Condensed type die silicone rubber and preparation method thereof

A silicone rubber, condensation-type technology, applied in the field of silicone rubber preparation, can solve the problems of poor resistance to medium and high temperatures, slow finger drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

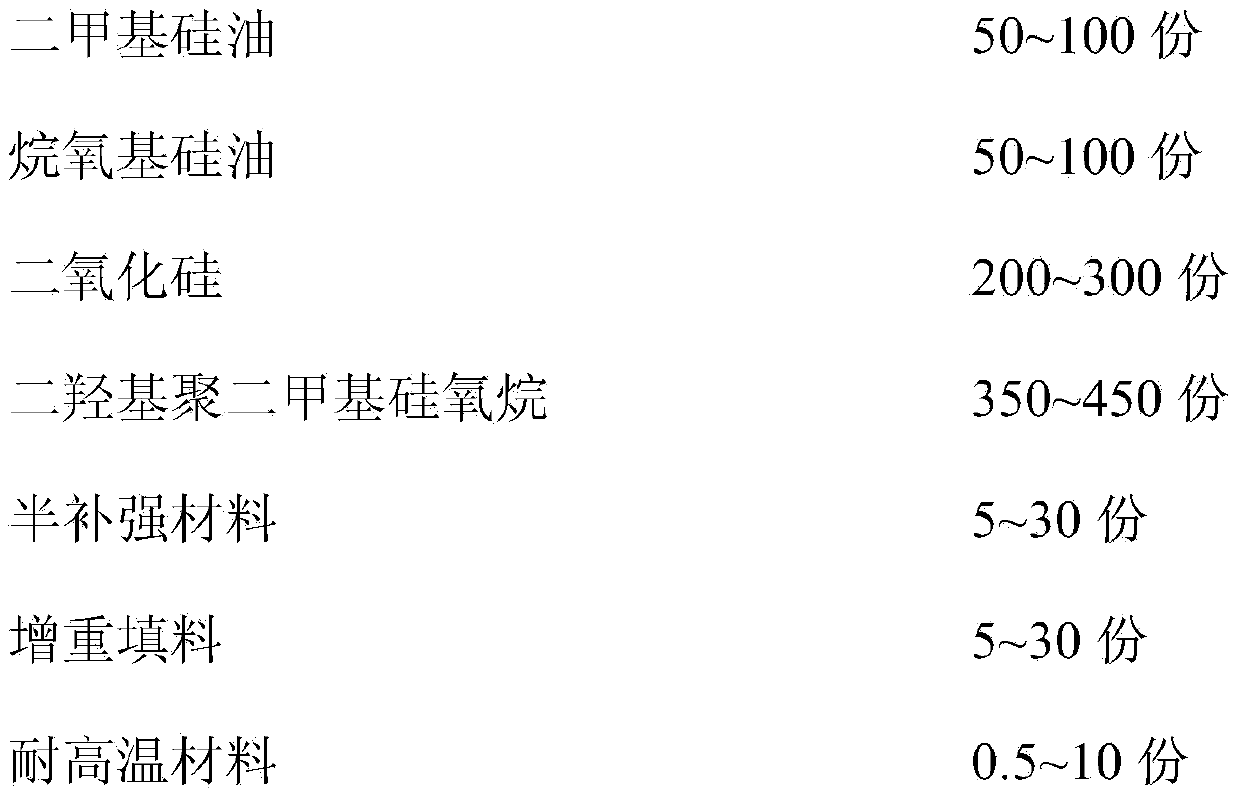

[0072] A kind of condensation mold silicone rubber, described mold silicone rubber comprises A component and B component, and it comprises by weight parts:

[0073] Component A:

[0074]

[0075] Component B:

[0076] Catalyst 10 parts

[0077] 30 parts of cross-linking agent

[0078] Accelerator 2 parts;

[0079] The weight ratio of the A component and the B component is 100:1.5.

[0080] The simethicone is selected from simethicone with a viscosity of 100 cps.

[0081] The alkoxy silicone oil is selected from the alkoxy silicone oil with a viscosity of 300 cps.

[0082] The silica is precipitated silica.

[0083] The dihydroxy polydimethylsiloxane is selected from dihydroxy polydimethylsiloxanes with a viscosity of 1000 cps.

[0084] The semi-reinforcing filler is silicon micropowder.

[0085] The weight-increasing filler is heavy calcium carbonate.

