Magnesium-aluminum-zinc wrought magnesium alloy containing calcium and rare-earth samarium

A deformed magnesium alloy and rare earth technology, applied in the field of metal materials, can solve the problems of unfavorable alloy mechanical properties and the impact of Mg-Al-Zn magnesium alloy performance, etc., achieve good solid solution strengthening conditions, improve alloy oxidation resistance, The effect of fine microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

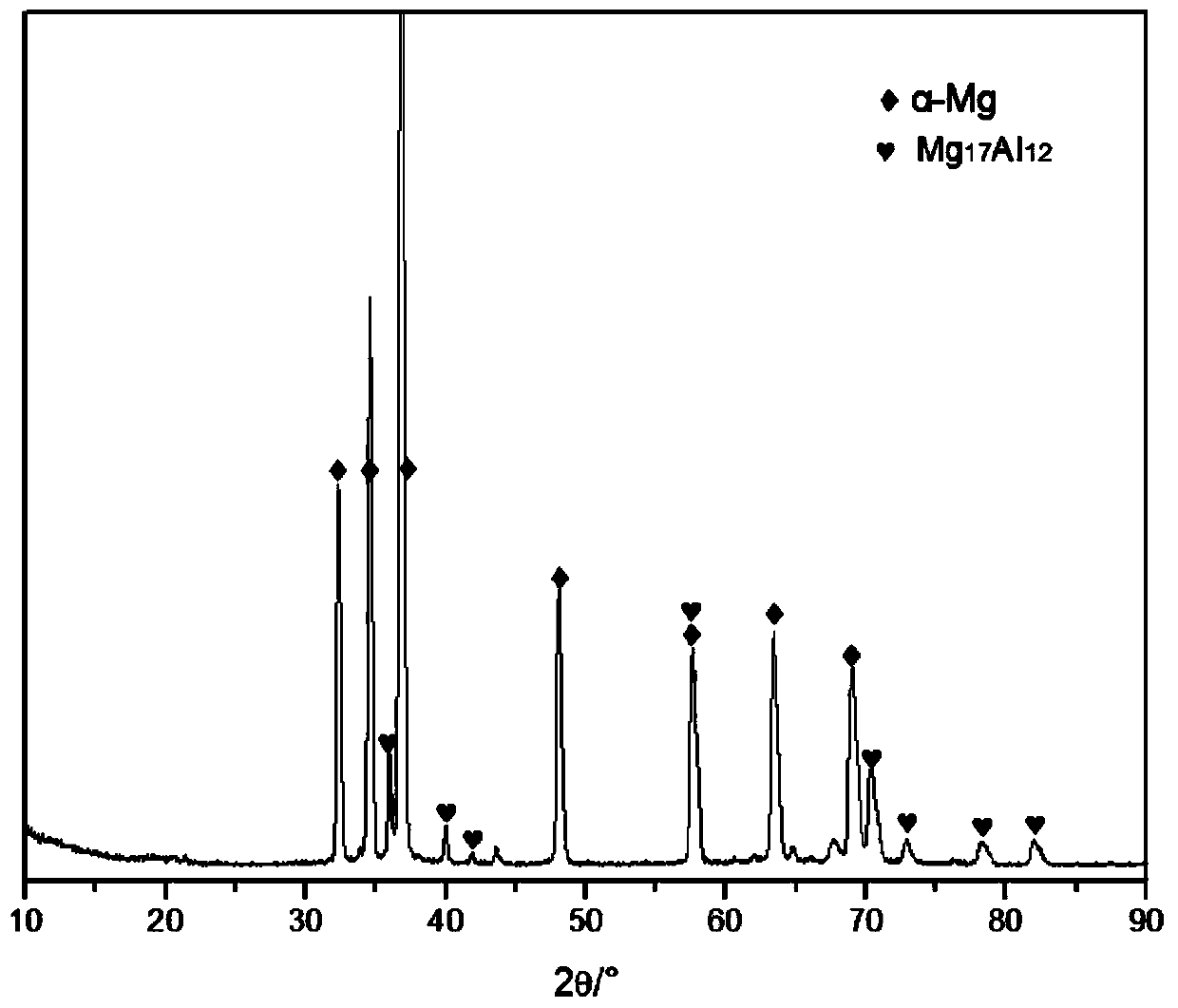

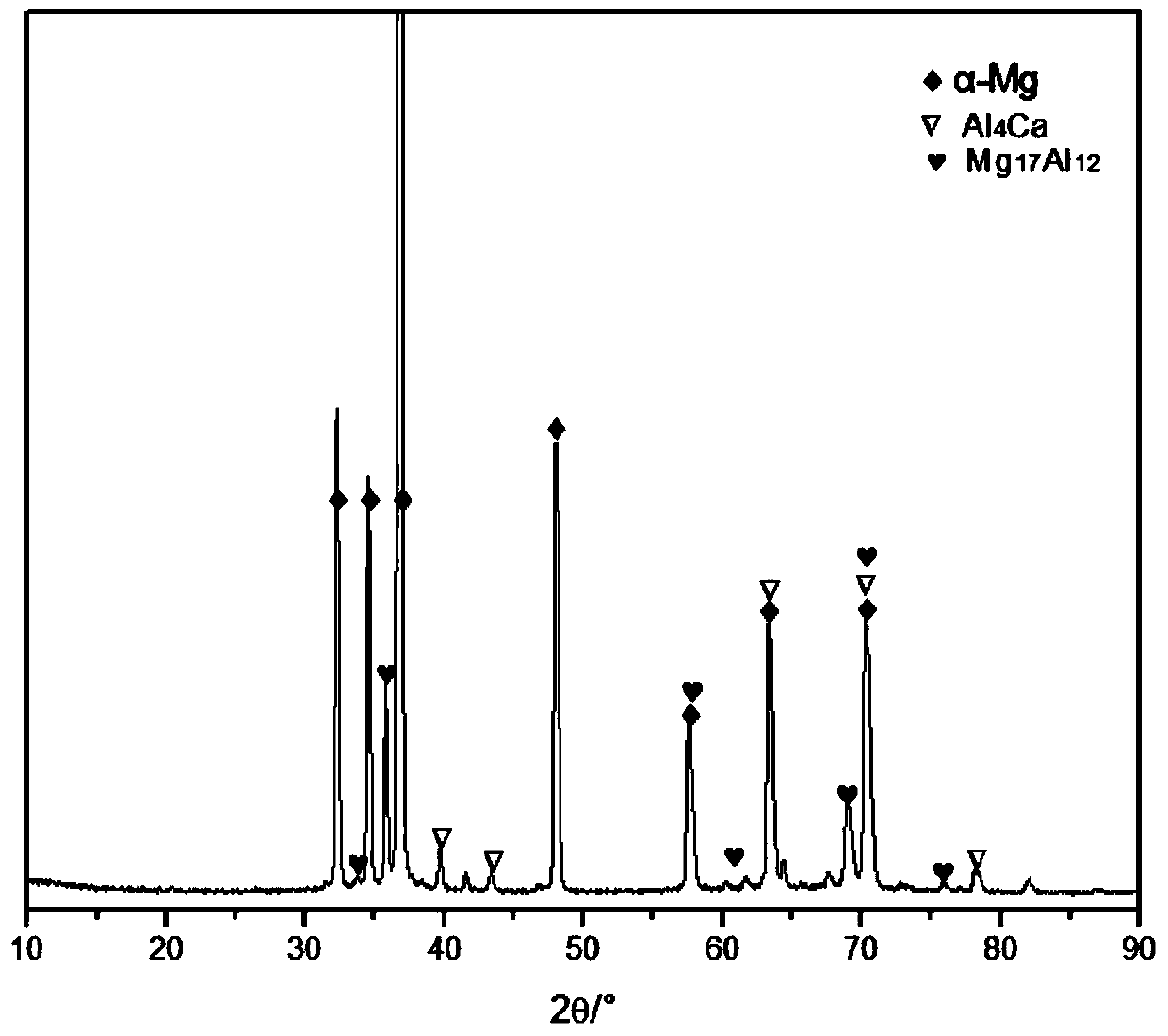

