Detection method for specific capacity of lithium ion battery negative electrode active material after circulation

A negative electrode active material and lithium-ion battery technology, applied to battery electrodes, measuring electrical variables, circuits, etc., can solve the problems of limited sample size, increased sample size, increased solvent amount, etc., to achieve reliable specific capacity testing and reduce the amount used , the effect of improving controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

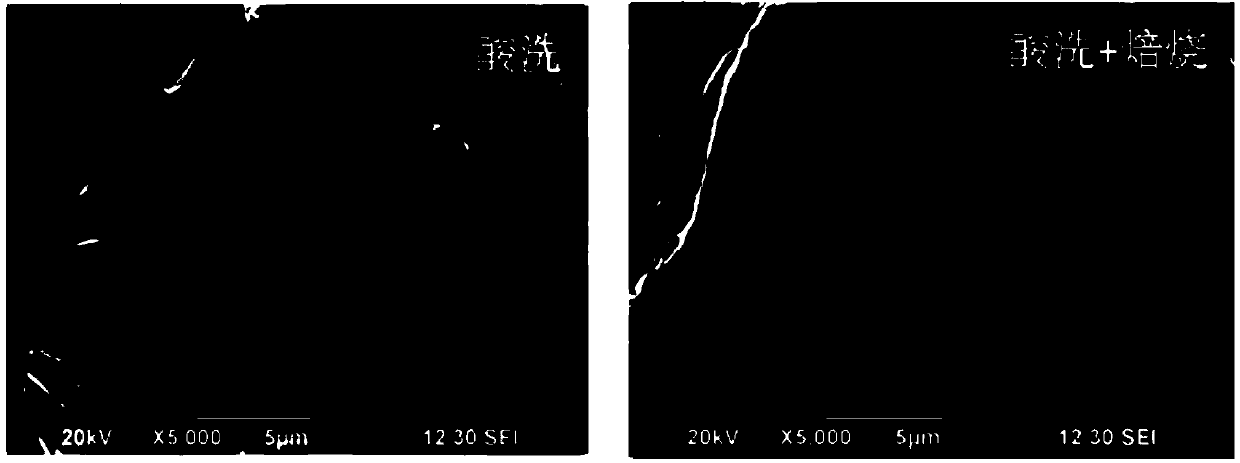

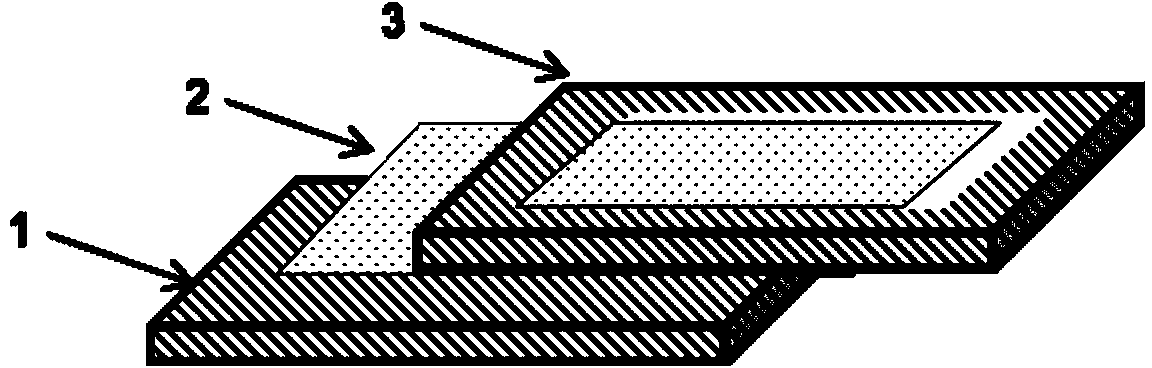

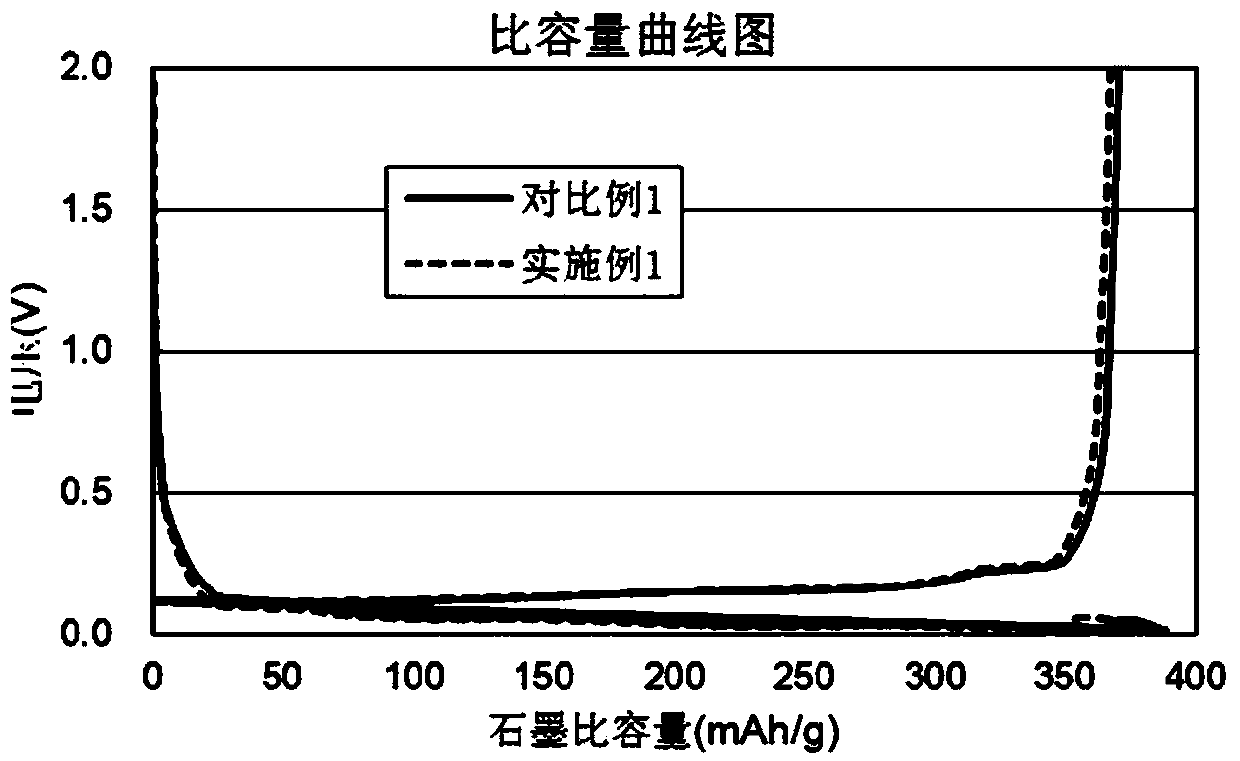

[0033]Extraction of the negative electrode active material of the lithium-ion battery after cycling: Discharge the 506971 lithium-ion battery with H-type graphite as the negative electrode active material and cycle it for 1 week at 0.1C until the voltage is lower than 2V, disassemble it in a dry room and take out the negative electrode sheet After that, rinse and soak it with dimethyl carbonate (DMC) immediately, then take it out and dry it; put the dried negative electrode piece into 0.1mol / L hydrochloric acid solution, and ultrasonically treat it for 0.5h. At this time, the negative electrode The negative electrode diaphragm of the sheet falls off into the hydrochloric acid solution and the material of the negative electrode diaphragm is evenly dispersed in the hydrochloric acid solution, and the current collector of the negative electrode sheet is taken out; the solid-liquid separation is obtained by suction filtration, and a solid substance is obtained; repeated rinsing with...

Embodiment 2

