Electrode subassembly, preparation method thereof and lithium secondary battery

A lithium secondary battery and electrode assembly technology, which is applied in the field of energy storage device manufacturing, can solve the problems of low material utilization, large battery volume, high manufacturing and use costs, etc., achieve high electrode assembly volume, improve electrical performance, and improve yield rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

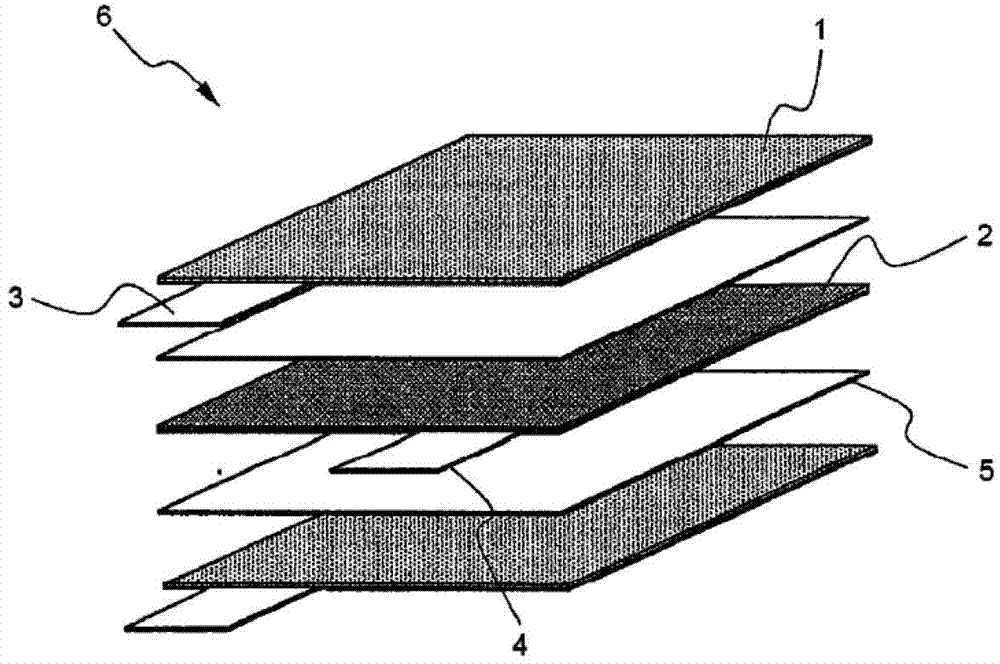

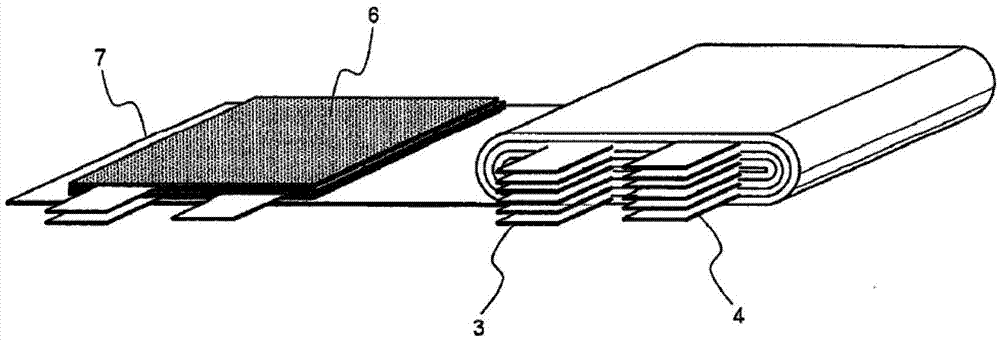

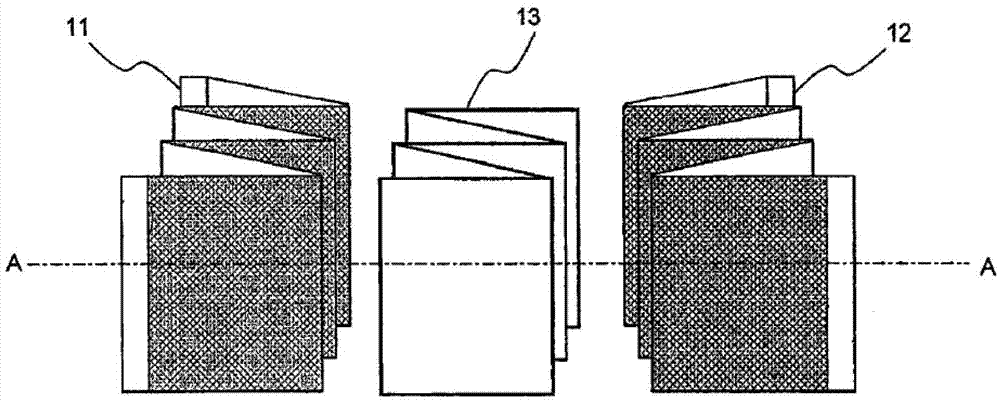

[0063] Figure 4 is a schematic diagram of the electrode assembly of this embodiment before assembly, and Figure 5 After the electrode assembly is assembled, along the Figure 4 A vertical cross-sectional view taken along line A-A in . Such as Figure 4 and Figure 5 As shown, in the electrode assembly 100, the cathode plate 110 is a discontinuous independent insert, and the anode plate 120 is continuously bent into a zigzag vertical section. The cathode plate 110 includes a cathode current collector 111 and a cathode active material 112 coated on both sides of the cathode current collector 111 , and the anode plate 120 includes an anode current collector 121 and an anode active material 122 coated on both sides of the anode current collector 121 . Each cathode plate 110 is respectively wrapped in a diaphragm bag made of polypropylene porous membrane. One end of the diaphragm bag is open, and the two sides of the wrapped cathode plate 110 become the isolation layer 130 . ...

Embodiment 2

[0072] Figure 9 Schematic illustration of the electrode assembly provided for this example before assembly. Figure 10 After the above electrode assembly is assembled, along Figure 9 A vertical cross-sectional view taken along line A-A in . Such as Figure 9 and Figure 10 As shown, in the electrode assembly 200, the cathode plate 210 is a discontinuous independent insert, and the anode plate 220 is continuously bent into a zigzag vertical section. The cathode plate 210 includes a cathode current collector 211 and a cathode active material 212 coated on both sides of the cathode current collector 211 , and the anode plate 220 includes an anode current collector 221 and an anode active material 222 coated on both sides of the anode current collector 221 .

[0073] The settings of the contact area 223 and the bending area 224 are the same as those in the first embodiment. Different from Embodiment 1, the separator 230 is a strip-shaped polyethylene porous film with the same...

Embodiment 3

[0079] This embodiment provides a method for manufacturing a lithium secondary battery, using the electrode assembly provided in Embodiment 1 or Embodiment 2. The specific manufacturing method is as follows: the above-mentioned electrode assembly is placed in an aluminum foil package, and then an electrolyte is injected and packaged. The electrolyte includes 1M LiPF 6 A mixed solution of ethylene carbonate and methyl ethyl carbonate (weight ratio 1:2) was prepared into an aluminum-cased square battery.

[0080] There is no unused space in the lithium secondary battery container prepared in this embodiment, the energy density is high, and short circuit is not easy to occur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com