scheme of regularized adsorbent. The results show that the axial mixing coefficients of fluids with different viscosities and flow velocities in column beds of different heights are between 1~9×10 -6 m 2 ∕s Between, the fluid is close to plug flow. The lower distributor was loaded with or without 4mm glass beads with similar results.

[0060] The beneficial effects of the present invention are: the confined bed adsorption separation technology can directly extract the target components from the particle-containing material lik...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com