Composite soil adsorbent for preventing high-content soil in concrete from adsorbing poly-carboxylic water reducer, and preparation method and using method of composite soil adsorbent

An adsorbent and concrete technology, applied in the fields of the preparation of the composite soil adsorbent, concrete admixture, and composite soil adsorbent, can solve the problems of reduced adsorption, poor performance of polycarboxylate water reducer, etc., and achieves reduced adsorption , conducive to large-scale production, good water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

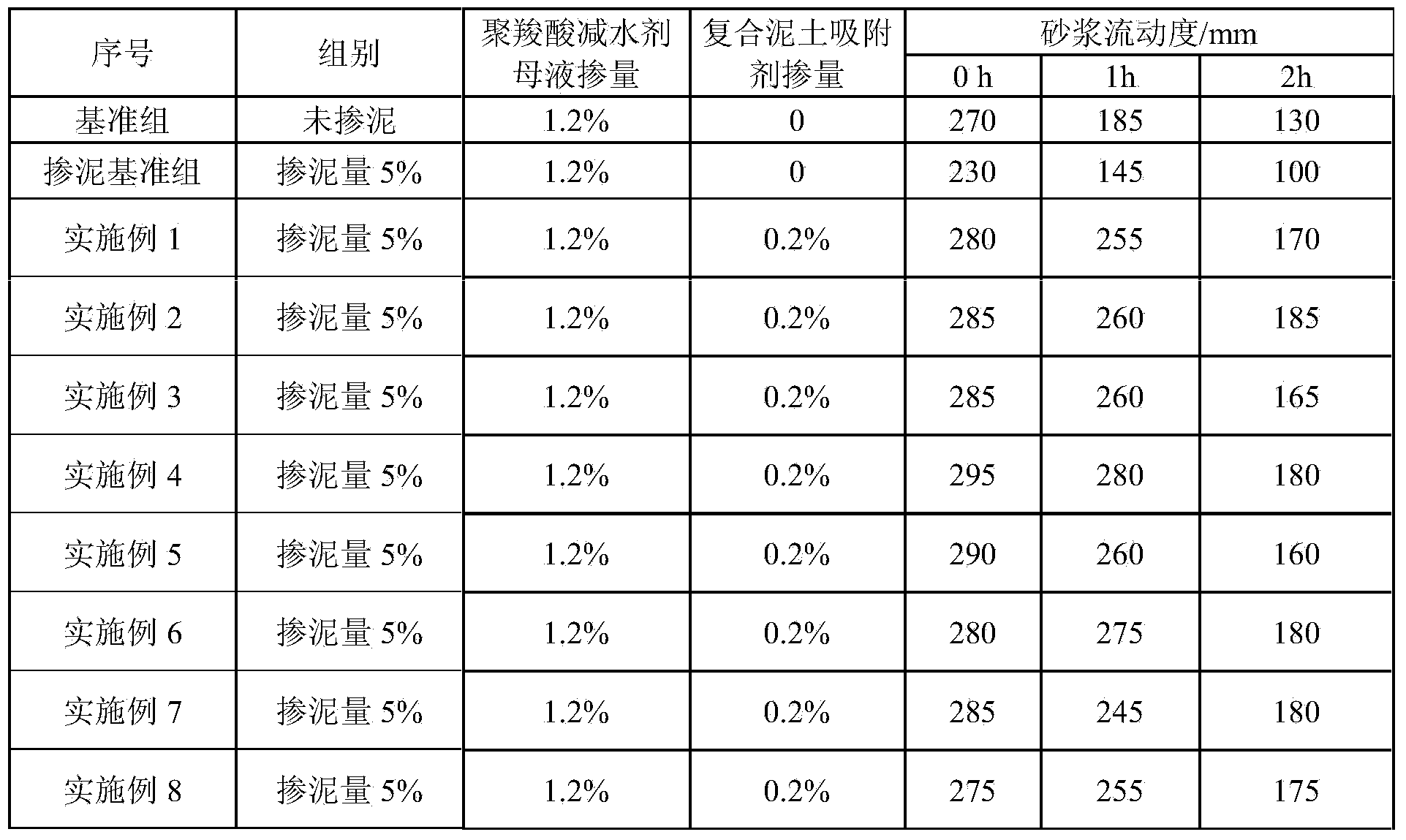

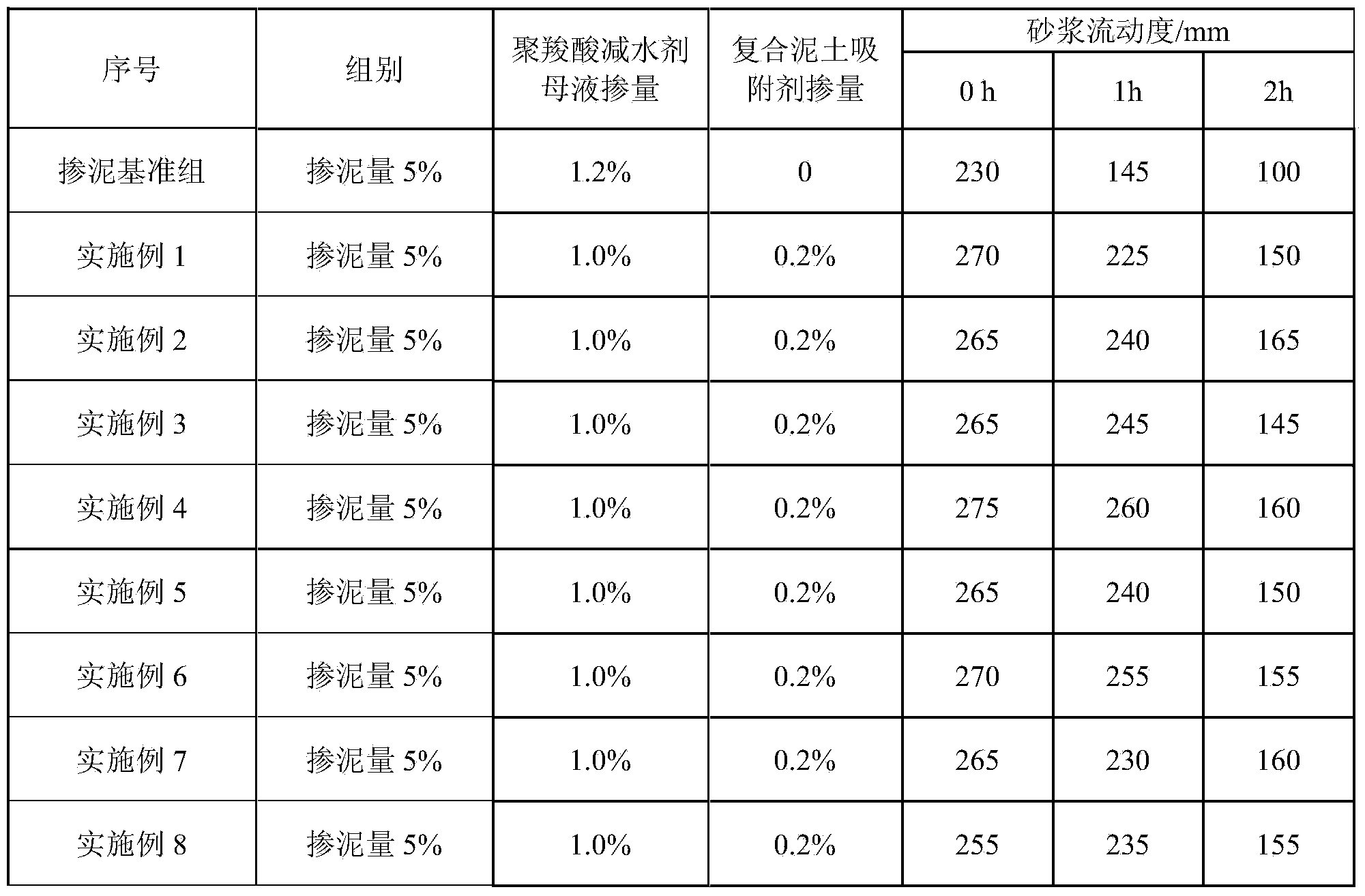

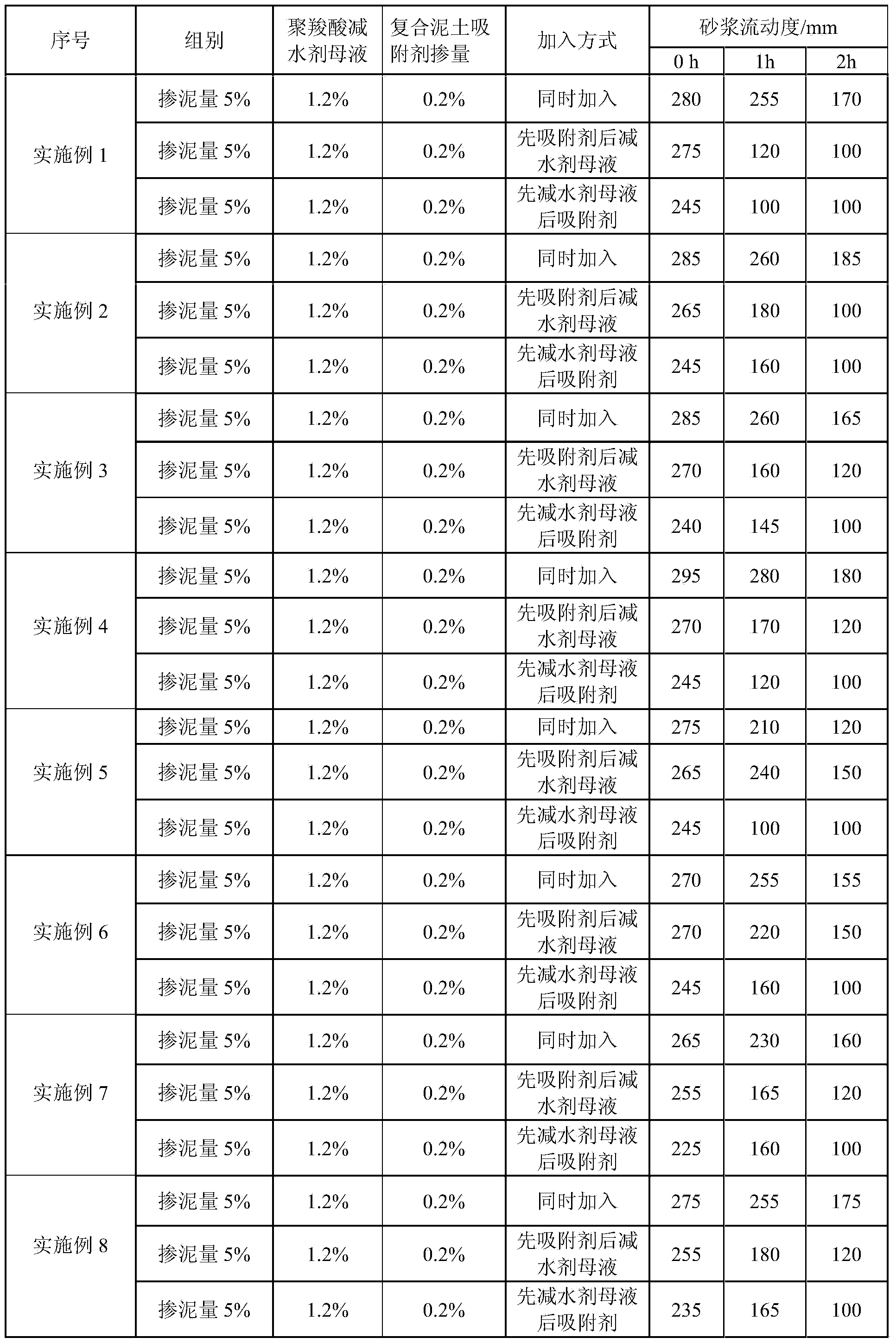

Examples

Embodiment 1

[0020] Embodiment 1 (can be in laboratory state): composite soil adsorbent of the present invention is to be made by the raw material of following mass percentage ratio: sodium tripolyphosphate 15%, sodium phosphate 5%, sodium citrate 5%, Aminotrimethylene phosphonic acid 1.5%, cetyltrimethylammonium bromide 0.5%, water 73%.

[0021] The preparation method of the composite soil adsorbent of the present invention comprises the following steps: ①According to the ratio of the above-mentioned raw materials, first add sodium