Method for preparing nano diamonds by using direct-current arc process

A nano-diamond and DC arc technology, which is applied in the direction of diamond, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of difficult reaction conditions, low diamond output, complex reaction process, etc., and achieve the improvement of production efficiency , simple process, avoiding the effect of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Take a mixture of 85.5% by mass of micron-sized nickel powder, 4.5% of silicon powder and 10% of graphite powder, grind it evenly, press it into a block, and put it into a graphite crucible as a composite anode target. The graphite rod is the cathode. The pressure in the reaction chamber was pumped to about 10 -2 Pa, fill hydrogen and argon at a ratio of 6:1 to 10 5 Pa. Turn on the cooling water system, turn on the power and start the arc, adjust the current and the distance between the two poles to keep the arc stable, fully evaporate the bulk target in the crucible, form gaseous atoms and ions, and aggregate into nanometer after nucleation, growth, and condensation processes. The particles are deposited on the wall of the reaction chamber, and the nanopowder is collected through a passivation process.

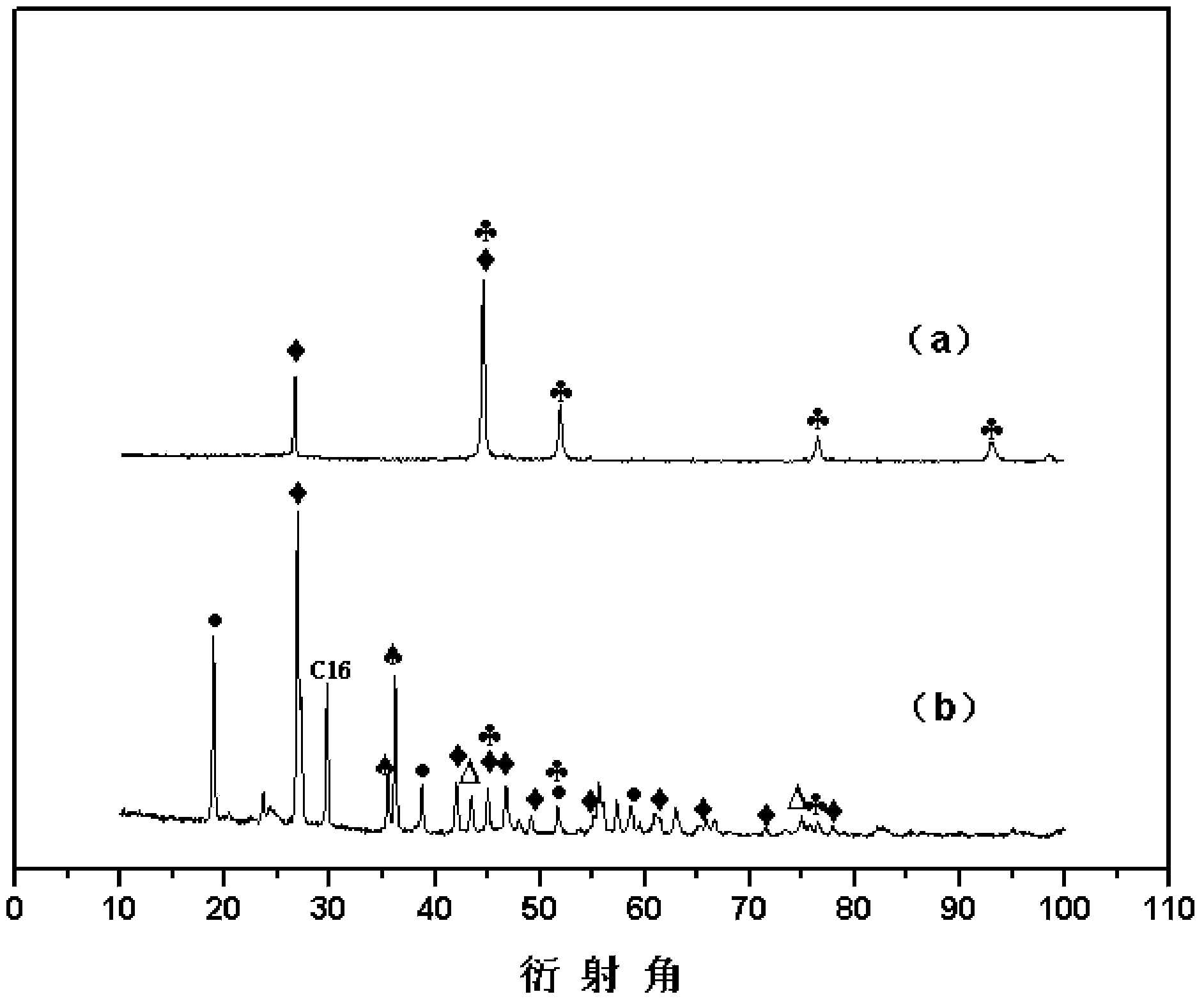

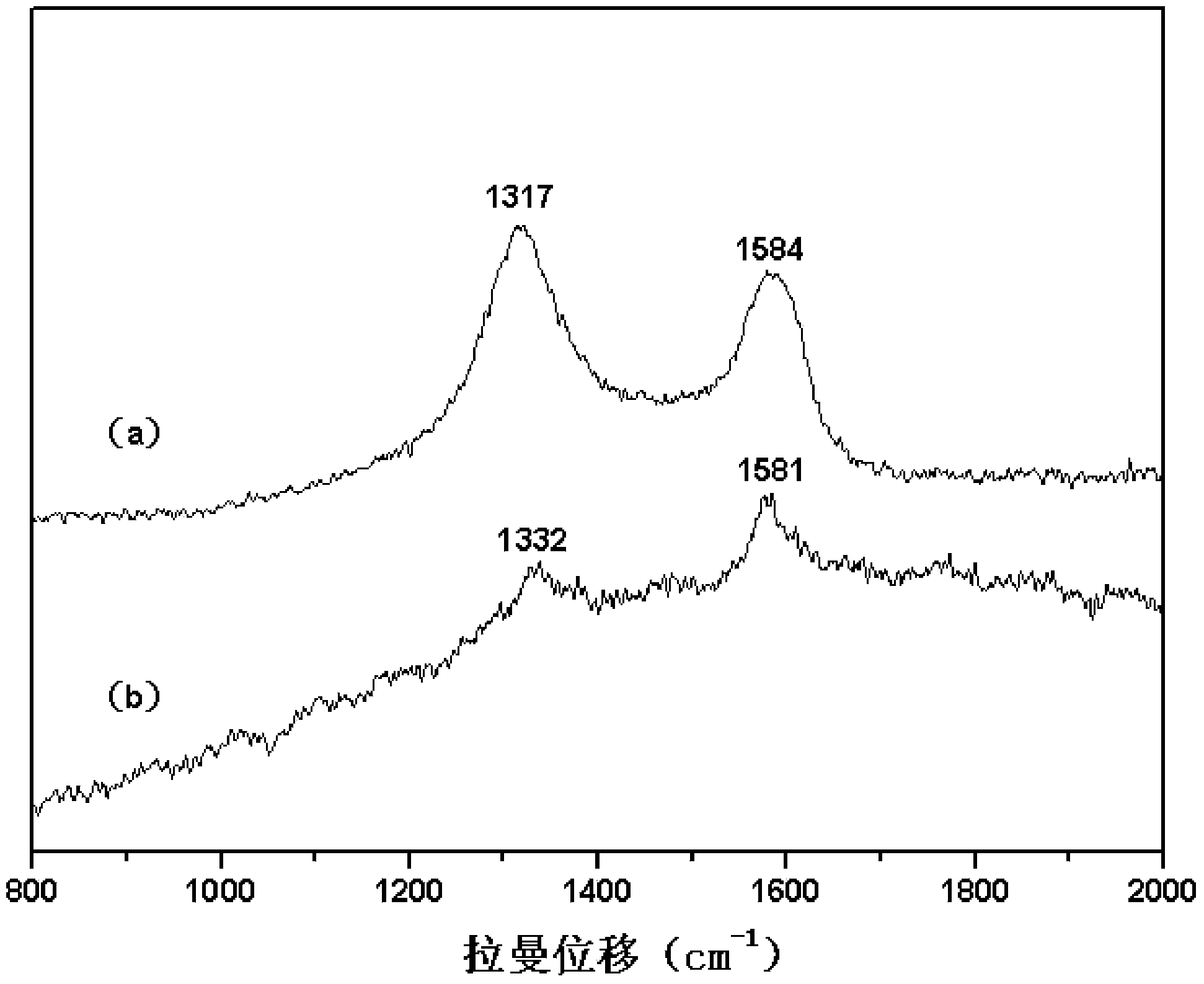

[0029] The XRD comparative collection of collections before and after the purification of embodiment gained nano-diamond blank is as figure 1 As shown in (a) and (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com