[0086] The high temperature resistant material is iron red.

[0087] The catalyst is dibutyl tin diacetate.

[...

Embodiment 2

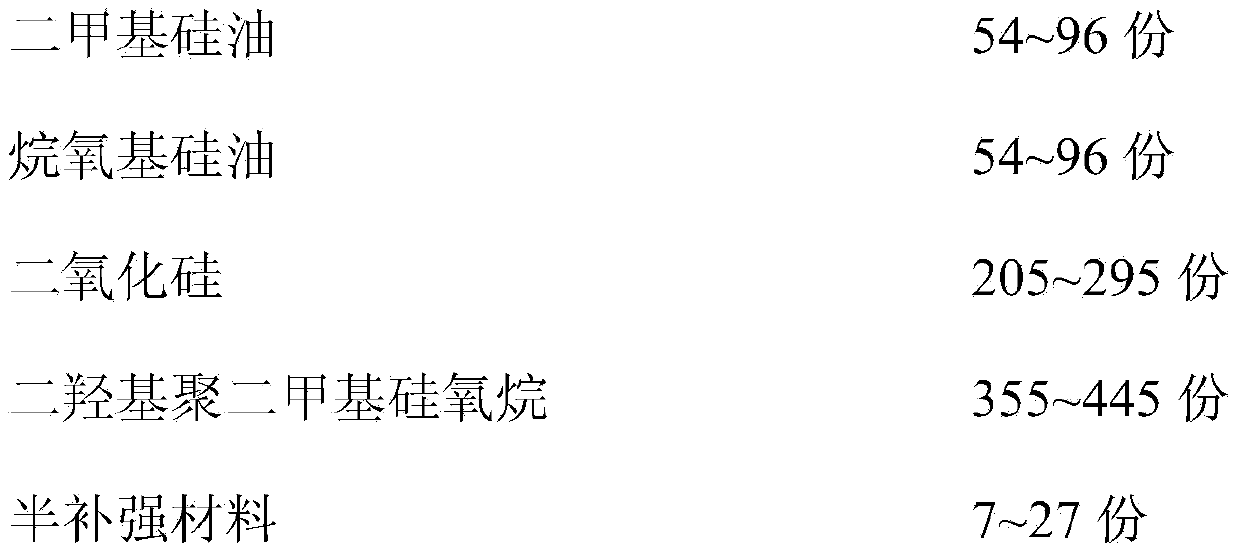

[0095] A kind of condensation mold silicone rubber, described mold silicone rubber comprises A component and B component, and it comprises by weight parts:

[0096] Component A:

[0097]

[0098] Component B:

[0099] Catalyst 40 parts

[0100] Cross-linking agent 80 parts

[0101] Accelerator 10 parts;

[0102] The weight ratio of the A component and the B component is 100:3.

[0103] The simethicone oil is selected from simethicone oils with a viscosity of 1000 cps.

[0104] The alkoxy silicone oil is selected from alkoxy silicone oils with a viscosity of 1500 cps.

[0105] The silica is precipitated silica.

[0106] The dihydroxypolydimethylsiloxane is selected from dihydroxypolydimethylsiloxanes with a viscosity of 100000 cps.

[0107] The semi-reinforcing filler is a mixture of silicon micropowder, zinc oxide and titanium dioxide.

[0108] The weight-increasing filler is a mixture of heavy calcium carbonate, light calcium carbonate, kaolin and montmorillonite. ...

Embodiment 3

[0118] A kind of condensation mold silicone rubber, described mold silicone rubber comprises A component and B component, and it comprises by weight parts:

[0119] Component A:

[0120]

[0121] Component B:

[0122] Catalyst 22 parts

[0123] 54 parts of cross-linking agent

[0124] Accelerator 5 parts;

[0125] The weight ratio of the A component and the B component is 100:2.1.

[0126] The simethicone oil is selected from simethicone oil with a viscosity of 563 cps.

[0127] The alkoxy silicone oil is selected from alkoxy silicone oils with a viscosity of 876 cps.

[0128] The silica is precipitated silica.

[0129] The dihydroxy polydimethylsiloxane is selected from dihydroxy polydimethylsiloxanes with a viscosity of 25000 cps.

[0130] The semi-reinforcing filler is zinc oxide.

[0131] The weight-increasing filler is light calcium carbonate.

[0132] The high temperature resistant material is iron yellow.

[0133] The catalyst is stannous octoate.

[0134]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com