tripolyphosphate and sodium phosphate into the reaction kettle, then add water into the reaction kettle, and stir evenly until the tripolyphosphate Sodium phosphate and sodium phosphate are completely dissolved to obtain a uniform solution; ②Then add sodium citrate and aminotrimethylene phosphonic acid into the solution according to the ratio of the above raw materials, and stir until it is completely dissolved in the solution; ③Finally, according to the above r...

Embodiment 2

[0022] Embodiment 2 (can be in the laboratory state): composite soil adsorbent of the present invention is to be made from the raw material of following mass percentage ratio: sodium phosphate 10%, sodium silicate 5%, sodium carbonate 5%, citric acid Sodium 5%, hydroxyethylidene diphosphonic acid 2.5%, dodecyldimethylbenzyl ammonium bromide 0.5%, water 72%.

[0023] The preparation method of composite soil adsorbent of the present invention comprises the following steps: 1. according to the proportioning of above-mentioned raw materials, sodium phosphate, sodium silicate, sodium carbonate are first added in the reactor, then add water in the reactor, stir until Dissolve sodium phosphate, sodium silicate, and sodium carbonate completely to obtain a uniform solution; ② then add sodium citrate and hydroxyethylidene diphosphonic acid into the solution according to the ratio of the above raw materials, and stir until it is completely dissolved in the solution; ③ Finally, add dodecyld...

Embodiment 3

[0024] Embodiment 3 (can be in the laboratory state): composite soil adsorbent of the present invention is to be made by the raw material of following mass percentage ratio: sodium tripolyphosphate 10%, sodium phosphate 5%, sodium humate 5%, Sodium gluconate 5%, aminotrimethylene phosphonic acid 2.5%, dodecyldimethylbenzyl ammonium bromide 0.5%, water 72%.

[0025] The preparation method of the composite soil adsorbent of the present invention comprises the following steps: ①according to the ratio of the above-mentioned raw materials, sodium tripolyphosphate, sodium phosphate, and sodium humate are first added to the reaction kettle, and then water is added in the reaction kettle, and stirred Uniformly until sodium tripolyphosphate, sodium phosphate, and sodium humate are completely dissolved to obtain a uniform solution; ② Then add sodium gluconate and aminotrimethylene phosphonic acid into the solution according to the ratio of the above raw materials, and stir until it is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com