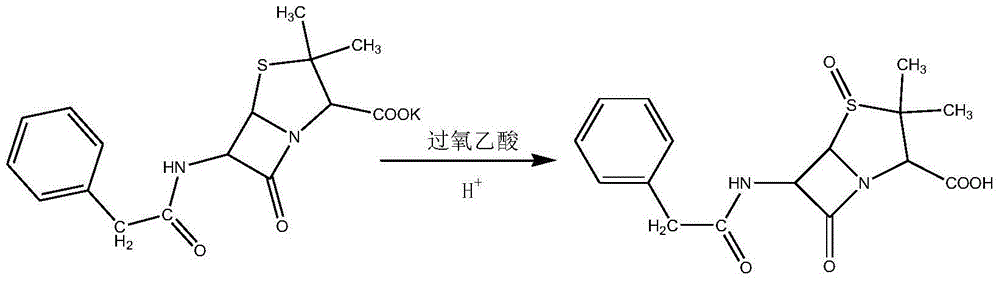

Method for preparing cephalosporin midbody penicillin sulfoxide

A penicillin sulfoxide and intermediate technology, applied in the field of preparation of cephalosporin intermediate penicillin sulfoxide, can solve the problems of increasing the use and recovery of solvents, reducing the yield of final products, and increasing production steps, so as to reduce drying steps and reduce Effects of energy consumption and improvement of production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a. Take 1000ml of butyl acetate extract (BA solution) of penicillin fermentation broth with a potency of 90,000-120,000 units / ml, control the temperature at 5-10°C, and adjust the pH to 6.5-6.8 with 8% potassium carbonate aqueous solution , stirring and extracting for 30 min, and phase separation to obtain an aqueous solution of penicillin potassium salt, controlling the concentration of penicillin potassium salt to 225 mg / ml.

[0028] b. Add activated carbon with 3% weight of penicillin potassium salt, vacuumize not lower than -0.095Mpa, stir for 60min for decolorization and deesterification, and filter with suction. filtrate 30mm×300mm alumina column, choose 100 mesh basic alumina filler, collect the column liquid within 30min, then wash the column with deionized water, and merge the washing liquid into the column liquid.

[0029] c. Cool down to 3°C, add dropwise 30% peracetic acid solution for oxidation, the amount of peracetic acid used is 1.10 times the number o...

Embodiment 2

[0032] The difference from Example 1 is that the salt solution used for extraction in step a is sodium carbonate aqueous solution, and the packing of the alumina column in step b is 120 mesh basic alumina. In this example, the yield from penicillin fermentation extract to penicillin sulfoxide was 86.6%.

Embodiment 3

[0034] a. Take 1000ml of BA solution with a potency of 80,000-100,000 units / ml, control the temperature at 5-10°C, adjust the pH to 7.0-7.2 with 5% potassium carbonate aqueous solution, stir and extract for 30 minutes, and separate phases to obtain penicillin potassium salt Aqueous solution, control penicillin potassium salt concentration 220mg / ml.

[0035] b. Add activated carbon with 3% weight of penicillin potassium salt, vacuumize not lower than -0.095Mpa, stir for 60min for decolorization and deesterification, and filter with suction. filtrate 30mm×450mm alumina column, choose 120 mesh neutral alumina filler, collect the column liquid within 30min, then wash the column with an appropriate amount of deionized water, and merge the washing liquid into the column liquid.

[0036] c. Cool down to 5°C, add dropwise 30% peracetic acid solution for oxidation, the amount of peracetic acid used is 1.10 times the molar number of penicillin, and add in 30-60 minutes. Then within 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com