Preparation method of foamed graphene-ZnO composite material

A composite material and graphene technology, applied in the field of nanomaterial manufacturing, can solve problems such as complex process and graphene agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Dissolve 30 mg each of the raw materials graphene oxide and zinc fluoride in 60 ml of deionized water, mix them uniformly by ultrasonic waves, then centrifuge and clean them;

[0017] Add the obtained product to 60ml of deionized water, re-disperse it evenly by ultrasonic, and then freeze and dry the solution with a refrigeration compressor;

[0018] The obtained product was heated to 300°C in air for 10 hours to obtain a foamed graphene-ZnO composite material.

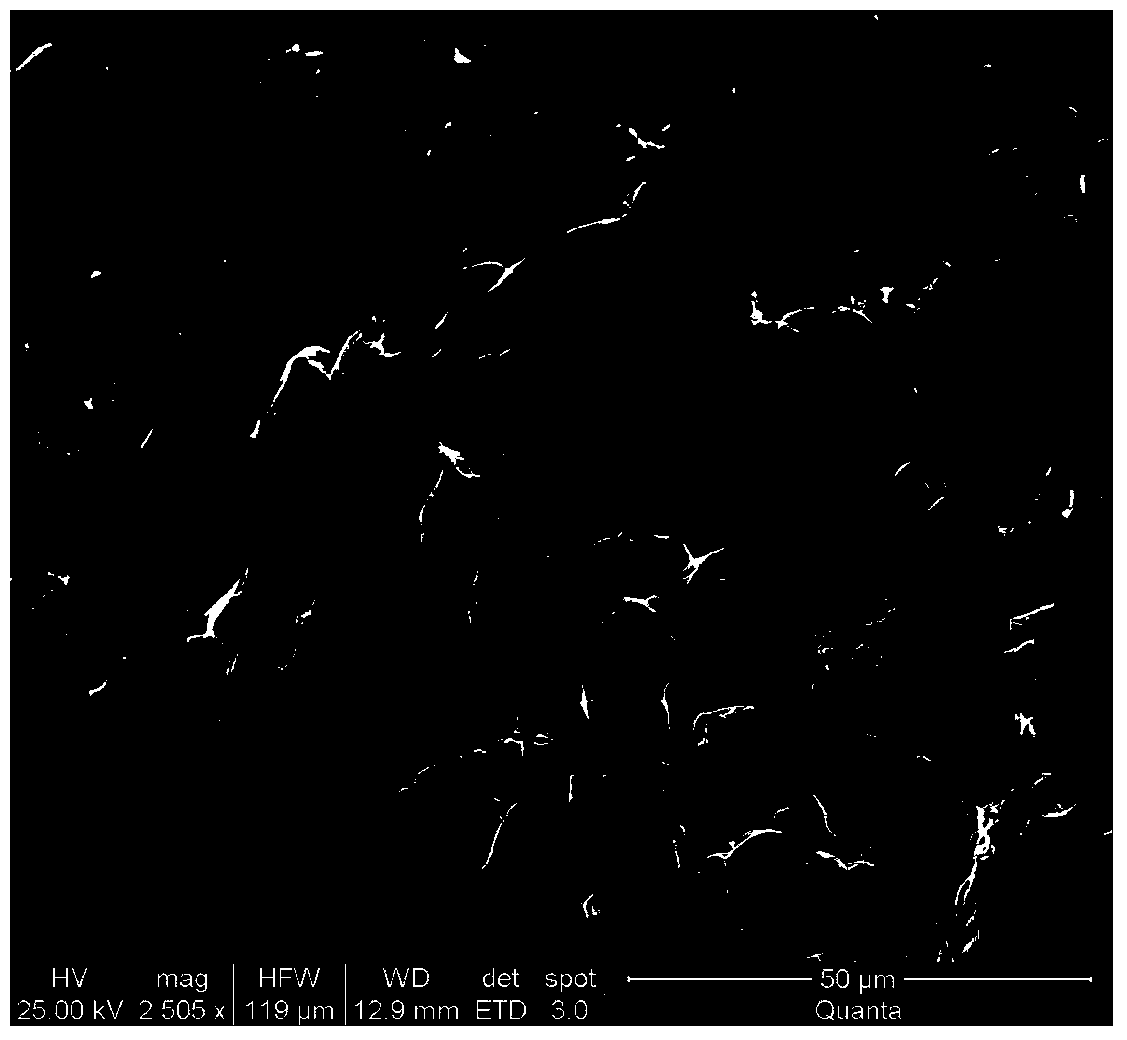

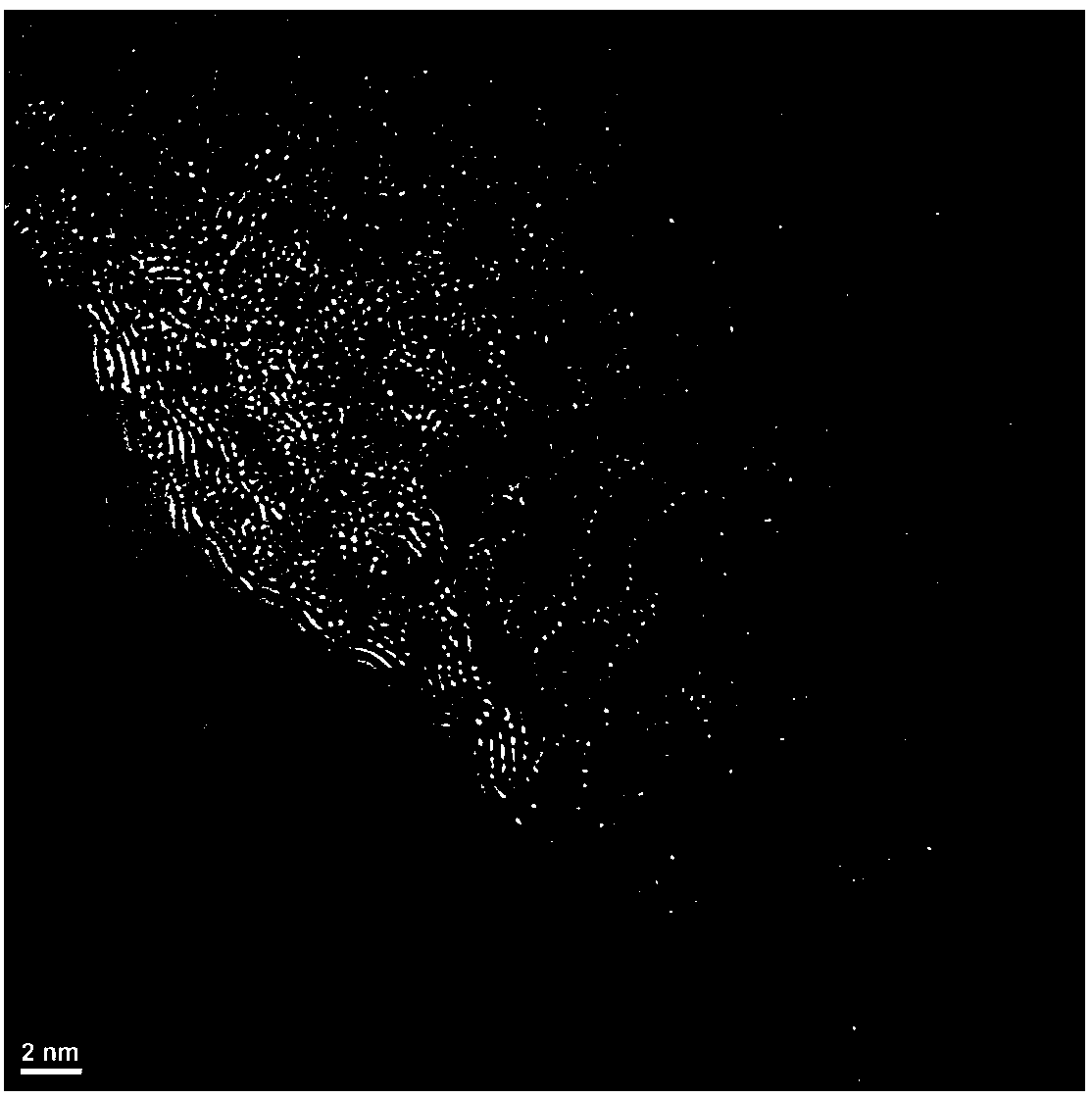

[0019] The product was characterized by scanning electron microscopy, and the results were as follows: figure 1 As shown, it can be seen that the composite material is a foam porous structure. The product was characterized by transmission electron microscopy, and the results were as follows: figure 2 As shown, it can be seen that ZnO nanoparticles are embedded on the graphene surface, and the ZnO particle size is about 5 nm.

Embodiment 2

[0021] Dissolve 10 mg of graphene oxide and 20 mg of zinc nitrate in 30 ml of deionized water, stir and mix evenly, then centrifuge and clean;

[0022] The obtained product was redispersed into 30ml of deionized water and stirred evenly, and then the obtained solution was frozen with liquid nitrogen to obtain a solid, which was then transferred to a freeze dryer for freeze drying;

[0023] The obtained product was heated to 500° C. for 10 minutes in oxygen to obtain a foamed graphene-ZnO composite material.

[0024] The obtained sample microscopic characterization results are similar to Example 1.

Embodiment 3

[0026] Take 100mg of graphene oxide and 10mg of zinc acetate and dissolve them in 100ml of deionized water, mix them uniformly by ultrasonic, then centrifuge and clean them;

[0027] The obtained product was redispersed into 100ml deionized water, then subjected to refrigeration compressor freezing and drying;

[0028] The obtained product was heated to 1050° C. for 10 seconds in air to obtain a foamed graphene-ZnO composite material.

[0029] The obtained sample microscopic characterization results are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com