[0044] Extraction of the negative electrode active material of the lithium-ion battery after cycling: discharge the 506971 lithium-ion battery with H-type graphite as the negative electrode active material after 600 cycles at 0.1C until the voltage is lower than 2V, disassemble it in a dry room and take out the negative electrode sheet After that, rinse and soak with ethyl acetate (EA) immediately, then take it out and dry it; put the dried negative electrode piece into 0.5mol / L sulfuric acid solution, and ultrasonically treat it for 0.5h. At this time, the negative electrode piece The negative electrode diaphragm falls off into the sulfuric acid solution and the material of the negative electrode diaphragm is evenly dispersed in the sulfuric acid solution, and the current collector of the negative electrode sheet is taken out; suction filtration separates the solid from the liquid to obtain a solid substance; the solid substance is repeatedly rinsed with deionized water , unti...

Embodiment 3

[0051] Extraction of the negative electrode active material of the lithium-ion battery after cycling: discharge the 506971 lithium-ion battery with H-type graphite as the negative electrode active material after 800 cycles at 0.1C until the voltage is lower than 2V, disassemble it in a dry room and take out the negative electrode sheet After that, rinse and soak it with dimethyl carbonate (DMC) immediately, then take it out and dry it; put the dried negative electrode piece into 0.2mol / L hydrochloric acid solution, and ultrasonically treat it for 0.5h. At this time, the negative electrode The negative electrode diaphragm of the sheet falls off into the hydrochloric acid solution and the material of the negative electrode diaphragm is evenly dispersed in the hydrochloric acid solution, and the current collector of the negative electrode sheet is taken out; the solid-liquid separation is obtained by suction filtration, and a solid substance is obtained; repeated rinsing with deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com