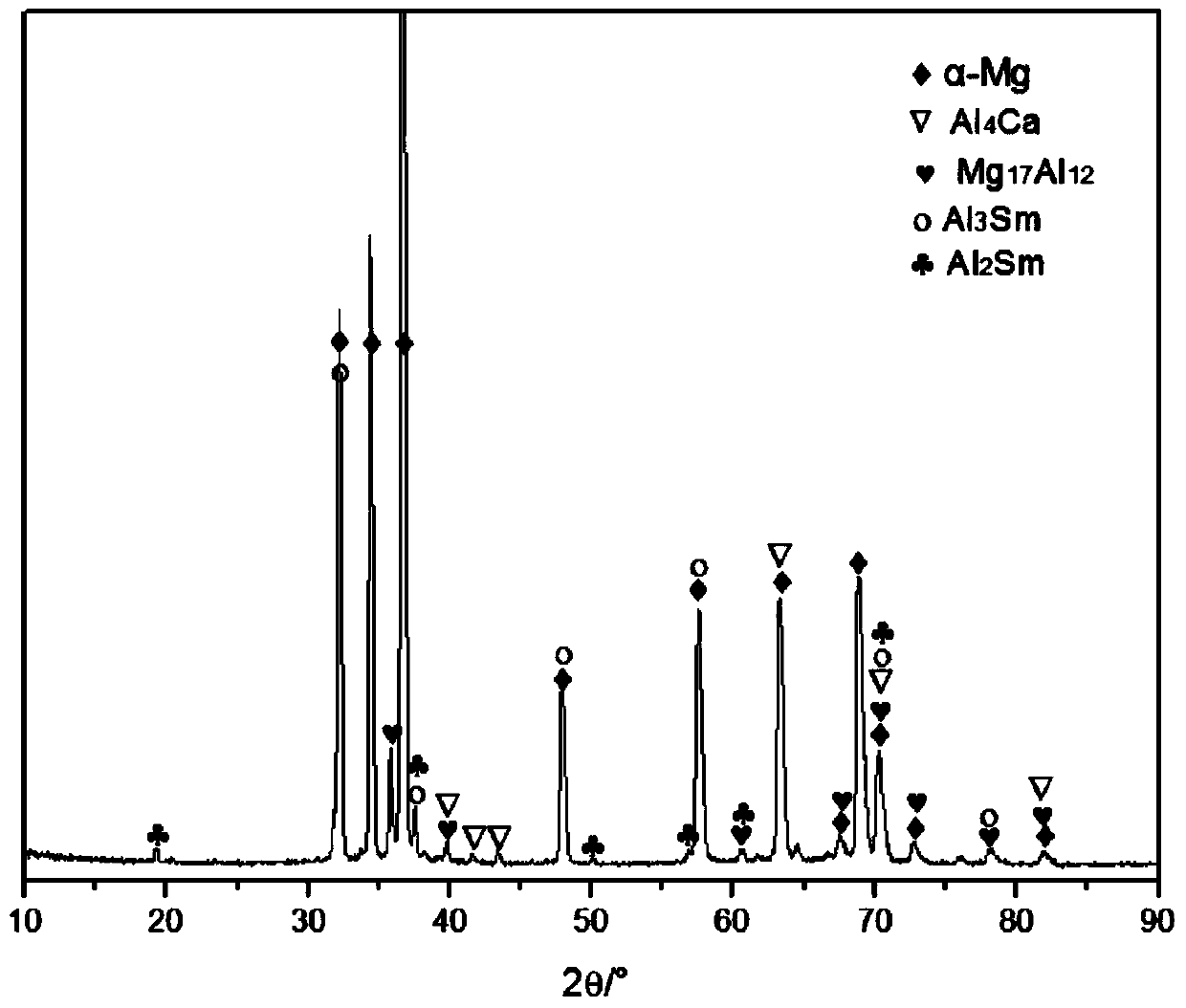

[0038] The composition of the magnesium-aluminum-zinc deformed magnesium alloy containing calcium and rare earth samarium of the present invention is shown in Table 1 (the following are mass percentages):

[0039] Table 1

[0040]

[0041] According to the proportions in Examples 1-6, the raw materials of the present invention are respectively taken, and the preparatory work before preparing the alloy includes: polishing the surface of the raw material until it is bright, so as to remove the oxide skin on the surface of the material. Clean stainless steel crucibles to remove other impurities. Fill the raw materials into the stainless steel crucible set in the graphite crucible. Put the graphite crucible with raw materials into the vacuum induction furnace, vacuumize and fill with argon protection during the melting process to prevent the oxidation of magnesium and alloy elements. When the alloy in the crucible is completely melted and kept warm for 5 minutes, put the stainl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com